+86 19720579616

+86 19720579616

Zalo

Zalo

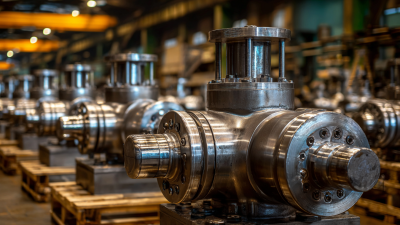

In the intricate landscape of industrial applications, the selection of the right components can significantly impact operational efficiency and safety standards. Among these critical components, Forged Steel Valves are renowned for their superior strength and durability, making them essential for high-pressure and high-temperature environments. According to a recent market analysis by MarketsandMarkets, the global valve market is projected to reach USD 85.5 billion by 2027, with a notable increase in the demand for high-performance forged valves across various industries, including oil and gas, power generation, and water treatment.

With the growing emphasis on optimizing industrial processes and maintaining stringent safety regulations, the importance of choosing the appropriate Forged Steel Valves cannot be overstated. This ultimate guide aims to provide comprehensive insights into the factors influencing this crucial choice, ensuring that professionals are well-equipped to make informed decisions that align with their operational needs.

When selecting forged steel valves for industrial applications, a few key factors should be emphasized to ensure optimal performance and longevity. Firstly, compatibility with the operating environment is crucial; valves exposed to corrosive substances or extreme temperatures must be chosen carefully. Recent findings highlight the importance of selecting appropriate protective coatings to combat common corrosion types, especially in wastewater systems. These coatings not only enhance durability but also lower maintenance costs, making them a vital consideration for industries facing harsh conditions.

Additionally, the specific functionality of the valve is paramount. Different applications—whether in oil and gas, chemicals, or general manufacturing—demand valves that can handle varying pressure levels, flow rates, and operational cycles. The market for forged steel split body ball valves is anticipated to grow significantly, indicating a rising demand for reliable and efficient options. As industries continue to innovate and adapt to changing conditions, understanding the nuances of valve selection will play a pivotal role in maintaining system efficiency and safety.

| Factor | Description | Importance Level |

|---|---|---|

| Material Type | Selection of appropriate material based on application requirements such as pressure, temperature, and type of fluid. | High |

| Size and Specifications | Ensure valve size matches pipeline and system specifications to prevent leaks and operational issues. | Medium |

| Pressure Rating | Select valves that can handle the maximum pressure requirements of the application to ensure safety and functionality. | Critical |

| Temperature Range | Determine if the valve materials can withstand the operational temperature variations. | High |

| Flow Characteristics | Assess how well the valve design facilitates the intended flow profile for efficiency and performance. | Medium |

| End Connections | Ensure compatibility of valve end connections with existing piping systems. | Important |

| Certification and Standards | Verify that the valves meet industry standards and certifications for quality and reliability. | Critical |

| Cost and Budget | Evaluate the cost against the budget while considering the long-term value and maintenance costs. | Medium |

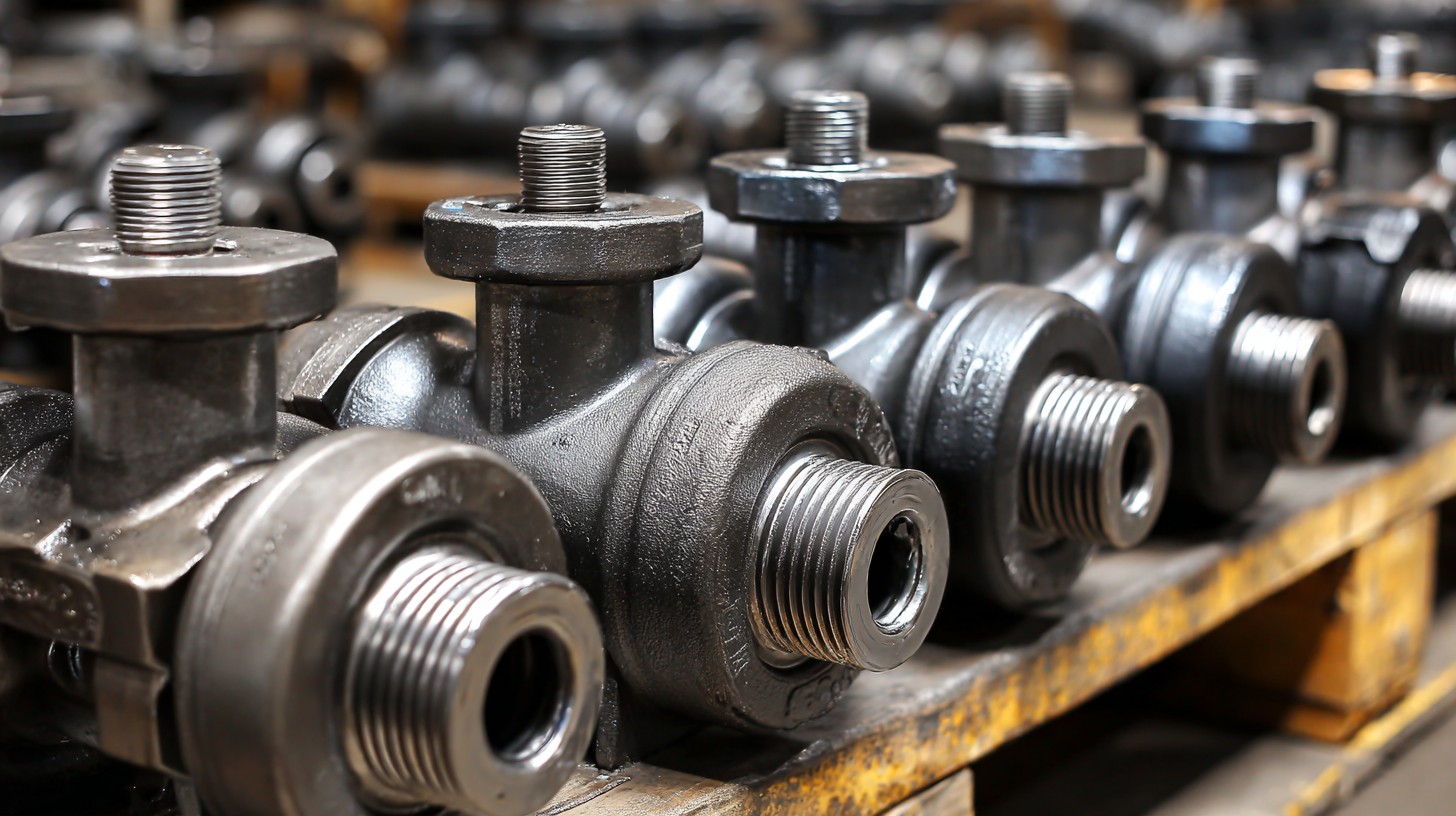

When it comes to industrial applications, understanding the different types of forged steel valves is crucial for ensuring efficiency and safety in operations.

Forged steel valves are known for their superior durability and high-pressure resistance, making them ideal for critical applications. The primary types of forged steel valves include gate valves,

globe valves, ball valves, and check valves, each designed for specific purposes. For example,

gate valves are commonly used for on-off service, providing minimal flow resistance, while globe valves are preferred for throttling and regulating flow due to their design.

Ball valves, on the other hand, are favored for their quick operation and tight sealing capabilities, making them suitable for applications requiring rapid shut-off.

Check valves play a vital role in preventing backflow, ensuring that the fluid flows in only one direction. Choosing the right type of forged steel valve involves evaluating the specific needs of the application, such as

pressure, temperature, and flow characteristics. Understanding these distinctions allows engineers and operators to select the most appropriate valve,

contributing to the overall efficiency and reliability of industrial systems.

When selecting forged steel valves for industrial applications, understanding the key material properties is essential for optimizing performance. Forged steel, due to its superior mechanical properties, offers high tensile strength and resistance to wear and corrosion, making it a preferred choice in demanding environments. According to a report by the Global Forged Steel Valve Market, the tensile strength of forged steel valves can exceed 1500 MPa, significantly outperforming cast counterparts, particularly in high-pressure applications.

Moreover, the impact of temperature on valve performance cannot be underestimated. Forged steel valves maintain their integrity and functionality in extreme temperatures, ranging from -196°C to 600°C, as noted in the API 600 specification. This resilience is critical in industries such as oil and gas, where operational conditions can fluctuate dramatically. Furthermore, the fine-grained structure of forged steel contributes to enhanced toughness and fatigue resistance, essential for applications involving cyclic loads.

Ultimately, selecting the right forged steel valve requires a keen understanding of these material properties to ensure efficiency and reliability in industrial operations.

When it comes to selecting forged steel valves for industrial applications, adhering to common industry standards and certifications is paramount. Several key standards govern the manufacturing and testing of these valves, ensuring they are suitable for high-pressure and high-temperature environments. The American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) are two primary organizations that establish guidelines. For instance, ASME’s Boiler and Pressure Vessel Code (BPVC) and API 600 standards provide crucial specifications for material properties, design, and performance characteristics, which can significantly impact the reliability of the valves in demanding applications.

Moreover, certifications such as ISO 9001 emphasize quality management systems, ensuring that manufacturers consistently produce valves that meet stringent quality standards. A recent industry report from the International Organization for Standardization (ISO) indicates that companies adhering to ISO standards experience a 20% increase in operational efficiency, which reflects the importance of compliance not only for safety but also for performance. In addition, compliance with industry standards like ASTM A105 for carbon steel and ASTM A182 for alloy steel can help ensure long-lasting performance and resistance to environmental factors such as corrosion and high pressure. Therefore, investing time in understanding these standards is essential for making informed decisions when selecting forged steel valves for industrial applications.

To ensure the longevity of forged steel valves in industrial applications, regular maintenance is crucial. Forged steel valves, known for their strength and durability, still require routine checks to prevent leaks, corrosion, and performance degradation. One vital practice is to conduct visual inspections to identify any signs of wear or damage. This includes checking for surface rust or pitting, which can compromise the integrity of the valve. Additionally, ensuring that the valve seats and seals are properly lubricated helps reduce friction and wear, prolonging their lifespan.

Another key aspect of maintenance is implementing a proactive valve exercise routine. Regularly opening and closing the valves, even if they are not in active use, can help identify any potential sticking issues before they become critical. It is also essential to maintain the appropriate operational conditions, as extreme temperatures and pressures can adversely affect the valve’s performance. By adhering to a scheduled maintenance plan and promptly addressing any issues, industries can maximize the efficiency and longevity of their forged steel valves, significantly reducing the likelihood of unexpected failures and costly downtimes.

This bar chart illustrates the maintenance frequency of forged steel valves across different industrial applications based on survey data. Regular maintenance is essential for ensuring the longevity and effective operation of these valves.