0102030405

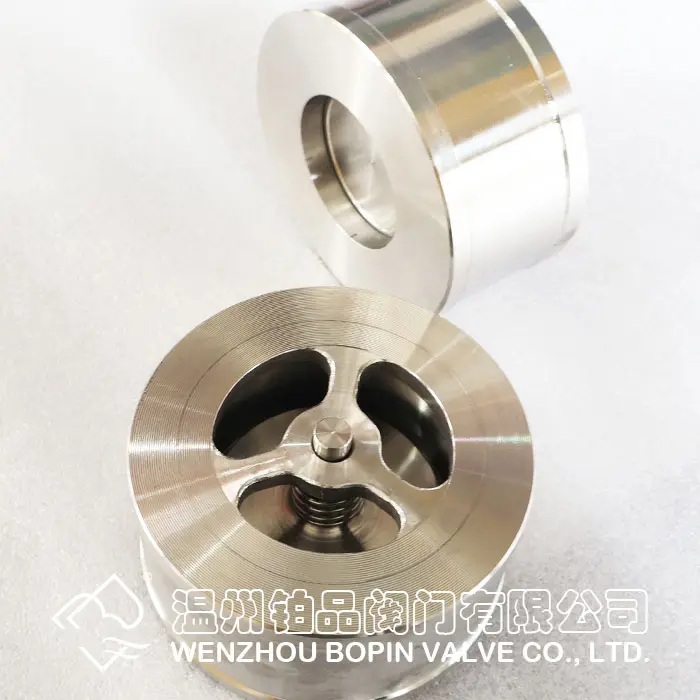

WAFER TYPE SPRING LOADED LIFT CHECK VALVE

1. What is an API 594 Forged Steel Wafer Type Lift Check Valve?

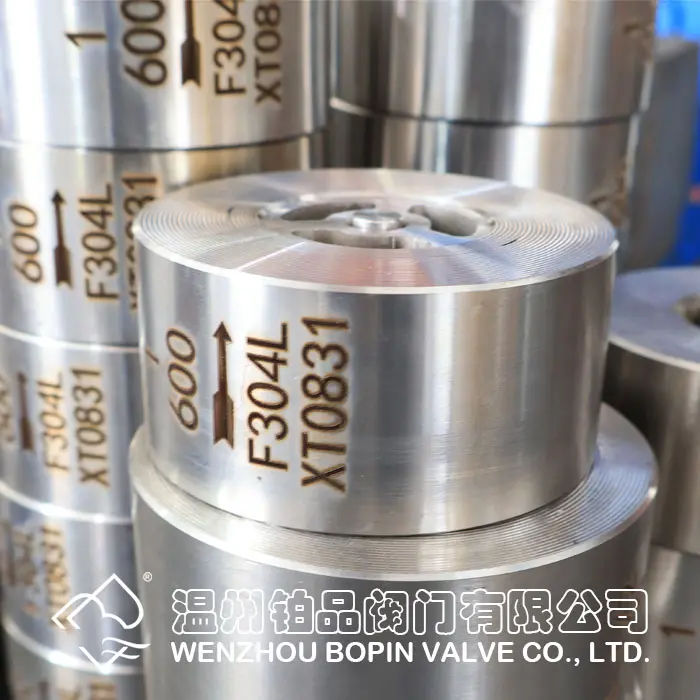

API 594 Standard

API 594 is a standard published by the American Petroleum Institute that outlines the design, testing, and material requirements for wafer-style check valves. Wafer-type check valves are compact, lightweight valves that are installed between flanges, making them ideal for systems with limited space. The API 594 standard ensures that these valves meet the performance expectations required in the oil, gas, and chemical industries.

The standard provides specifications for different types of check valves, including swing check valves and lift check valves. A lift check valve is a specific type of check valve where the disc or valve element moves vertically to open and close, typically against a spring or pressure differential.

Forged Steel 904L

The term "forged steel" refers to the manufacturing process, where the steel is forged under heat and pressure to create a dense, strong material. 904L stainless steel is a high-alloy austenitic stainless steel known for its excellent corrosion resistance, particularly in harsh environments such as acidic media, seawater, and chemical applications. The combination of forged steel and 904L provides a durable valve body that can withstand extreme conditions without compromising performance.

Wafer Type Design

A wafer-type valve refers to the design of the valve body, which is characterized by its flat, lightweight, and compact shape. These valves are sandwiched between two flanges in a piping system, reducing space and weight requirements. The wafer design is ideal for installations where space is limited or where flanged connections are impractical. The simplicity of the wafer design also reduces installation and maintenance costs.

2. Key Features of the API 594 Forged Steel 904L Wafer Type Lift Check Valve

Lift Check Valve Mechanism

The lift check valve operates by allowing fluid to flow in one direction while preventing reverse flow. The valve's disc or closure element moves vertically in response to fluid pressure. When the pressure from the flow is higher than the opposing pressure, the valve opens, allowing the flow to pass through. When the flow reverses or the pressure drops, the disc closes, preventing backflow. The lift check mechanism ensures that the valve's action is smooth, reducing the risk of water hammer and improving the overall efficiency of the system.

Forged Steel 904L Construction

The use of 904L stainless steel in the valve construction provides several advantages:

Corrosion Resistance: 904L has superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for aggressive environments such as acidic or chloride-containing fluids.

High Temperature Resistance: 904L maintains its strength and corrosion resistance at elevated temperatures, which is crucial for high-pressure systems in power plants, refineries, and chemical plants.

Durability: Forged steel offers improved mechanical properties compared to cast steel, providing a longer service life under demanding conditions.

Wafer-Type Design for Space and Weight Efficiency

The wafer-type design is particularly advantageous for installations where space and weight are critical. Unlike full-bodied valves, which can be bulky and require additional space, wafer-type valves are thinner and lighter. This design is commonly used in systems where there is a need for reduced installation space, such as compact pipelines and systems with high-density piping layouts.

Compact and Lightweight Construction

The wafer design significantly reduces the overall size and weight of the valve. This feature is beneficial in applications where weight is a concern, such as offshore oil platforms or mobile processing units. The reduced weight also makes handling, installation, and maintenance more efficient and cost-effective.

3. Working Principle of the Wafer Type Lift Check Valve

The working principle of the wafer-type lift check valve is based on its ability to allow flow in one direction while preventing reverse flow. The valve consists of several key components:

Valve Body: The body is typically made from forged steel and serves as the main structure of the valve.

Disc: The disc is a movable element that lifts and falls based on the pressure differential.

Spring (Optional): Some lift check valves include a spring that assists in closing the disc when the flow stops or reverses.

When the flow pressure is higher than the pressure on the opposite side of the disc, the disc is pushed upward, allowing the fluid to pass through. If the flow stops or reverses, the disc is pushed back into its seat, sealing the valve and preventing backflow. This process ensures a reliable seal without the risk of leakage during reverse flow.

4. Applications of the API 594 Forged Steel 904L Wafer Type Lift Check Valve

Due to its robust design and material properties, the API 594 Forged Steel 904L Wafer Type Lift Check Valve is suitable for a variety of demanding industrial applications. Some of the key sectors where these valves are used include:

Oil and Gas: In oil refineries, petrochemical plants, and offshore platforms, where high resistance to corrosion and high temperature is essential.

Power Generation: In steam and water systems, where the valve prevents reverse flow in cooling water circuits and maintains system integrity.

Chemical Processing: For handling corrosive chemicals, where the 904L alloy ensures resistance to acids and other aggressive fluids.

Water Treatment: In municipal water supply systems, where the valve is used to prevent backflow in pipelines and ensure one-way flow of water.

Marine and Offshore: Due to the valve’s resistance to seawater corrosion, it is also commonly used in marine and offshore oil and gas applications.

5. Advantages of the API 594 Forged Steel 904L Wafer Type Lift Check Valve

Corrosion Resistance: The 904L stainless steel construction provides exceptional corrosion resistance, especially in harsh chemical and marine environments.

Compact Design: The wafer-type design is space-saving and lightweight, making it ideal for installations where space is at a premium.

High Performance: The lift check mechanism provides reliable backflow prevention with minimal pressure loss and low maintenance.

Durability: The forged steel body and 904L material ensure long-lasting performance even in high-pressure and high-temperature conditions.

Cost-Effective: The reduced weight and size of the wafer valve lead to lower installation costs and ease of maintenance.

6. Limitations of the API 594 Forged Steel 904L Wafer Type Lift Check Valve

Flow Resistance: While the lift check valve operates efficiently, it may still create some flow resistance compared to other valve types, such as dual plate or ball check valves.

Size Constraints: Due to the wafer design, the valve may not be suitable for very large-diameter pipelines where more robust check valve solutions are needed.

Potential for Water Hammer: Although the lift check valve is designed to prevent backflow, if the disc closes too abruptly, it could contribute to water hammer, potentially damaging the system.

The API 594 Forged Steel 904L Wafer Type Lift Check Valve is an ideal solution for applications that require reliable backflow prevention, particularly in systems exposed to harsh environments. With its corrosion-resistant 904L stainless steel construction, compact wafer-type design, and high-performance lift mechanism, this valve offers several advantages, including durability, space-saving installation, and efficient operation in high-pressure and high-temperature conditions.

By adhering to the stringent requirements outlined in API 594, this valve ensures that it meets the rigorous demands of industries such as oil and gas, chemical processing, and power generation. Although it may not be suitable for all types of fluid systems due to its inherent limitations, the 904L wafer-type lift check valve remains a preferred choice in many industrial settings for preventing backflow and maintaining system integrity.