0102030405

PRESSURE SEALED VALVES

What are Pressure Sealed Valves?

Pressure sealed valves are a type of valve specifically designed to handle high-pressure environments. These valves are engineered with a sealing mechanism that ensures the valve body remains tightly sealed under pressure. Unlike standard valves, which rely on mechanical fasteners or gaskets to form a seal, pressure sealed valves utilize the pressure of the fluid or gas itself to maintain the integrity of the seal. As the pressure within the system increases, the sealing mechanism becomes tighter, preventing leaks even in extreme conditions.

Pressure sealed valves are commonly found in industries such as oil and gas, chemical processing, power generation, and water treatment, where high-pressure systems are the norm.

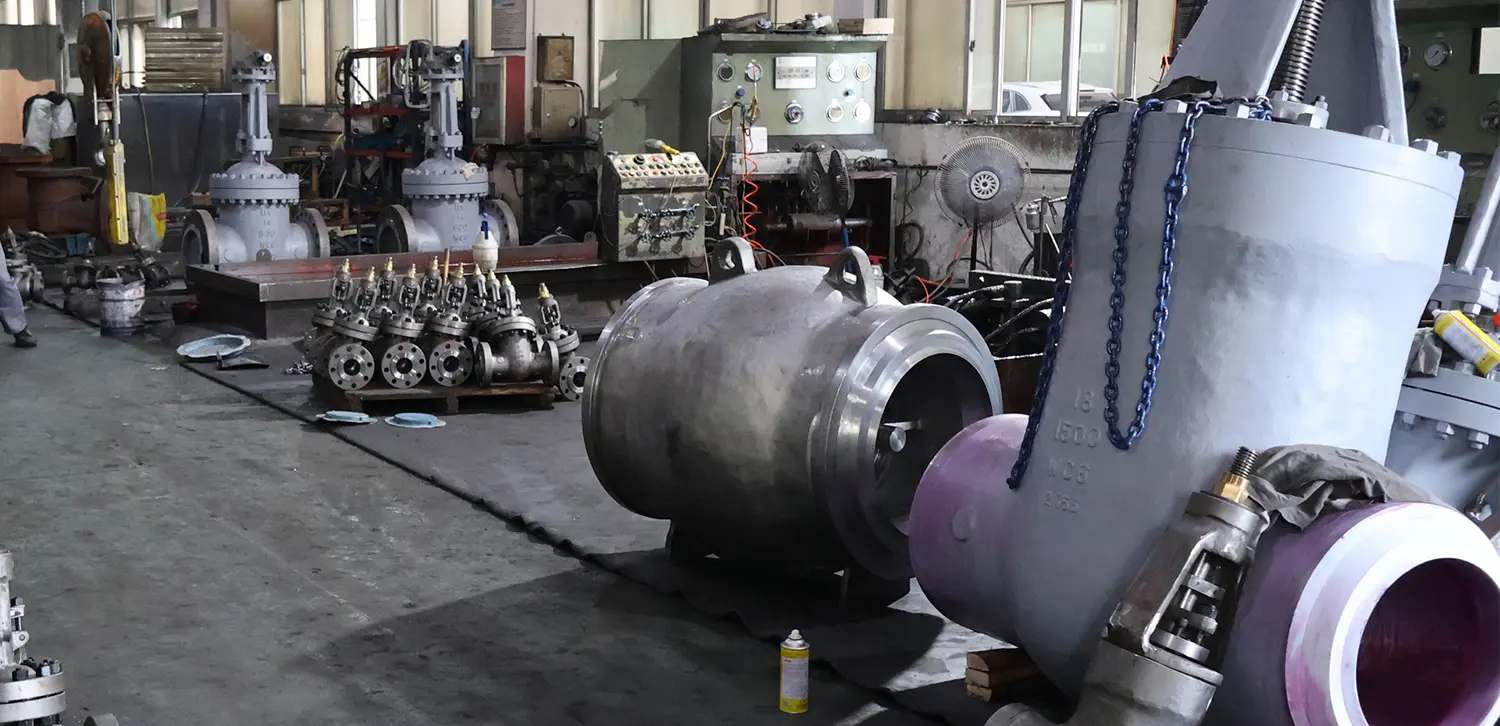

Types of Pressure Sealed Valves

Pressure sealed valves come in various types, each suited to specific applications depending on factors such as fluid type, pressure range, and system requirements. Below are the most common types:

Gate Valves: Used primarily for on/off control, gate valves are designed for full flow with minimal resistance. They are commonly employed in high-pressure applications where sealing is critical, such as in oil and gas pipelines.

Globe Valves: Globe valves are ideal for regulating flow. Their design allows for fine control of flow rates, making them suitable for pressure-sensitive applications like steam systems in power plants.

Check Valves: These valves prevent backflow in a system, which is crucial in high-pressure pipelines. They ensure that fluid only flows in one direction, protecting equipment from pressure surges.

Each type of pressure sealed valve is engineered for specific functions, ensuring system integrity under varying pressure conditions.

Function of Pressure Sealed Valves

The primary function of a pressure sealed valve is to control the flow of fluids or gases while maintaining a secure seal, even in high-pressure systems. These valves regulate the flow by opening or closing a passage through which the fluid or gas flows. When closed, the valve completely blocks the flow, and when open, it allows the fluid or gas to pass through.

One of the most critical aspects of pressure sealed valves is their ability to withstand high-pressure environments without compromising the system’s integrity. This capability is vital in preventing leaks, which could lead to catastrophic failures, safety hazards, or environmental contamination.

Design of Pressure Sealed Valves

Pressure sealed valves are typically designed with a few key features that differentiate them from standard valves:

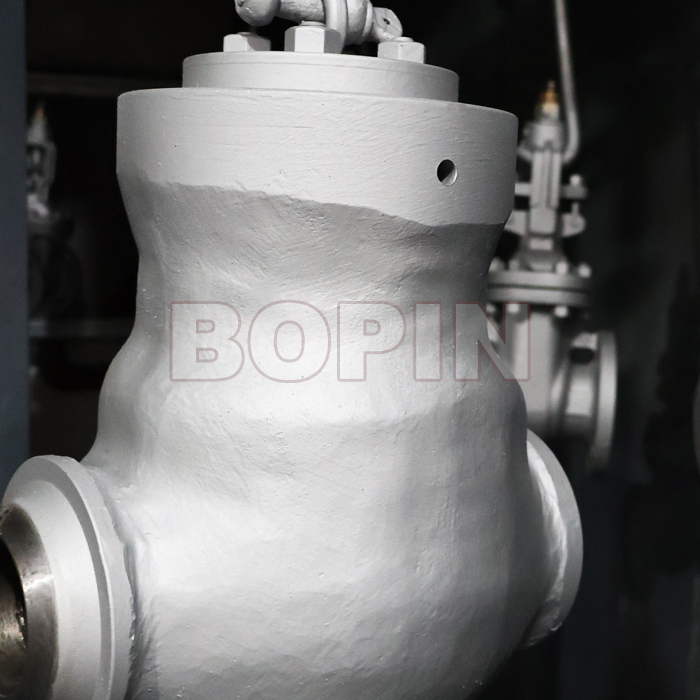

Pressure-Activated Sealing Mechanism: The most distinctive feature of pressure sealed valves is their sealing mechanism. The valve body is designed in such a way that, when the internal pressure increases, it forces the valve body to seal more tightly. This design ensures that even if the external environment is subjected to extreme pressure, the seal remains intact.

Reinforced Body: To withstand high-pressure conditions, pressure sealed valves are constructed from materials such as forged steel, stainless steel, or other durable alloys. These materials are chosen for their strength, durability, and resistance to corrosion, making them ideal for handling aggressive fluids or gases.

Precision Machining: The internal components of pressure sealed valves are often machined to very tight tolerances. This ensures that there are no gaps or inconsistencies in the sealing surfaces, further enhancing the valve’s ability to withstand pressure and maintain a secure seal.

Self-Sealing Action: Pressure sealed valves rely on the internal pressure to provide a self-sealing action. As the pressure increases within the valve, the seal becomes more effective, reducing the likelihood of leaks. This feature makes pressure sealed valves particularly useful in applications where manual sealing or additional sealing devices may not be feasible.

Minimal External Seals: Unlike traditional valves, which rely on gaskets or other external seals, pressure sealed valves minimize the use of external seals. This design reduces the risk of leaks due to seal degradation, which is common in traditional valve designs.

Applications of Pressure Sealed Valves

Pressure sealed valves are used in various industries that require high-pressure systems, including:

Oil and Gas: In the oil and gas industry, pressure sealed valves are commonly used in pipeline systems, drilling operations, and refineries. These valves are essential for maintaining the integrity of pipelines that carry oil, natural gas, and other hazardous substances under high pressure. The valves are also used in offshore platforms, where the pressure and corrosive nature of the environment demand highly reliable sealing mechanisms.

Chemical Processing: Chemical plants often deal with corrosive, volatile, or high-pressure fluids. Pressure sealed valves are crucial in these settings to prevent leaks, maintain safe operations, and ensure that chemicals are contained within the system. They are used in reactors, distillation columns, and pipelines to handle fluids under varying pressures.

Power Generation: In power plants, pressure sealed valves are used to control steam, water, and other fluids within the plant’s high-pressure systems. These valves help regulate the flow of steam to turbines, cooling systems, and boilers, ensuring the safe and efficient generation of power.

Water Treatment: Pressure sealed valves are also employed in water treatment plants, where they are used to control the flow of water under high-pressure conditions. These valves ensure that the flow of water through filtration systems, pipelines, and pumps remains consistent and free from leaks.

Marine and Subsea Applications: In subsea oil and gas exploration, where pressure can be extremely high, pressure sealed valves are essential for preventing leaks in underwater pipelines and equipment. These valves are designed to withstand the harsh conditions of the deep sea, including high pressures and corrosive saltwater.

Benefits of Pressure Sealed Valves

Pressure sealed valves offer several key advantages over traditional valve designs, including:

Leak Prevention: The primary benefit of pressure sealed valves is their ability to prevent leaks, even in high-pressure systems. The self-sealing action ensures that the valve remains secure under extreme conditions, which is critical for safety and system reliability.

Durability: Due to their reinforced construction and pressure-activated sealing mechanisms, pressure sealed valves are highly durable and can withstand harsh environments, including extreme temperatures, corrosive fluids, and high-pressure conditions.

Reduced Maintenance: Because pressure sealed valves minimize the use of external seals, there is less wear and tear on sealing components, reducing the frequency of maintenance and the potential for failures.

Enhanced Safety: In industries such as oil and gas, chemical processing, and power generation, the safety of personnel and the environment is of utmost importance. Pressure sealed valves help mitigate the risk of hazardous leaks and spills, thereby enhancing overall safety.

Cost-Effectiveness: While pressure sealed valves may have a higher upfront cost compared to traditional valves, their durability and reduced need for maintenance can lead to long-term cost savings. This makes them a cost-effective solution in the long run, especially for critical applications.