0102030405

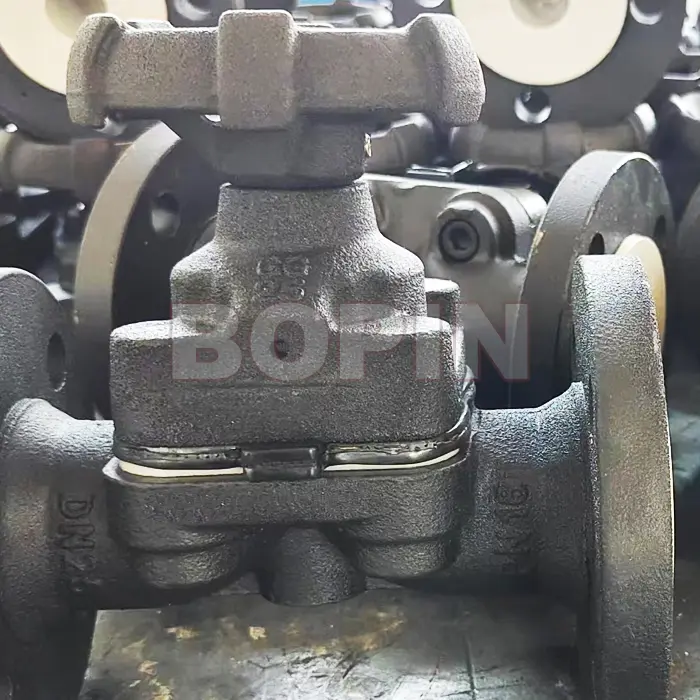

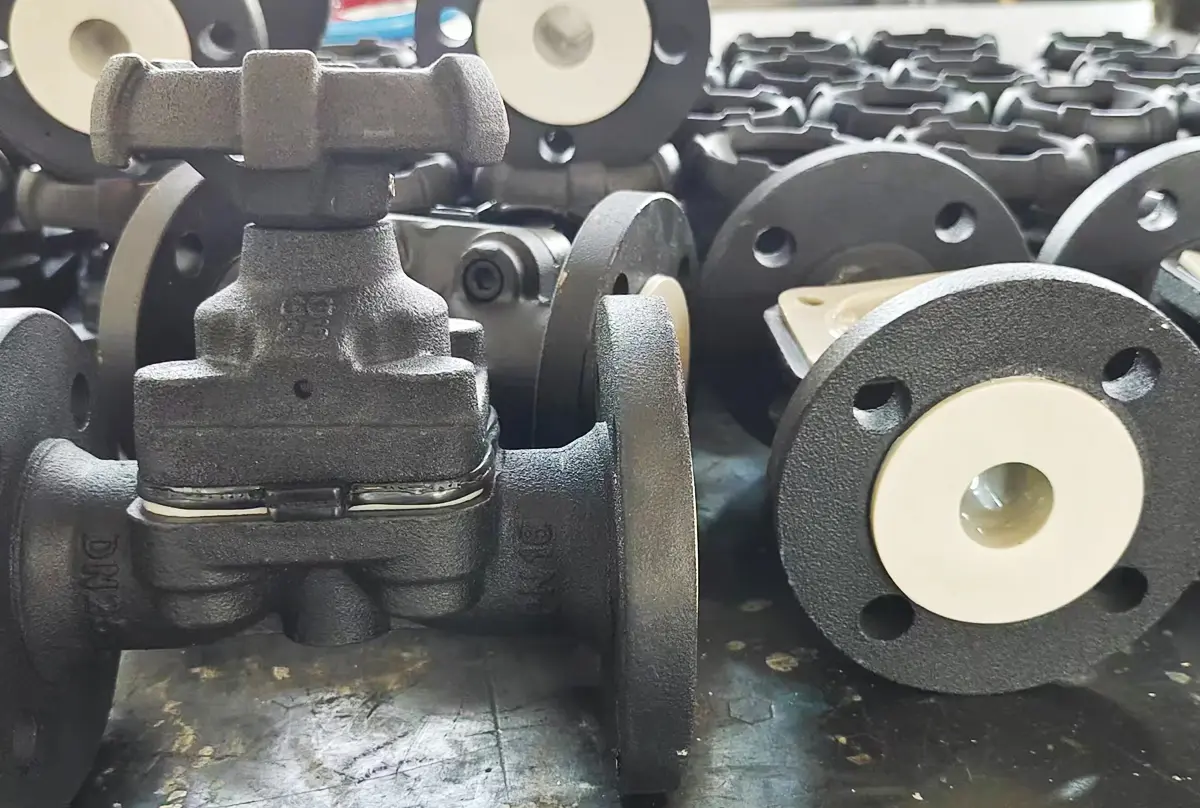

PFA LINED DIAPHRAGM VALVE

Advantages & Disadvantages of Performance of Diaphragm Valve

The structural form of diaphragm valve is very different from that of general valves. It is a new type of valve and a special form of shut-off valve. Its opening and closing member is a diaphragm made of soft material, which separates the valve body cavity from the valve cover cavity and driving components. It is now widely used in various fields. The commonly used diaphragm valves include rubber lined diaphragm valves, fluorine lined diaphragm valves, unlined diaphragm valves, and plastic diaphragm valves. Diaphragm valves use corrosion-resistant lined valve bodies and corrosion-resistant diaphragms instead of valve core components, utilizing the movement of the diaphragm for regulating purposes. The valve body material of the diaphragm valve is made of cast iron, cast steel, or cast stainless steel, and lined with various corrosion-resistant or wear-resistant materials, diaphragm material rubber, and polytetrafluoroethylene. The lining diaphragm has strong corrosion resistance and is suitable for regulating highly corrosive media such as strong acids and alkalis.

The Principle of Diaphragm Valve

1. There is no contact between the mechanical operation part and the medium.

2. When the internal shape is not fully open, the flowability of the medium is not optimal.

3. The sealing structure ensures that there are no dead corners.

Advantage of Diaphragm Valve

1. Diaphragm valves have a simple structure, low fluid resistance, and greater flow capacity compared to other types of valves of the same specifications;

2. Suitable for corrosive, viscous, and slurry media.

3. The valve is easy to disassemble and repair quickly, and the replacement of the diaphragm can be completed on-site and in a short period of time.

4. No leakage, can be used for regulating high viscosity and suspended particle media. The diaphragm isolates the medium from the upper chamber of the valve stem, so there is no packing medium and it will not leak out.

The flow characteristics of diaphragm valves are close to fast opening characteristics, approximately linear before 60% stroke, and there is little change in flow after 60%.

6. Pneumatic diaphragm valves can also be equipped with feedback signals, limiters, and locators to meet the needs of self-control, program control, or flow regulation.

7. The feedback signal of the pneumatic diaphragm valve adopts non-contact sensing technology. This product uses a thin film propulsion cylinder instead of a piston cylinder, eliminating the disadvantage of the piston ring being easily damaged, causing leakage and preventing the valve from opening and closing. When the gas source malfunctions, the handwheel can still be operated to open and close the valve.

When used urgently in China, there are stocks and accessories available in small quantities.

Disadvantage

1. Cannot be used in high-pressure situations.

2. Due to the limitations of diaphragm and lining materials, the pressure resistance and temperature resistance are poor, and it is generally only suitable for nominal pressures of 1.6 MPa and below 150 ° C.

Application Area

Suitable for corrosive and inert media such as chemical industry, water treatment industry, water purification workshop, food industry, printing and dyeing industry, paper industry, and any field with extremely harsh conditions and high chemical anti-corrosion requirements for valve sealing performance. Typical application processes include power plants, chemical industry, steel refining, paper making, metallurgy, pharmaceuticals, food, electronics, etc.

Diaphragm Valve Selection

Valves can be applied in a wide range of industrial fields. The chemical and physical properties of working media have a direct impact on the material selection of valve components In addition, the requirements of mechanical characteristics and process characteristics determine the application scope of the valve, in order to meet the requirements of different operating situations We provide users with valve materials and connection methods The following types of valves are available for actuator selection

- Ductile iron lining PP

Suitable for acid, wastewater, and saltwater Make good use of surface treatment in water treatment Pickling and electroplating of food and industrial water can resist 30-33% HCL or 50% NAOHPFA, suitable for -20 to 250T/-30 to 120 ° C

- Ductile iron with ceramic lining

Ceramics have excellent corrosion resistance and can resist the corrosion of various strong acids, alkalis, and other chemical substances. Therefore, they are suitable for various highly corrosive occasions and have good wear resistance, making them suitable for use in conditions with barley grains. Suitable for working under high temperature conditions

- Ductile iron lined with PFA

Mineral acids Oxidized acids and inorganic acids Has a certain degree of functional decay towards basic substances: halogens Metal salts Organic acid spherical compounds Alcohol and acetaldehyde Ketones And nitrogen water: PFA is more stable than other lining materials at high temperatures Suitable for -30- to 150 ° C

Selection of Diaphragm Material

- Ethylene propylene rubber (EPDM)

Used for acid, wastewater, and saltwater Make good use of surface treatment in water treatment Pickling and electroplating of food and industrial water can resist 30-33% HCL or 50% NAOHPFA. The temperature range is -30 to 130 ° C.

- EPDM/PFA or EPDM/PTFE

Mineral acids Oxidized acids and inorganic acids Has a certain degree of functional decay towards basic substances: halogens Metal salts Organic acid spherical compounds Alcohol and acetaldehyde Ketones And nitrogen water: PFA is more stable than other lining materials at high temperatures. Suitable for -30 to 150 ° C