0102030405

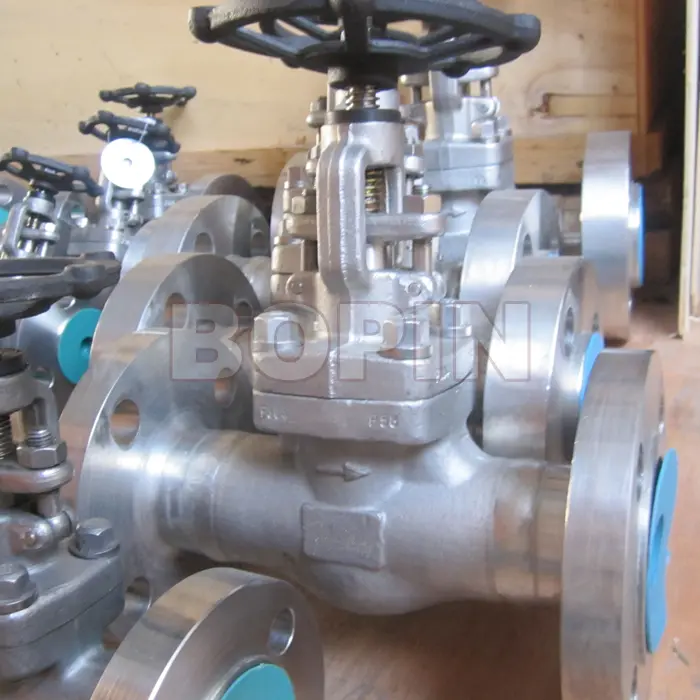

Forged Steel Globe Valves

Key Features

Forged steel globe valves are made from high-quality steel that is subjected to the forging process. This enhances the material’s grain structure, making the valve stronger and more resistant to pressure, fatigue, and wear. It also provides better integrity and reliability, especially in high-pressure and high-temperature environments.

Flow Control:

Globe valves are designed for regulating flow rather than just stopping or starting it. The valve has a movable plug or disc that is positioned inside the body to constrict or allow flow through the passageway. This allows operators to adjust the flow rate precisely, making them ideal for throttling applications.

Body Design:

The body of a forged steel globe valve is typically spherical in shape, with the flow path running in a straight line through the valve. The design of the valve body and internal parts is intended to minimize turbulence, allowing for smoother regulation of the flow.

Pressure and Temperature Handling:

Production Range

The production range of forged steel globe valves varies widely to meet the needs of diverse industries and applications. These valves are manufactured in a range of sizes, pressure classes, materials, and design configurations, allowing them to handle a variety of fluid control needs, from low-pressure systems to extreme high-pressure and high-temperature environments.

1. Sizes

Standard Sizes: Forged steel globe valves are typically available in sizes ranging from ½ inch (DN 15) to 2 inches (DN 50), though larger sizes can be produced based on specific requirements.

Custom Sizes: Some manufacturers may produce valves outside of the standard size range, including custom sizes for specialized applications, such as large-scale industrial systems or offshore platforms.

2. Pressure Classes

Forged steel globe valves are available in various pressure classes, each designed to withstand specific pressure ranges. The most common pressure ratings include:

Class 150 (PN 20): Suitable for low to medium-pressure systems.

Class 300 (PN 50): Used for moderate to high-pressure applications.

Class 600 (PN 100): Common for higher pressure systems in industrial processes.

Class 900 (PN 150), Class 1500 (PN 250): Designed for very high-pressure applications, such as steam systems and heavy-duty industrial processes.

Class 2500 (PN 420): For extreme high-pressure environments, such as oil and gas pipelines and pressure vessels.

3. Material Types

Carbon Steel: The most commonly used material for standard applications. Examples include ASTM A105 and A350 LF2.

Alloy Steel: Used for higher strength and heat resistance, with materials like ASTM A182 F11, F22, and F91 commonly used in power generation or high-temperature applications.

Stainless Steel: Ideal for corrosive environments or where superior corrosion resistance is required, such as in chemical processing or marine industries. Common materials include ASTM A182 F304, F316, and F304L.

Special Alloys: For extreme conditions such as high temperature or highly corrosive environments, alloys like Inconel, Monel, or Hastelloy can be used.

4. Design Types

Y-Pattern Globe Valve: A specific design where the body of the valve is shaped like the letter "Y", providing a more direct flow path and reducing turbulence, which can be advantageous for flow regulation in high-pressure systems.

Angle Pattern: Similar to the Y-pattern, but with an angle design (usually 45°) to help with better flow characteristics in specific installations.

5. End Connections

Flanged Ends: The most common connection type, particularly for larger valves. Forged steel globe valves with flanged ends are easy to install and provide a secure, leak-tight connection.

Butt-Weld Ends: Often used for seamless piping systems and when reduced weight or a more compact installation is required.

Socket-Weld Ends: Typically used for smaller valve sizes in high-pressure systems where compactness and integrity are important.

Threaded Ends: Common in smaller sizes, typically for applications with lower pressure or where ease of installation and removal is required.

Application

Forged steel globe valves are integral components in various industries, providing precise flow control and isolation in critical systems. Their robust construction and versatility make them suitable for a wide range of applications:

1. Power Generation: In power plants, forged steel globe valves are essential for regulating steam and water flow within boilers, turbines, and cooling systems. Their ability to withstand high pressures and temperatures ensures efficient energy production.

2. Chemical Processing: The chemical industry utilizes forged steel globe valves to manage the flow of various chemicals, including corrosive substances like nitric acid and acetic acid. Their resistance to corrosion and high temperatures makes them ideal for maintaining safety and efficiency in chemical plants.

3. Oil and Gas Industry: Forged steel globe valves are employed in the transportation and processing of oil and gas, effectively controlling the flow of hydrocarbons under high-pressure conditions. Their durability ensures reliable operation in demanding environments.

4. Water Treatment Facilities: In water and wastewater treatment plants, these valves regulate the flow of water through filtration and treatment processes. Their precise control capabilities are crucial for maintaining water quality standards.

5. Pharmaceutical Manufacturing: The pharmaceutical industry relies on forged steel globe valves to control the flow of various media in the production of medicines and bio-products. Their sanitary design and resistance to corrosion are vital for maintaining product integrity.

6. Petrochemical Refineries: Forged steel globe valves are used to control the flow of fluids in refining processes, including the handling of crude oil and refined products. Their ability to operate under high pressures and temperatures ensures the safe and efficient processing of petrochemical materials.

7. HVAC Systems: In heating, ventilation, and air conditioning systems, these valves regulate the flow of steam and water, contributing to energy efficiency and comfort in large buildings and industrial facilities.

8. Cryogenic Applications: Forged steel globe valves are suitable for cryogenic applications, such as liquefied natural gas (LNG) processing, due to their ability to operate at extremely low temperatures.

The selection of forged steel globe valves for these applications is driven by their durability, precise flow control, and ability to withstand extreme operating conditions, ensuring safety and efficiency across various industries.