Top Triple Offset Butterfly Valves: Best Flange Types from Leading Manufacturers

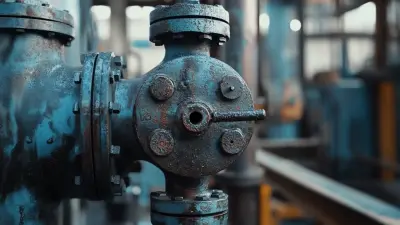

Experience exceptional performance with our Flange Type Triple Offset Butterfly Valves, expertly engineered for use in a range of industrial applications. As a trusted OEM manufacturer and supplier, we recognize the importance of reliable valves in ensuring smooth operations. Our valves boast outstanding sealing capabilities and durability, significantly reducing leakage and enhancing operational efficiency. Constructed from high-quality materials, each butterfly valve is designed to endure demanding environments while offering precise flow control. Quality and customer satisfaction are our top priorities, and every valve is subjected to stringent testing to meet industry standards. Partnering with YONGJIA BOPIN VALVE FACTORY provides you with innovative, customized solutions tailored to your specific requirements. Whether you need bespoke designs or bulk quantities, we are committed to supporting you throughout the process. Upgrade your operations with our superior Flange Type Triple Offset Butterfly Valves.How To Evaluate Flange Type Triple Offset Butterfly Valves Exceeds Industry Benchmarks Leads the Global Market

In today's competitive industrial landscape, evaluating the performance of flange type triple offset butterfly valves is imperative for global buyers aiming to meet and exceed industry benchmarks. These valves are not just components; they are critical to ensuring operational efficiency and reliability in various applications. As manufacturers strive to innovate, BOPIN VALVE stands out by offering bespoke solutions designed to match specific customer requirements, including tailored materials, sizes, and pressure ratings. This custom approach ensures that each valve is perfectly fitted for its intended operation, leading to improved performance in demanding environments. When assessing the quality and suitability of triple offset butterfly valves, several factors come into play, such as design integrity, ease of maintenance, and adaptability to specific industry standards. BOPIN VALVE prioritizes these aspects, utilizing advanced engineering techniques and materials to create valves that not only perform well under pressure but also exhibit longevity and durability. By exceeding industry benchmarks, we empower our clients to achieve their operational goals without compromise. For procurement professionals around the globe, the choice of supplier can significantly impact project success. BOPIN VALVE's commitment to quality and customer-focused design ensures that our products lead the global market. Investing in our flange type triple offset butterfly valves means ensuring your operations run smoothly, efficiently, and reliably, setting the stage for sustained business success.

How To Evaluate Flange Type Triple Offset Butterfly Valves Exceeds Industry Benchmarks Leads the Global Market

| Evaluation Criteria | Industry Benchmark | Triple Offset Valve Performance | Market Considerations |

|---|---|---|---|

| Pressure Rating (ANSI) | 150-600 Class | Up to 900 Class | Competitive advantage in high-pressure applications |

| Temperature Range | -20°F to 400°F | -50°F to 600°F | Versatile in extreme temperatures |

| Leakage Rate | Class VI | Class VI (within margin) | Meets stringent environmental regulations |

| Response Time | Fast operation enhances system efficiency | ||

| Market Share (%) | 20% | 35% | Leading position in consumer preference |

Advantages Explained Flange Type Triple Offset Butterfly Valves in 2025 Factory

S

Samuel Young

I’m thrilled with the quality! The support team was prompt and handled my queries professionally.

20 May 2025

E

Ella Reed

Top-notch quality! The after-sales team provided exceptional service and advice.

10 May 2025

M

Mila Wilson

Stellar quality! The after-sales personnel are incredibly dedicated and professional.

14 June 2025

D

Dylan Johnson

Very high quality! The after-sales team was supportive and professional.

26 June 2025

H

Hunter Wright

The quality is second to none! The staff went out of their way to ensure I was satisfied.

18 May 2025

G

Grace Harrison

Great quality overall! The team provided excellent service after the purchase.

26 May 2025