DIN LIFT TYPE CHECK VALVE MANUFACTURER

1. Introduction

2. Design Standards and Compliance

Key design codes and reference standards include:

|

Design standard

|

DIN EN 12334 / DIN 3356

|

|

Flange connection

|

DIN EN 1092-1 (PN 10, PN 16, PN 25, PN 40)

|

|

Face-to-face dimensions

|

DIN EN 558

|

|

Testing standard

|

DIN EN 12266-1 (hydrostatic and seat leakage tests)

|

|

Inspection

|

EN 10204 3.1 or 3.2 certification available upon request

|

3. Material Specifications

|

Component

|

Material Options (Typical DIN Grades)

|

Remarks

|

|

Body

|

GS-C25 (1.0619), A216 WCB, GGG40, Stainless Steel (1.4408)

|

Carbon or stainless steel for general and corrosive service

|

|

Disc

|

1.4021, 1.4404, 1.4301

|

Hard-faced or stainless steel for corrosion and wear resistance

|

|

Seat

|

Stellite, 13Cr, 316

|

Hard-faced for long service life

|

|

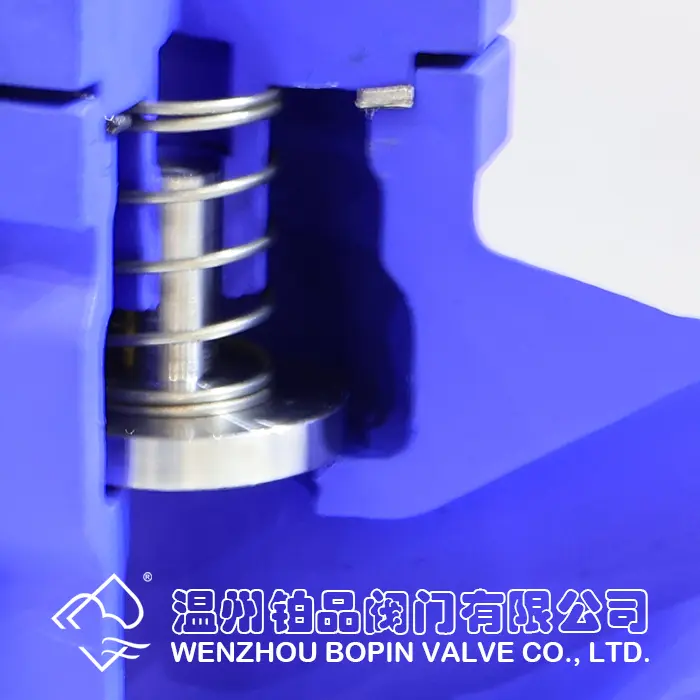

Spring

|

1.4310, Inconel X-750

|

Ensures prompt closure under backflow

|

|

Bonnet

|

Same as body

|

Bolted or welded construction

|

|

Gasket

|

Graphite, PTFE, or spiral wound

|

For tight sealing between body and bonnet

|

|

Guide / Stem

|

Stainless steel

|

Provides stable disc movement

|

4. Working Principle

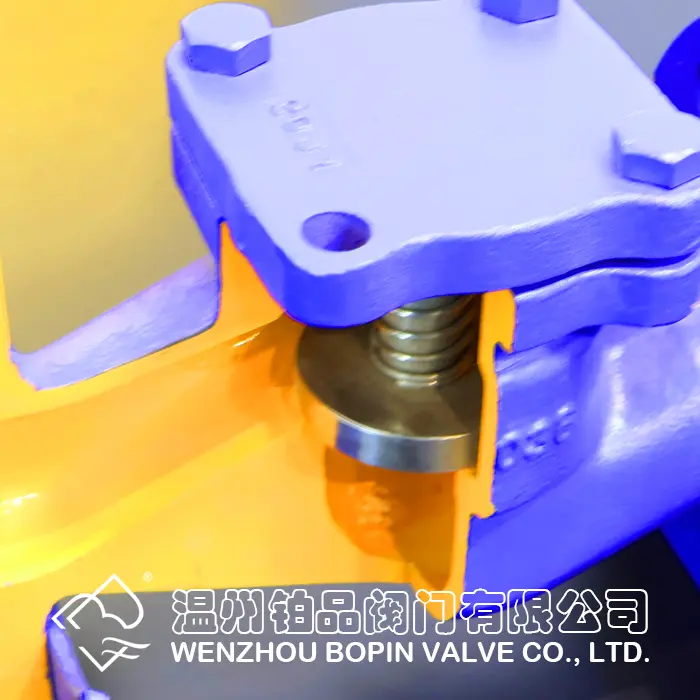

The spring-loaded lift type check valve operates automatically under flow pressure without external actuation. When fluid flows in the correct direction (forward flow), the pressure of the fluid lifts the disc off the seat, allowing flow through the valve body. The compression spring is temporarily compressed during this process.

When the flow rate decreases or reverses, the spring force and reverse pressure act together to push the disc back onto the seat, closing the valve instantly. This rapid response prevents water hammer, backflow, and pressure surges in the system.

This axial lift motion design provides:

Quick closure response due to the preloaded spring

Leak-tight sealing when backflow occurs

Reduced seat wear because of linear movement

Compact body structure compared to swing check valves

For horizontal installations, the valve is generally designed with a vertical lift axis and guide to ensure stable operation. In vertical pipelines (upward flow), the valve naturally aligns with the flow direction, allowing smooth disc movement.

5.Features and Advantages

Compact and Robust Design

The lift-type configuration occupies less space than swing check valves and provides higher structural strength. The short disc travel reduces mechanical stress and ensures long-term reliability.

Spring-Loaded Mechanism

The integrated spring enables faster closing action, minimizing backflow duration and water hammer risk. It is particularly suitable for high-pressure and high-speed flow systems.

Tight Sealing Performance

Precision-machined sealing surfaces and optional metal-to-metal or soft-seat configurations ensure leak-free performance under all rated conditions.

Maintenance-Friendly Construction

The bolted bonnet design allows easy disassembly and inspection. Seat and disc components can be replaced or refurbished without removing the entire valve from the pipeline.

Versatile Installation

Applicable for both horizontal and vertical upward flow pipelines. The design adapts to varied piping layouts while maintaining optimal flow characteristics.

Standardized Connections

DIN flange ends ensure compatibility with European piping systems. Standard pressure ratings (PN10–PN40) allow flexible system integration.

Long Service Life

High-quality materials, corrosion-resistant internals, and durable springs contribute to a long operational lifespan, even under demanding service conditions.

6. Typical Applications

7. Testing and Quality Assurance

Each valve undergoes hydrostatic shell and seat leak tests per EN 12266-1 to ensure performance integrity. Dimensional and visual inspections verify compliance with DIN specifications, and non-destructive testing (NDT) may be conducted upon request. Quality control documentation such as EN 10204 3.1 material certificates, pressure test reports, and