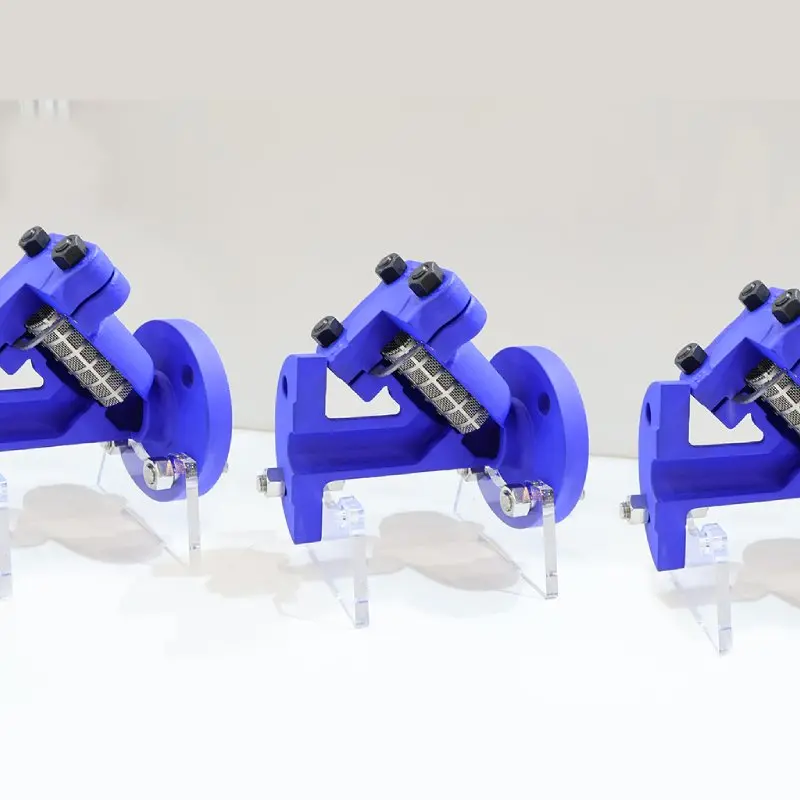

DIN GS-C25 Y TYPE STRAINER FOR STEAM SYSTEM

1. Overview of DIN GS-C25 Flange End Y Type Strainer for Steam System

2. Design and Construction

Key design features include:

Body Material: GS-C25 (DIN 17245 or equivalent ASTM A216 WCB)

A cast carbon steel material offering excellent mechanical strength and resistance to thermal stress. It performs well in high-pressure and high-temperature environments typical of steam service.

Screen Element: Stainless steel perforated or mesh screen (AISI 304 / 316)

The filter element provides precise particle retention while resisting corrosion from condensate or minor chemical impurities. Mesh size is customizable according to process requirements, typically ranging from 0.5 mm to 3 mm perforation or 20–100 mesh for fine filtration.

Flanged Ends:

Compliant with DIN EN 1092-1 flange standards, typically rated PN16, PN25, or PN40. These flanged ends provide secure and leak-free connections, simplifying installation and maintenance.

Cover and Gasket:

The blow-off cover (or screen cover) is bolted and sealed using a graphite or spiral-wound stainless-steel gasket, ensuring tight sealing under high temperature and steam pressure conditions.

Drain Plug / Blow-off Connection:

A threaded or flanged blow-off port allows for flushing or cleaning without removing the strainer from the line. For steam systems, a blow-off valve can be installed to periodically discharge debris under pressure.

3. Working Principle

The DIN GS-C25 Flange End Y Type Strainer operates on a simple yet effective principle of mechanical filtration. As steam or condensate enters the strainer body, the medium flows through the stainless steel screen. Solid particles and impurities are trapped on the inner surface of the screen while the clean medium passes downstream.

Over time, debris accumulates in the strainer’s “Y” leg — the lower branch of the body — which can be drained or flushed out through the blow-off connection. Regular cleaning ensures continuous performance and prevents pressure drop across the strainer.

This mechanism protects steam equipment from wear, erosion, and blockages, thus prolonging operational life and maintaining system efficiency.

4. Technical Specifications

|

Parameter

|

Specification

|

|

Design Standard

|

DIN / EN 12516 / EN 558

|

|

Connection Type

|

Flanged Ends (DIN EN 1092-1)

|

|

Pressure Rating

|

PN16 / PN25 / PN40

|

|

Body Material

|

GS-C25 Carbon Steel

|

|

Screen Material

|

Stainless Steel AISI 304 / 316

|

|

Screen Mesh

|

0.5 mm – 3.0 mm perforated, or 20–100 mesh

|

|

Cover Gasket

|

Graphite / Spiral Wound SS + Graphite

|

|

Drain Plug

|

Carbon Steel or Stainless Steel

|

|

Working Medium

|

Steam, Condensate, Water, Oil, Gas

|

|

Temperature Range

|

–10°C to +450°C

|

|

Flow Direction

|

Indicated by arrow on body

|

|

Installation Position

|

Horizontal or vertical (flow downward)

|

5. Application in Steam Systems

In steam systems, purity of the steam and condensate is crucial for ensuring efficiency and preventing damage to control valves, steam traps, and turbines. The GS-C25 Y Type Strainer plays an essential role at various points in the steam distribution network:

Upstream of Control Valves: Protects valve seats and internals from particles that can cause erosion or leakage.

Before Steam Traps: Prevents clogging of steam trap orifices, ensuring proper condensate discharge.

At Pressure Reducing Stations: Guards sensitive regulators and pilot valves from impurities.

Ahead of Flow Meters: Maintains measurement accuracy by avoiding mechanical obstruction or fouling of sensors.

Its high-temperature resistance and robust carbon steel body make it well-suited for superheated and saturated steam lines. The ability to install the strainer in either horizontal or vertical orientation provides flexibility during system design and layout.

6. Advantages

Durable Construction:

The GS-C25 carbon steel body withstands high thermal and pressure stresses commonly encountered in industrial steam applications.

Efficient Filtration:

Stainless steel screen provides long service life, excellent corrosion resistance, and consistent filtration performance.

Low Pressure Drop:

The Y-shaped flow path minimizes turbulence and pressure loss, optimizing steam system efficiency.

Easy Maintenance:

Quick removal of the screen cover allows for fast cleaning or replacement. The blow-off connection enables flushing without dismantling.

Flexible Installation:

Can be installed in horizontal or vertical positions depending on pipeline layout and space availability.

Cost-Effective Protection:

By preventing wear and fouling in downstream equipment, the Y strainer significantly reduces maintenance costs and downtime.

Standardized Design:

Fully compliant with DIN standards, ensuring compatibility with European and international pipeline systems.

7. Installation and Maintenance

Proper installation and maintenance are key to reliable performance and extended service life of the Y type strainer.

Installation Guidelines:

Ensure the arrow cast on the strainer body aligns with the direction of fluid flow.

Install the strainer with the filter cap facing downward to collect debris efficiently.

Provide enough space for removal of the cover and screen during maintenance.

Use suitable gaskets and torque the flange bolts evenly to avoid leakage.

In steam lines, install the strainer ahead of control equipment to protect critical components.

Maintenance Procedures:

Periodically open the cover or blow-off valve to remove accumulated debris.

Clean the screen with a wire brush or compressed air; replace if damaged.

Inspect gaskets for wear and replace as needed.

After reassembly, gradually re-pressurize the line to prevent thermal shock.

Routine inspection ensures stable flow and protects system components from unfiltered contaminants.

8. Material and Design Advantages of GS-C25

GS-C25, according to DIN 17245, is a high-quality cast carbon steel known for its combination of mechanical strength, toughness, and weldability. It maintains integrity under fluctuating temperatures and pressures typical of steam systems.

Mechanical properties:

Tensile Strength: approx. 410–530 MPa

Yield Strength: approx. 250 MPa

Elongation: 22% minimum

Hardness: 140–190 HB

Performance Benefits:

Excellent resistance to scaling and oxidation at elevated temperatures.

Good machinability for precise flange and thread connections.

Superior impact resistance compared to cast iron.

These characteristics make GS-C25 a preferred choice for valves, strainers, and fittings used in steam and high-pressure water applications.

9. Quality Assurance and Standards

The DIN GS-C25 Flange End Y Type Strainer is manufactured and tested under strict quality control processes to meet European and international standards:

Design & Manufacturing: DIN EN 12516, EN 558

Inspection & Testing: EN 12266-1 (hydrostatic and seat leakage tests)

Flange Connection: EN 1092-1

Painting & Coating: Heat-resistant epoxy or zinc-phosphate primer for corrosion protection

Each strainer undergoes pressure testing, dimensional inspection, and material verification before delivery. Certificates of compliance and test reports are typically provided upon request.

10. Typical Industries and Applications

Steam Distribution Networks

Thermal Power Plants

Petrochemical and Refining Units

District Heating Systems

Textile and Food Processing Plants

Chemical and Pharmaceutical Facilities

Paper and Pulp Mills

HVAC and Boiler Systems

In all these sectors, maintaining clean, impurity-free steam is vital for operational efficiency, safety, and product quality — roles the Y type strainer fulfills effectively.