+86 19720579616

+86 19720579616

Zalo

Zalo

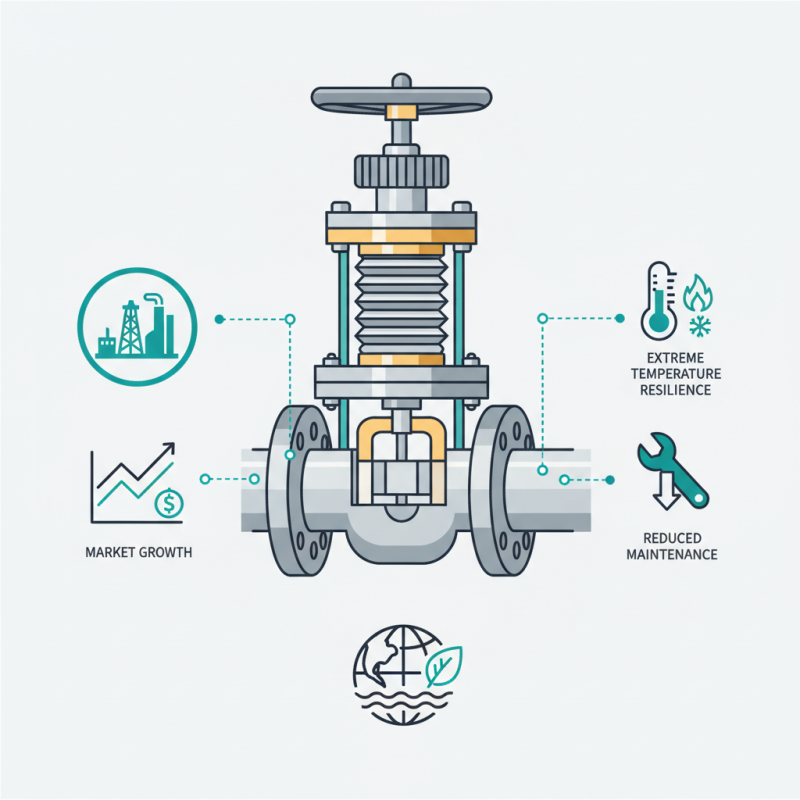

In the rapidly evolving landscape of industrial valves, the demand for reliable and durable products is paramount. API bellows sealed gate valves have emerged as a critical component in various applications, particularly in sectors such as oil and gas, chemical processing, and water management. According to a recent market research report from Grand View Research, the global industrial valve market is projected to reach $105.93 billion by 2025, driven by the increasing investments in infrastructure and the need for efficient fluid control systems. This growth underscores the importance of high-performance valves, with API bellows sealed gate valves standing out for their superior sealing capabilities and minimal leakage potential.

These valves are engineered with a unique bellows design that ensures a tight seal even under extreme pressure and temperature conditions. Industry analysts from Research and Markets highlight that the robust construction and enhanced performance features of API bellows sealed gate valves significantly reduce maintenance costs and downtime, making them a preferred choice for critical applications. As industries continue to prioritize sustainability and operational efficiency, the focus on high-quality valve solutions will only intensify. In this comprehensive overview, we will explore the top API bellows sealed gate valves anticipated for 2025, examining their features, benefits, and the key factors contributing to their reliability and durability in demanding environments.

Bellows sealed gate valves are essential components in various industrial applications, prized for their ability to provide a reliable seal and prevent leakage. These valves employ a flexible bellows design that eliminates the need for external packing, thus reducing wear and tear over time. By effectively isolating the valve stem from the flow media, they minimize the risk of contamination and ensure a safer operational environment. This design not only enhances durability but also helps maintain the integrity of the system by mitigating the potential for leaks, which can lead to costly downtimes and environmental hazards.

When considering the implementation of bellows sealed gate valves in your operations, it's important to focus on specific factors that influence their performance. Selection of the right material is crucial, as it directly affects the valve's chemical compatibility and temperature tolerance. Additionally, proper maintenance and regular inspections can greatly extend the lifespan of these valves.

Tips: Always ensure that the installation is conducted according to the manufacturer’s guidelines, as improper setup can lead to premature failure. Keep an eye on environmental conditions that may affect the valves, especially pressure fluctuations and temperature variations. By adhering to these practices, you can enhance the reliability and efficiency of your valve system.

| Valve Size (Inches) | Pressure Rating (PSI) | Temperature Range (°F) | Material | End Connection | Weight (lbs) |

|---|---|---|---|---|---|

| 2 | 150 | -20 to 250 | Carbon Steel | Flanged | 15 |

| 3 | 300 | 0 to 350 | Stainless Steel | Welded | 25 |

| 4 | 600 | -20 to 450 | Alloy Steel | Flanged | 35 |

| 6 | 150 | -20 to 300 | Carbon Steel | Flanged | 60 |

| 8 | 300 | 0 to 400 | Stainless Steel | Welded | 80 |

When selecting bellows sealed gate valves, several key features set the top models apart and ensure reliable performance and durability. One of the primary benefits of these valves is their exceptional sealing capability. The incorporation of bellows technology significantly reduces the risk of leakage, making them ideal for handling fluids that require stringent containment. This is particularly important in industries such as oil and gas, chemicals, and wastewater treatment, where even minor leaks can lead to substantial environmental and safety hazards.

Another critical feature to consider is the construction material used in these valves. High-quality alloys and corrosion-resistant materials contribute to their longevity and efficacy in challenging environments. Furthermore, these valves often come with enhanced resistance to thermal and pressure fluctuations, ensuring stable operation even under extreme conditions. Their robust design minimizes maintenance needs, providing operators with peace of mind and a lower total cost of ownership. Overall, the right bellows sealed gate valves combine engineering excellence with durability, making them a reliable choice for various industrial applications.

Bellows sealed gate valves have emerged as a crucial component in various industrial applications, offering notable benefits that enhance reliability and durability. These valves are designed to prevent leakage, which is especially critical in environments dealing with hazardous fluids and gases. According to a report by ResearchAndMarkets, the global gate valve market is projected to reach approximately $5.57 billion by 2026, driven by the increasing demand for efficient fluid control in industries such as oil and gas, water and wastewater treatment, and power generation. The use of bellows sealed gate valves significantly reduces the risk of environmental contamination and improves safety standards.

In applications where precise flow control is essential, bellows sealed gate valves provide better performance compared to traditional designs. The bellows eliminate the need for packing, which is a common source of leaks in standard valves. This innovation not only enhances the valve's lifespan but also minimizes maintenance costs, as stated in a study published by the American Society of Mechanical Engineers. Furthermore, these valves can withstand extreme temperatures and pressures, making them ideal for demanding environments, including cryogenic applications and steam services. By ensuring reliable operation and reducing the likelihood of failure, bellows sealed gate valves are increasingly recognized as a premium choice for industries requiring high-performance sealing solutions.

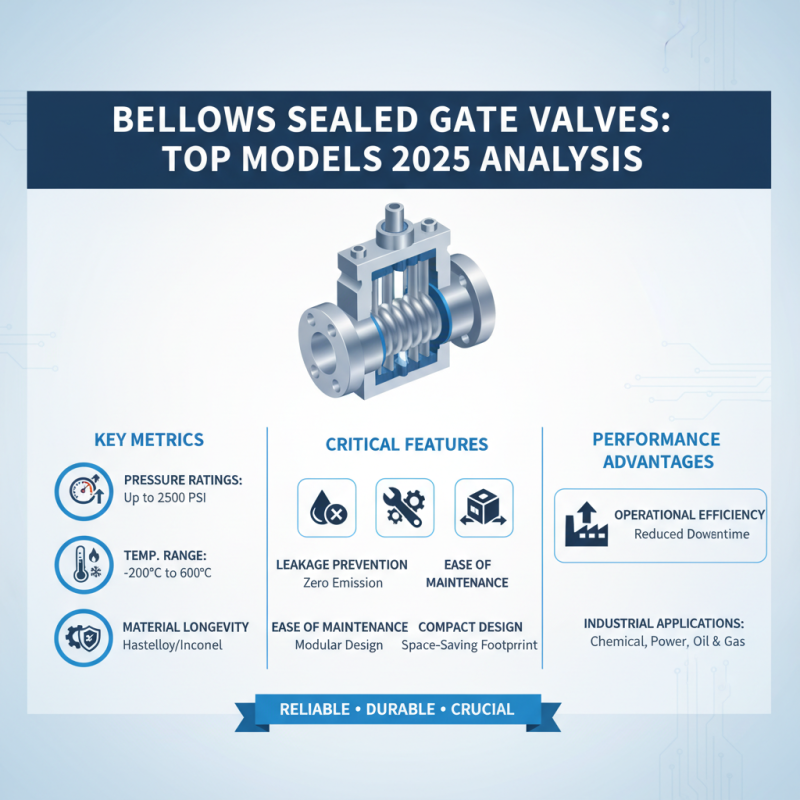

In 2025, the demand for reliable and durable bellows sealed gate valves has spurred a comparative analysis of the top models available in the market. These valves are crucial in applications where leakage prevention is paramount, making their design and construction critical. The analysis focuses on key performance metrics such as pressure ratings, temperature ranges, and the longevity of materials used in their manufacture. Notably, factors like ease of maintenance, compact design, and operational efficiency also play an essential role in distinguishing the best options for industrial applications.

When evaluating the top bellows sealed gate valves, attention is given to innovative features that enhance reliability. Advanced sealing technologies and robust bellows designs contribute significantly to reducing the risk of environmental contamination and improving operational safety. Additionally, the comparative study assesses user feedback and performance reports, providing valuable insights into how these valves perform under various conditions. By prioritizing these attributes, industries can select gate valves that not only meet their operational requirements but also ensure long-term durability and ease of maintenance.

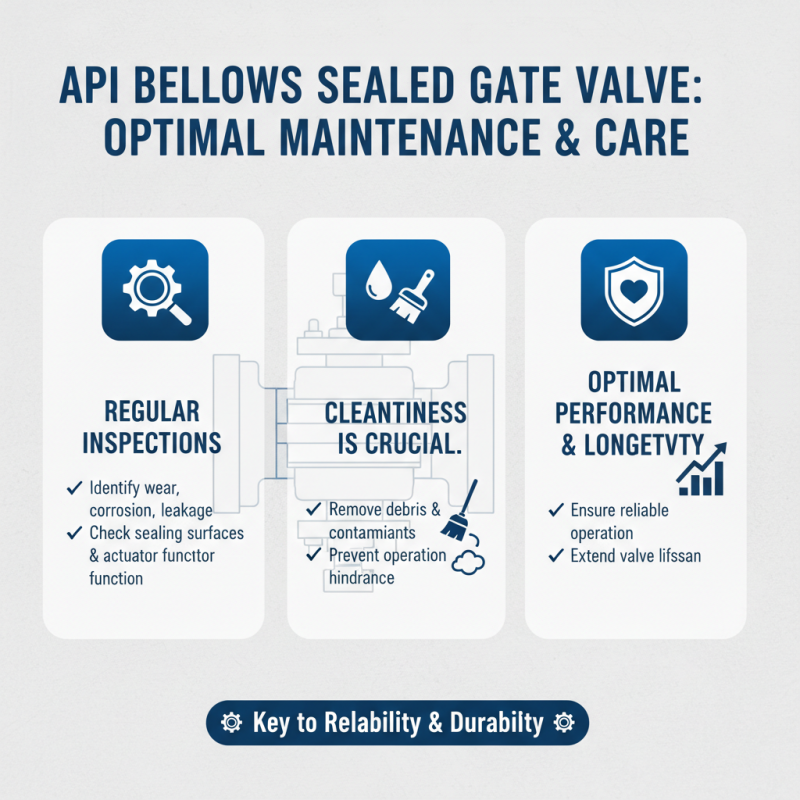

Proper maintenance and care of API bellows sealed gate valves are essential for ensuring their optimal performance and longevity. Regular inspections should be conducted to identify any signs of wear, corrosion, or leakage. During these inspections, it is important to check the sealing surfaces and the functionality of the valve actuators. Any buildup of debris or contaminants can hinder the operation of the valve, so keeping these components clean is crucial for reliable performance.

Additionally, lubrication of moving parts is vital to prevent friction and wear. Using the appropriate lubricant can enhance the valves' operational efficiency and reduce the risk of failure. It is also advisable to follow a scheduled maintenance routine, which includes replacing seals and gaskets as needed, according to the manufacturer's specifications or operating conditions. Implementing these maintenance strategies will not only extend the life of the valves but also ensure that they function effectively under varying pressures and temperatures. Regular training for personnel responsible for valve maintenance can further bolster performance and safety measures in the operation of these critical components.