+86 19720579616

+86 19720579616

Zalo

Zalo

When selecting Forged Steel Globe Valves, various factors come into play. These valves are essential in controlling fluid flow and pressure in pipelines. Their durability and reliability make them popular in many industries. However, not all forged steel valves are created equal.

The material quality, sizing, and design can vary greatly. It’s vital to inspect the specifications closely. A well-chosen valve can lead to efficient operations. A poorly selected one can cause issues like leaks or failures. Consider the specific requirements of your project. Each application may demand unique features.

In the end, prioritizing the right characteristics is crucial. Opt for brands with a solid reputation in the market. Understanding fundamental aspects can save time and money. Seek advice if uncertain. This thoughtful approach ensures effective solutions in your system.

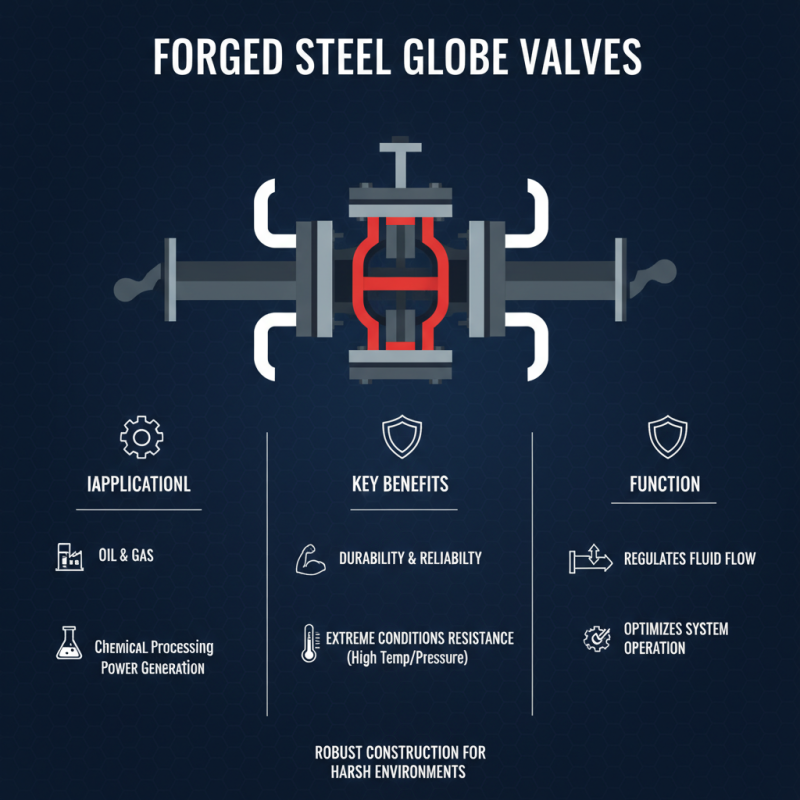

Forged steel globe valves play a significant role in various industrial applications. Their durability and resistance to extreme conditions make them reliable components in pipelines. These valves are essential for regulating fluid flow, ensuring systems operate smoothly. Their robust construction can withstand high pressure and temperature, making them ideal for harsh environments.

In industries like oil and gas, forged steel globe valves are vital. They help maintain safety and efficiency. However, choosing the right valve requires careful consideration. Factors such as size, pressure rating, and material compatibility are critical. Oversights in these areas can lead to costly failures.

Understanding the importance of proper selection is key. Inadequate valves may cause leaks or system breakdowns. Maintenance becomes a challenge with poor choices. Reflecting on past experiences can guide future decisions. Investing time in research can save money and enhance operational reliability.

When selecting forged steel globe valves, material selection is crucial. Different alloys offer varying levels of performance and durability, impacting valve efficiency. Consider stainless steel, carbon steel, and alloy steel as common choices. Each material has unique properties. Stainless steel resists corrosion well, ideal for harsh environments. Carbon steel is cost-effective but less tolerant to extreme conditions. Alloy steel combines strength and durability, making it suitable for high-pressure applications.

Tip: Always check the application requirements before making a material choice. Does the environment demand resistance to chemicals? What temperatures or pressures will the valves face? These questions guide your selection.

Sometimes, the wrong choice can lead to failure. Misjudging the service conditions can cause significant issues. Ensuring proper fit for intended use is essential. Investing time in evaluating alloy properties pays off in the long run. Ensure that you balance performance with cost. High durability may come at a price, so weigh your options carefully.

When selecting forged steel globe valves, understanding pressure rating standards is crucial. These ratings determine how much pressure a valve can safely handle. For any industrial application, pressure ratings ensure the valve operates safely under various conditions. High-pressure systems require valves designed to sustain extreme forces without leakage.

Consider the critical details of the pressure rating. There are several standards, including ANSI and API. Each provides guidelines for operating conditions. Stainless steel valves may have different ratings than carbon steel options. Know the differences to make informed choices.

Tip: Always check the maximum pressure capacity for your specific application. A valve that fails under pressure can lead to severe accidents. Do not compromise on this aspect.

Another important factor is temperature limits. The pressure rating can change based on temperature. Extreme heat or cold can affect a valve's integrity. Make sure to assess the operating temperatures in your environment and select valves accordingly.

Tip: Look for valves that meet your specific needs. Standard options may not suit unusual operating conditions. Custom solutions can be more effective.

When selecting forged steel globe valves, proper sizing and understanding flow characteristics are crucial. A well-sized valve enhances system efficiency effectively. Oversized valves can create unnecessary turbulence. Undersized ones may restrict flow or lead to increased wear. Many overlook these details, focusing too much on price or material alone.

Consider the application’s flow rate and pressure conditions. Choose a valve that aligns with these requirements. Flow characteristics influence not just efficiency but also longevity. A valve operating outside its optimal range can fail prematurely. Regular assessments are essential to ensure ongoing performance.

Take into account the specific system layout. Curved pipelines can impact flow, and valve placement is vital. Sometimes, a less-than-ideal setup can lead to unexpected issues. Reflect on your installation; is it optimized? Always remember that even minor adjustments can yield significant benefits.

When selecting forged steel globe valves, considering installation and maintenance is crucial for long-term reliability. Proper installation ensures optimal performance. Misalignment during installation can lead to leaks and premature wear. According to a recent industry report, nearly 25% of valve failures stem from improper installation. These failures can significantly impact system efficiency and safety.

Here are a few essential tips for installation. Use appropriate sealants to prevent leaks. Ensure that the valve is oriented correctly in the piping system. This helps facilitate smooth flow. Regularly check for any signs of wear or corrosion after installation. Neglecting these checks could lead to substantial repair costs.

Maintenance is equally important. Routine inspections can identify potential issues before they escalate. For instance, cleaning valves can enhance their lifespan. Regular maintenance has been shown to extend valve lifespan by up to 40%, as stated in various industry analyses. Be mindful that even minor neglect can have significant ramifications. Each component in a piping system relies on its neighbors for optimal functionality.