+86 19720579616

+86 19720579616

Zalo

Zalo

Choosing the right Din Gate Valves for your projects is crucial to ensure efficiency and reliability in fluid control systems. As industry expert Dr. Sarah Thompson, a renowned mechanical engineer with over 20 years of experience in valve technology, once stated, "Selecting the appropriate Din Gate Valves can be the difference between a successful project and unexpected downtime." This statement underscores the importance of meticulous consideration when it comes to valve selection.

In the dynamic landscape of industrial applications, understanding the characteristics and specifications of Din Gate Valves is paramount. These valves, known for their robust design and superior sealing capabilities, play a critical role in various sectors, including oil and gas, water treatment, and chemical processing. With countless options available on the market, making an informed choice can significantly impact project outcomes, operational efficiency, and maintenance costs.

In this guide, we will delve into essential tips for navigating the complexities of Din Gate Valves selection. By focusing on key factors such as material compatibility, pressure ratings, and operational requirements, you'll be equipped to make well-informed decisions that align perfectly with your project goals.

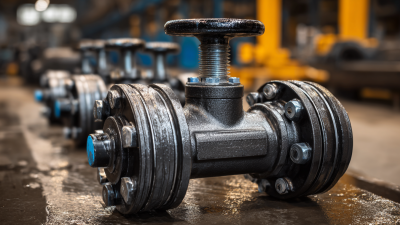

When selecting the right DIN gate valves for your projects, understanding the key characteristics that define their performance is crucial. One of the primary factors to consider is the valve material. Different materials, such as cast iron, stainless steel, and brass, offer varying degrees of strength, corrosion resistance, and suitability for specific environments. Depending on the fluids or gases being controlled, choosing the appropriate material can significantly influence the lifespan and reliability of the valve.

Another important characteristic is the valve size and pressure rating. It's essential to match the gate valve's dimensions and pressure tolerance with the specifications of your piping system. A valve that is too small may restrict flow, while one that cannot handle the system's pressure could lead to failures or leaks. Always refer to the system requirements and consult with experts if necessary to ensure proper compatibility.

Tips for selecting the right gate valve include conducting thorough research on your project's specific needs, maintaining a focus on environmental conditions, and evaluating the expected service life. Consider consulting technical data sheets and engaging with professionals who can provide insights into the most effective choices for your application. Taking the time to evaluate these characteristics thoroughly will help ensure your project's success and operational efficiency.

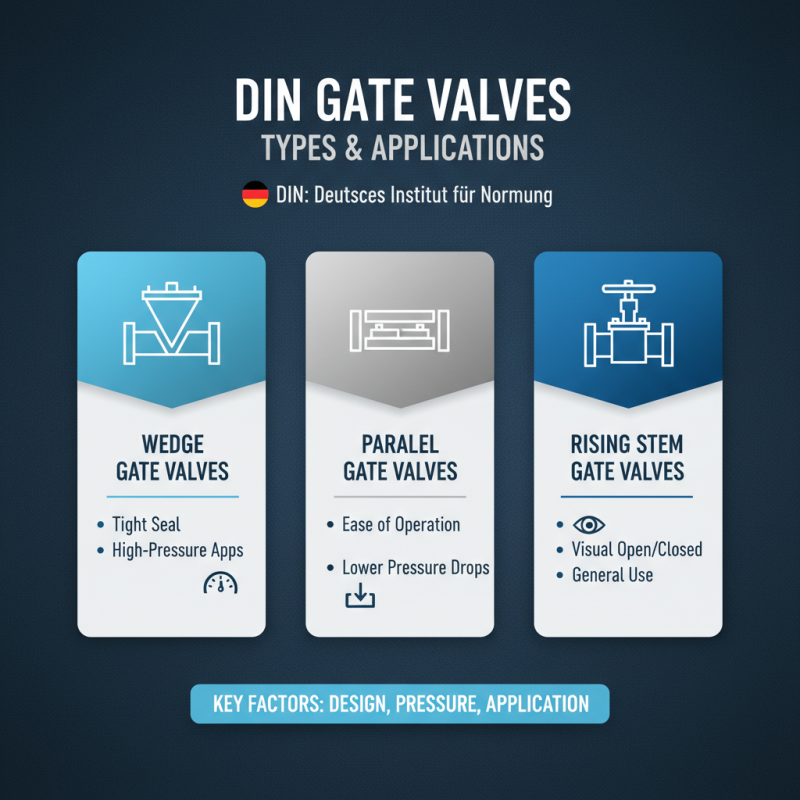

When embarking on projects that require the use of DIN gate valves, it’s essential to understand the various types available in the market. DIN (Deutsches Institut für Normung) gate valves are primarily categorized by their design features, pressure ratings, and application suitability. Common variations include wedge gate valves, parallel gate valves, and rising stem gate valves, each catering to specific operational needs. For instance, wedge gate valves are widely recognized for their ability to provide a tight seal and are often utilized in high-pressure applications, while parallel gate valves are preferred for their ease of operation and lower pressure drops.

Tips for selecting the right DIN gate valve include evaluating the pressure and temperature specifications of your project. According to industry reports, up to 50% of performance issues in fluid systems can be traced back to improper valve selection. It is vital to assess the materials used in the valve construction, particularly if the application involves corrosive substances. Understanding the flow characteristics and ensuring compatibility with existing piping systems can significantly mitigate maintenance costs over time.

Another crucial factor is the certification and compliance with industry standards. DIN gate valves should meet specific criteria to ensure safety and reliability. Utilizing valves that conform to recognized standards not only improves the safety of your systems but also aids in achieving long-term operational efficiency. Data from flow control professionals indicate that projects utilizing compliant valves can experience up to a 20% increase in system uptime due to reduced failures and maintenance requirements.

When selecting the right DIN gate valves for your projects, material selection is a crucial factor that can significantly impact the durability and performance of the valves. The most commonly used materials include

cast iron,

stainless steel, and

brass, each offering unique benefits suited to different applications.

Cast iron, for instance, is known for its excellent wear resistance and ability to withstand high pressures, making it ideal for water and sewage systems. Conversely,

stainless steel provides enhanced corrosion resistance and is often preferred in industries involving chemicals or food processing, where hygiene and safety are paramount.

Another material option to consider is

brass, which, while not as robust as stainless steel or cast iron, offers good corrosion resistance in less demanding environments. Its lightweight nature can also be beneficial in applications where reducing overall weight is a priority. Additionally, advancements in composite materials have expanded the choices available, providing solutions that combine strength with reduced weight and corrosion resistance. Ultimately, the right material choice depends on the specific requirements of your project, including environmental factors, operating conditions, and longevity expectations, ensuring that the selected

DIN gate valves will perform optimally over their expected lifespan.

When selecting din gate valves for your projects, proper sizing and compatibility are critical to ensuring optimal performance and durability. The American Society of Mechanical Engineers (ASME) recommends that the valve size should match the piping system to prevent potential issues such as pressure loss or increased wear due to misalignment. A recent industry report indicates that improperly sized valves can lead to efficiency losses of up to 30%, underscoring the importance of careful selection.

Moreover, compatibility with existing systems cannot be overlooked. Factors such as material compatibility, pressure ratings, and temperature specifications play crucial roles in preventing corrosion and ensuring longevity. According to the Valve Manufacturers Association (VMA), approximately 40% of valve failures in industrial applications can be attributed to material incompatibility. Therefore, assessing the properties of the fluids being controlled and the working environment is essential to guarantee that the chosen din gate valve will perform reliably throughout its intended service life.

Engaging in a thorough evaluation of these factors prior to procurement will greatly contribute to the success of your project.

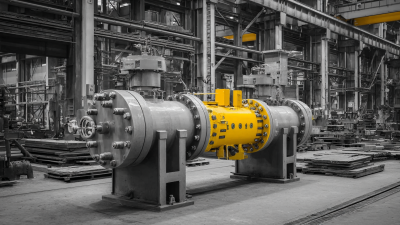

When it comes to the maintenance and longevity of DIN gate valves, understanding their operational environment and adhering to best practices is crucial. According to a report from the International Journal of Engineering Research and Technology, improper maintenance can significantly reduce the lifespan of these valves, which typically ranges from 15 to 30 years under optimal conditions. Regular inspections and timely servicing can prevent common wear and tear that may lead to leaks or valve failure, particularly in high-pressure systems where the demand for reliability is paramount.

To maximize the efficiency of DIN gate valves, it's essential to implement a structured maintenance plan. The American Society of Mechanical Engineers (ASME) recommends performing routine checks on valve seating surfaces, seals, and actuators to ensure they function correctly. Moreover, addressing corrosion and wear through protective coatings can enhance valve performance and lifespan. For instance, using materials resistant to the operating medium and environmental factors plays a significant role in reducing maintenance needs and enhancing operational reliability. By prioritizing proactive maintenance strategies, project managers can ensure that their systems operate efficiently while minimizing costly downtimes and repairs.