+86 19720579616

+86 19720579616

Zalo

Zalo

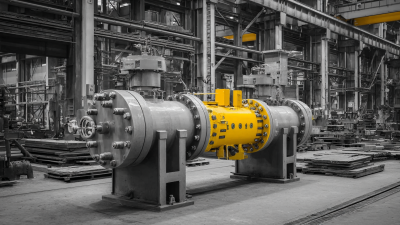

In the ever-evolving landscape of industrial processes, the critical role of reliable valve systems cannot be overstated. Forged Steel Ball Valves are emerging as a paramount choice, thanks to their superior strength, durability, and efficient performance under high-pressure environments. According to a recent market analysis by Industry Research, the global valve market is projected to reach $102.33 billion by 2025, with forged steel ball valves accounting for a significant share due to their versatile applications across various sectors, including oil and gas, chemical processing, and water treatment. Their ability to minimize energy loss and enhance flow control makes them a vital component in maximizing operational efficiency. As industries strive to optimize their processes, integrating Forged Steel Ball Valves not only contributes to reduced maintenance costs but also aligns with sustainable practices by lowering energy consumption and emissions.

Forged steel ball valves play a crucial role in maximizing flow control efficiency across various industrial applications. Their robust construction allows them to endure high-pressure environments while maintaining a tight seal, which is essential for preventing leaks and ensuring smooth operation. The precision design of these valves facilitates quick opening and closing, minimizing flow turbulence and energy loss. As industries continue to prioritize efficiency and sustainability, incorporating forged steel ball valves has become a strategic advantage in optimizing fluid management systems.

Tips: When selecting forged steel ball valves, consider the system’s pressure and temperature conditions to ensure compatibility. It's also advisable to choose valves with a streamlined flow path, as this can further enhance efficiency by reducing pressure drops. Furthermore, regular maintenance checks can prevent wear and prolong the life of the valves, ensuring they remain reliable over time.

In addition to their mechanical benefits, forged steel ball valves contribute to overall operational efficiency by reducing downtime. Their durable design and minimal maintenance requirements make them ideal for applications where reliability is paramount. By integrating these valves into process systems, industries can achieve not only increased flow control efficiency but also a significant boost in productivity.

Forged steel ball valves have emerged as a crucial component in optimizing maintenance costs for industrial applications. These valves are designed to withstand high pressures and temperatures, which not only enhances their durability but also minimizes the frequency and costs associated with repairs. According to a recent report by the Flow Control Magazine, industries utilizing forged steel ball valves have seen maintenance costs reduce by up to 30% compared to traditional valve types. This reduction is due to the comprehensive reliability of forged steel, which significantly decreases the likelihood of valve failure and subsequent downtime.

Tips: To further maximize cost efficiency, consider conducting regular inspections and implementing a predictive maintenance program. These strategies can help identify potential issues before they escalate, ensuring your forged steel ball valves operate at peak performance.

Additionally, the installation of these valves can lead to improved process consistency, which drives productivity. In studies conducted across manufacturing sectors, the installation of high-quality forged steel ball valves contributed to a 15% increase in operational efficiency. By investing in reliable valve technology, industries not only enhance their production processes but also create significant long-term savings in maintenance and operational expenses.

Forged steel ball valves have become a cornerstone in industrial applications, largely due to their impressive durability and longevity. The inherent properties of forged steel, such as its high tensile strength and resistance to wear and corrosion, contribute significantly to the operational lifespan of these valves. Statistical analyses indicate that properly maintained forged steel ball valves can last upwards of 15 to 30 years, depending on the operating conditions. This remarkable durability reduces downtime and maintenance costs, making them an economically viable choice for many industries.

Moreover, the design of forged steel ball valves enhances their efficiency in handling various media under high pressure and temperature conditions. Tests have shown that these valves exhibit minimal leakage and high sealing performance over extended periods, further reinforcing their reliability. Industries ranging from oil and gas to chemical processing have reported a substantial reduction in failure rates when using forged steel ball valves. These statistics not only underscore the importance of material selection in valve manufacturing but also highlight the long-term benefits of investing in high-quality forged steel solutions for industrial usage.

Forged steel ball valves play a crucial role in enhancing safety standards across various industrial applications. According to the American Society of Mechanical Engineers (ASME), these valves are not only designed for superior performance but also adhere to stringent industry regulations that ensure safety and reliability. The robust construction of forged steel provides enhanced durability and resistance to high pressures and temperatures, making them ideal for critical systems in oil and gas, chemical processing, and water treatment facilities.

Furthermore, industry reports indicate that compliance with the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) significantly influences the selection of valves. For instance, a study published by the International Journal of Pressure Vessels and Piping highlights that incorrectly selected or improperly installed valves can lead to catastrophic failures, emphasizing the need for compliance with established safety protocols. By utilizing forged steel ball valves that meet these rigorous standards, industries can mitigate risks, ensure operational safety, and optimize performance, illustrating their essential role in modern industrial applications.

Forged steel ball valves are increasingly recognized for their efficiency in various industrial applications, largely due to their significant performance metrics related to flow rates and pressure drops. According to the International Journal of Engineering Research and Applications, the design of forged steel valves contributes to minimized turbulence and lower pressure loss, making them ideal for high-flow environments. With flow rates that can exceed 25 gallons per minute (GPM) at optimal pressure conditions, these valves outperform many traditional valve types, offering superior control over fluid dynamics.

Furthermore, industry reports indicate that well-designed forged steel ball valves can achieve pressure drops as low as 1 psi across the valve, depending on the size and specific application, compared to the more common 3-5 psi in standard industrial valves. This reduction not only enhances overall system efficiency but also translates to energy savings, particularly in large-scale operations. As manufacturers continue to innovate with advanced forging techniques, the potential for maximizing efficiency in industrial processes through these valves becomes increasingly apparent, demonstrating their critical role in modern fluid management systems.