+86 19720579616

+86 19720579616

Zalo

Zalo

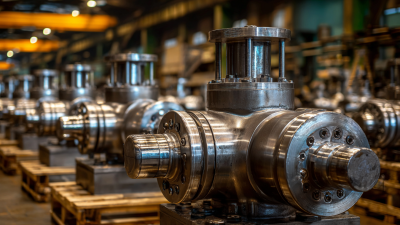

In today's rapidly evolving industrial landscape, the reliance on high-quality components is paramount for ensuring both safety and efficiency. Among these components, Forged Steel Valves have emerged as a critical element in various applications, ranging from oil and gas to chemical processing. According to a recent market report by Research and Markets, the global valve market is projected to reach $87.8 billion by 2026, driven in part by the demand for robust and durable materials that withstand extreme pressures and temperatures.

Forged steel valves play a crucial role in demanding

high-pressure applications across various industries. According to a report by

the Global Valve Market Analysis, the global demand for forged steel valves is

projected to reach approximately $20 billion by 2025, highlighting

their significance in ensuring safety and operational efficiency. These valves are engineered to withstand extreme

pressures, with many models rated to handle pressures up to 10,000 psi, making

them indispensable in sectors like oil and gas, chemical processing,

and power generation.

Statistical data also indicate that forged steel valves reduce the risk of leaks and failures by over

40% compared to their cast counterparts. This is largely due to their

superior structural integrity and resistance to mechanical stress. A study published in the

Journal of Pressure Vessel Technology found that the lifespan

of forged steel valves can exceed 25 years in high-pressure

environments, thereby not only enhancing workplace safety but also minimizing maintenance costs and downtime.

As industries continue to evolve, the reliance on forged steel valves is expected to grow, making them

essential components of modern industrial infrastructure.

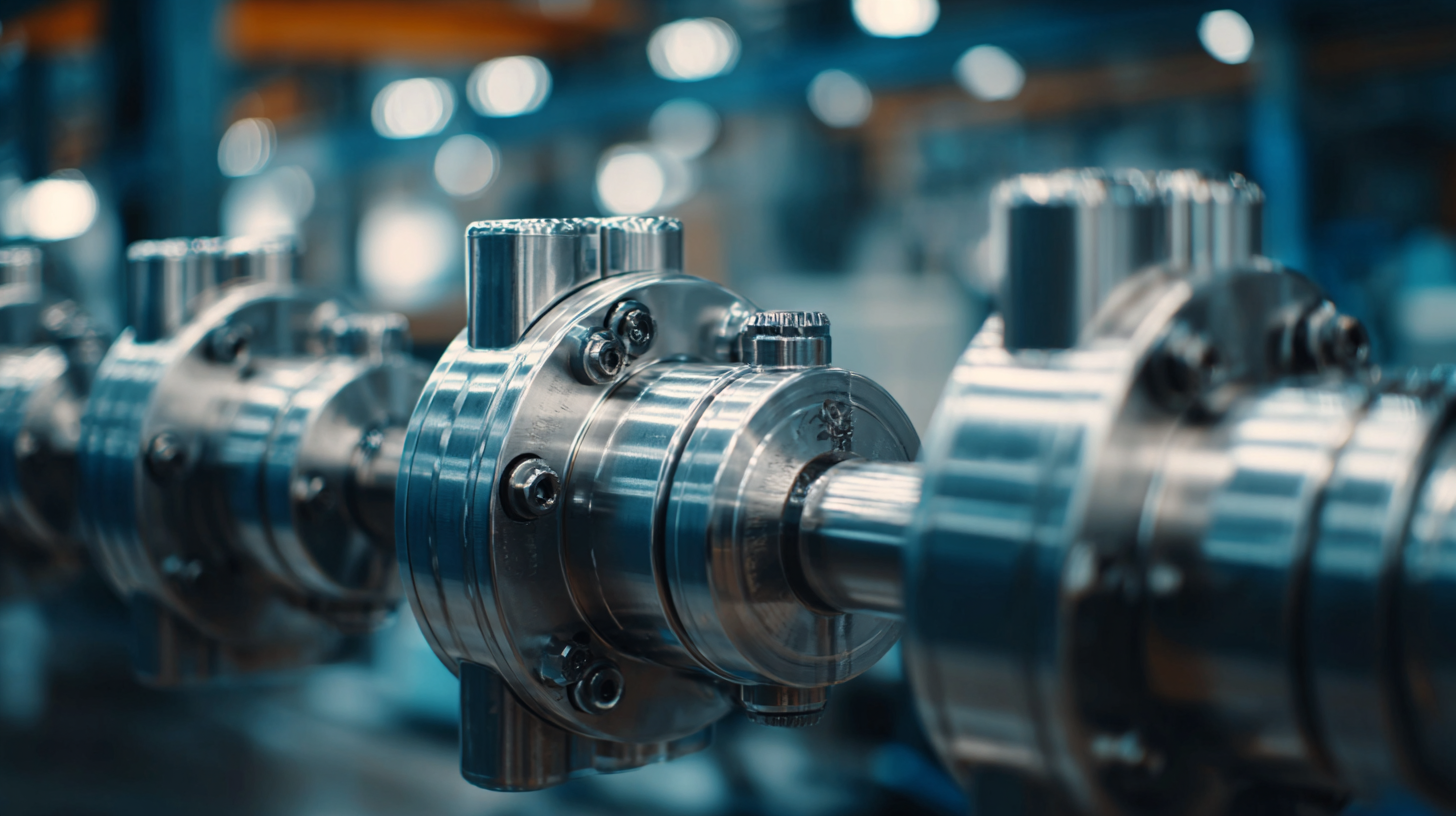

Forged steel valves play a pivotal role in enhancing energy efficiency within manufacturing processes. According to a 2022 report by the International Energy Agency (IEA), optimizing valve performance can lead to energy savings of up to 30% in some industrial applications. The precision and durability offered by forged steel construction ensure minimal leakage and better flow control, which directly impacts operational efficiencies.

In sectors such as oil and gas, the effectiveness of forged steel valves is further illustrated by a study from the American Society of Mechanical Engineers (ASME), indicating that leveraging high-performance valves can reduce overall energy consumption in pipelines by as much as 25%. This reduction not only lowers operational costs but also contributes to sustainability goals, as industries are increasingly held accountable for their environmental impact. By integrating forged steel valves into their systems, manufacturers can significantly enhance both safety and efficiency, making them a critical element in modern industrial applications.

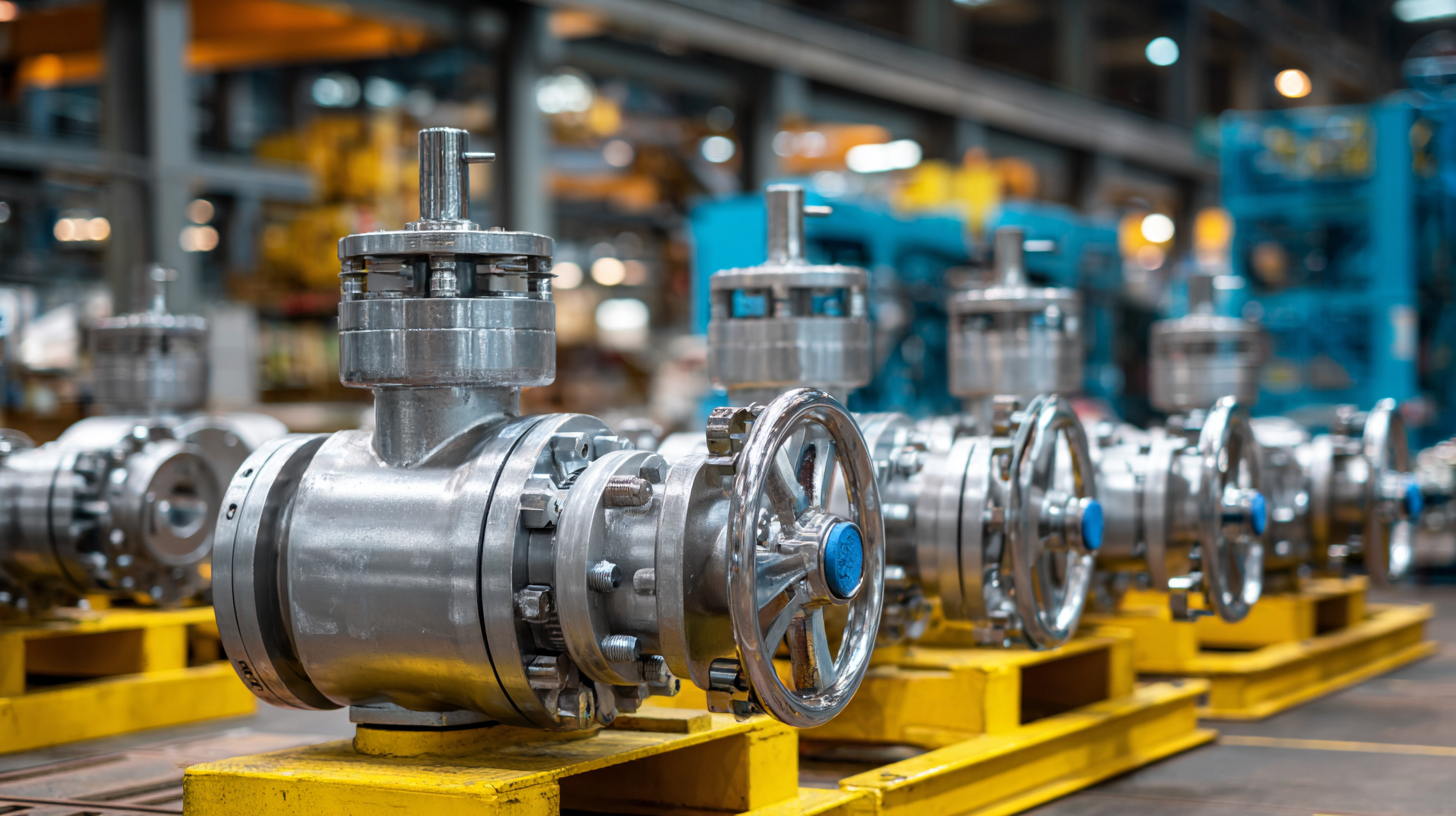

In the modern industrial landscape, the choice between forged steel valves and cast iron valves can significantly impact operational efficiency and safety. A comparative durability analysis reveals that forged steel valves generally offer superior performance under high-pressure and high-temperature conditions. According to the American Society of Mechanical Engineers (ASME), forged steel valves can withstand pressures up to 20,000 psi, while most cast iron valves are limited to around 200-300 psi. This stark contrast makes forged steel valves essential for industries that require reliable performance and safety, such as oil and gas or chemical processing.

Furthermore, longevity plays a crucial role in reducing overall maintenance costs. A study from the National Institute of Standards and Technology (NIST) indicates that forged valves can surpass lifespans of 25 years, while cast iron alternatives often need replacement within 5-10 years under similar conditions. This durability translates to fewer shutdowns and reduced operational disruptions, substantially enhancing productivity. In high-stakes environments where failure can result in significant financial loss or safety hazards, the reliance on forged steel valves becomes a critical component of an efficient and secure industrial operation.

This chart compares the durability of forged steel valves and cast iron valves in various industrial applications based on factors like tensile strength, resistance to wear, and operating temperature limits.

Investing in forged steel valves can yield significant long-term benefits for industrial operations. According to a report by the MarketsandMarkets research firm, the global valve market is projected to reach approximately $82 billion by 2025, with forged steel valves accounting for a substantial share due to their superior durability and reliability. These valves are engineered to withstand extreme temperatures and high pressures, making them a critical component in industries such as oil and gas, power generation, and water treatment. The initial investment may be higher compared to conventional valves, but the long-term savings derived from reduced maintenance costs and lower failure rates can be considerable.

Furthermore, a study published in the Journal of Pressure Vessel Technology indicates that using forged steel valves can extend service life by up to 50% when compared to cast alternatives. This longevity translates to fewer replacements over time, ultimately leading to significant cost savings in both operational management and materials procurement. Additionally, the enhanced safety features associated with forged steel valves help mitigate the risks of leaks or failures, which can lead to costly downtime and safety incidents. Thus, the strategic investment in forged steel valves not only improves efficiency but also contributes to a safer working environment, reinforcing their essential role in modern industrial applications.

In modern industry, safety standards and regulations are paramount, and forged steel valves play a crucial role in ensuring compliance and effective risk management. These valves are designed to withstand high pressure and temperature, making them ideal for use in critical applications, including oil and gas, chemical processing, and power generation. Their robust construction not only meets stringent regulatory requirements but also minimizes the risk of catastrophic failures that could result from equipment malfunction.

Furthermore, the reliability of forged steel valves contributes significantly to overall operational efficiency. By maintaining tight seals and reliable flow control, these valves help prevent leaks and spills, thus adhering to environmental safety regulations. Regular use of forged steel valves ensures that industries not only comply with national and international safety standards but also foster a culture of safety and responsibility. As regulations continue to evolve, the role of these valves in supporting compliance and managing risk will remain integral to the operational frameworks of modern industrial facilities.

| Dimension | Description | Importance |

|---|---|---|

| Material Strength | Forged steel valves offer superior tensile and impact strength, making them suitable for high-pressure applications. | Reduces the risk of failures that could lead to safety hazards. |

| Temperature Resistance | Able to withstand high temperatures without losing structural integrity. | Ensures efficient operation in various industrial processes. |

| Regulatory Compliance | Manufactured to meet strict industry standards and regulations. | Helps companies avoid legal issues and enhances safety protocols. |

| Leak Resistance | Designed to prevent leakage under high pressure. | Critical for maintaining system integrity and environmental safety. |

| Maintenance Frequency | Lower maintenance needs due to durability and high performance. | Reduces downtime and operational costs in industrial settings. |