+86 19720579616

+86 19720579616

Zalo

Zalo

In the realm of modern industrial applications, Din Bellows Sealed Valves have emerged as a critical component due to their exceptional sealing capabilities and reliability. According to a report by MarketsandMarkets, the global industrial valve market is expected to reach USD 80 billion by 2026, driven by increasing demand for efficient fluid control systems across various sectors, including oil and gas, chemicals, and water treatment.

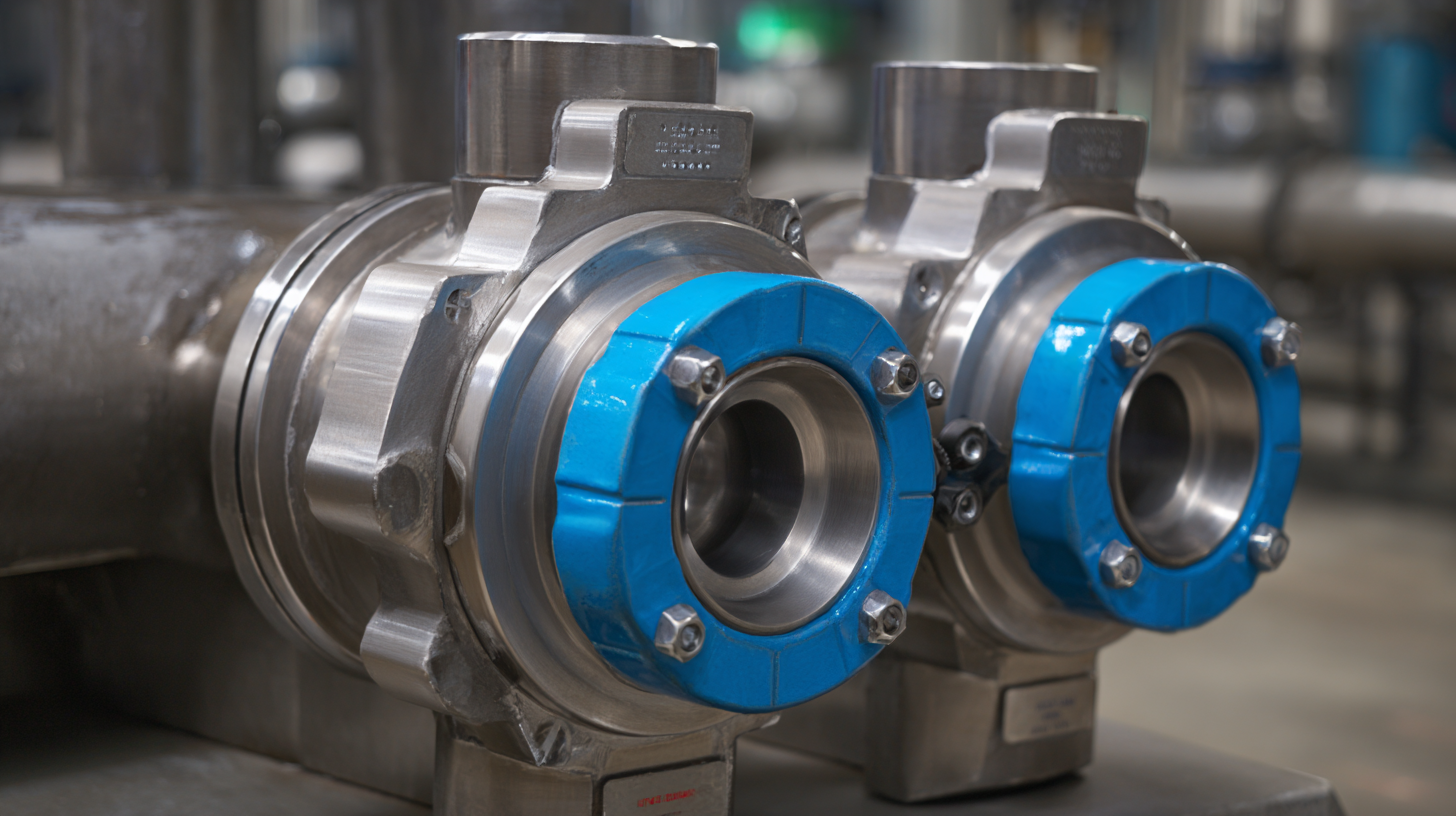

Din Bellows Sealed Valves, recognized for their ability to prevent leakage and ensure a contaminant-free environment, play a vital role in maintaining operational safety and efficiency. With their innovative design that minimizes the risk of external leakage, these valves significantly enhance performance in high-pressure and high-temperature applications. As industries continue to prioritize sustainability and safety, the importance of Din Bellows Sealed Valves cannot be overstated, making them indispensable for modern engineering solutions.

Din Bellows Sealed Valves, recognized for their ability to prevent leakage and ensure a contaminant-free environment, play a vital role in maintaining operational safety and efficiency. With their innovative design that minimizes the risk of external leakage, these valves significantly enhance performance in high-pressure and high-temperature applications. As industries continue to prioritize sustainability and safety, the importance of Din Bellows Sealed Valves cannot be overstated, making them indispensable for modern engineering solutions.

In modern industrial applications, Din bellows sealed valves play a crucial role in ensuring operational efficiency and safety. These valves, which use a flexible bellows to create a tight seal, effectively prevent the leakage of fluids and gases. According to a recent industry report by Research and Markets, the global demand for high-performance sealing solutions, including bellows sealed valves, is expected to grow at a CAGR of 5.7% through 2025, reflecting their increasing importance in sectors such as oil and gas, pharmaceuticals, and chemical processing.

The functionality of Din bellows sealed valves is rooted in their design and material composition, which allows them to withstand high pressures and temperatures without compromising integrity. They are particularly beneficial in corrosive environments where traditional sealing methods may fail. The ability of these valves to maintain a leak-proof seal minimizes the risk of contamination and enhances workplace safety. Moreover, their durability reduces maintenance costs, making them a preferred choice for many industrial operators.

**Tips for Choosing Din Bellows Sealed Valves:**

1. Assess the chemical compatibility of valve materials with the fluids being handled to ensure longevity and performance.

2. Consider the expected pressure and temperature conditions to select a valve that can operate efficiently within those parameters.

3. Regularly inspect and maintain bellows seals to prevent unexpected failures, thereby enhancing overall system reliability.

| Application Area | Functionality | Benefits | Common Materials |

|---|---|---|---|

| Chemical Processing | Prevents leakage of hazardous materials | Enhanced safety and reduced environmental risks | Stainless Steel, PTFE |

| Oil and Gas | Handles high pressures and temperatures | High durability and reliability | Carbon Steel, Alloy Steel |

| Pharmaceuticals | Maintains sterile environments | Prevention of contamination | 316L Stainless Steel |

| Water Treatment | Controls flow rates effectively | Improved system efficiency | PVC, CPVC |

| Food Processing | Ensures cleanliness and prevents contamination | Compliance with health regulations | S316 Stainless Steel, Silicone |

Din bellows sealed valves offer significant advantages in modern industrial applications, particularly in process control systems. One of the key benefits of these valves is their exceptional ability to prevent leakage, which is critical in maintaining the integrity of various processes. As industries increasingly adopt sensor-based technologies to enhance operational efficiency, the need for reliable and leak-proof components such as Din bellows sealed valves becomes paramount. Their design ensures that they can withstand high pressures and extreme temperatures while providing a secure seal, thus minimizing the risk of contamination.

Furthermore, the growing importance of data integrity in industrial applications aligns with the benefits that Din bellows sealed valves provide. In environments where precise control over fluid flows is essential, these valves enable accurate pressure regulation and flow management. With the signal conditioning module market projected to exceed $1.4 billion by 2023, partly due to this heightened demand for sensor technology, the role of robust components like bellows sealed valves becomes even more crucial. Their reliability not only enhances process control but also contributes to overall system performance and safety, making them an indispensable part of any modern industrial setup.

Din bellows sealed valves play a crucial role in modern industrial applications, particularly within the chemical and oil industries. These valves are specifically designed to maintain a hermetic seal between the valve body and the environment, reducing the risk of leaks. This is essential in sectors where toxic or corrosive substances are handled, as even minor leaks can lead to significant safety hazards and environmental damage. By utilizing bellows technology, these valves prevent contamination and ensure that hazardous materials do not escape into the surroundings.

In the chemical industry, the versatility of din bellows sealed valves allows for their use in various processes such as fluid control, mixing, and transfer operations. Their ability to withstand high pressures and temperatures ensures reliable performance under demanding conditions. Similarly, in the oil industry, these valves are critical for controlling the flow of crude oil and its derivatives while minimizing the risk of leaks. As companies increasingly prioritize safety and environmental regulations, the adoption of din bellows sealed valves is likely to expand, reflecting their importance in protecting both personnel and the planet.

In modern industrial applications, the choice of valve type can greatly impact system efficiency and safety. Comparative analysis reveals that DIN bellows sealed valves offer significant advantages over traditional valve types, particularly in terms of leak prevention and maintenance costs. According to a recent report from the Valve Manufacturers Association, bellows sealed valves can reduce leakage by up to 95% compared to conventional designs, making them ideal for use in critical applications such as chemical processing and pharmaceuticals, where even minor leaks can lead to catastrophic results.

Moreover, DIN bellows sealed valves are engineered for longevity with less need for maintenance. Industry statistics indicate that facilities using traditional valves face an average of 11% higher unplanned downtime due to leaks and failures. In contrast, the robust design of bellows sealed valves can lead to decreased operational interruptions, providing approximately 30% lower total cost of ownership over the valve's life cycle. This reliability not only enhances productivity but also aligns with stringent environmental regulations, further solidifying the role of DIN bellows sealed valves as a pivotal component in modern industrial operations.

Din bellows sealed valves play a crucial role in maintaining the integrity and safety of industrial systems, particularly in sectors such as chemical processing and oil and gas. According to a recent report by MarketsandMarkets, the global valve market is projected to reach USD 93.88 billion by 2027, highlighting the increasing reliance on specialized valves like din bellows sealed variants. The design of these valves, featuring a bellows seal, minimizes leakage risks and enhances their application in environments where conventional valves might fail due to corrosive substances or extreme pressure.

Maintenance practices for din bellows sealed valves are essential to ensure their functionality and longevity. Regular inspections should focus on the condition of the bellows, as wear and fatigue can lead to performance deterioration. According to a study published by the Valve Manufacturers Association, improper maintenance can reduce valve life by up to 50%, dramatically impacting operational efficiency and safety. Implementing a proactive maintenance schedule, including monitoring for signs of wear and regular testing of the seal integrity, can significantly enhance durability and minimize unexpected downtimes, making these valves a reliable choice in today's demanding industrial applications.