+86 19720579616

+86 19720579616

Zalo

Zalo

Din Bellows Sealed Globe Valves are essential components in modern piping systems. They offer unique advantages over traditional valves. With a specialized design, these valves ensure minimal leakage. This is vital in many industries, such as oil and gas.

The bellows seal feature provides a reliable barrier against fluid leakage. It is particularly useful in high-pressure and high-temperature applications. The durability of Din Bellows Sealed Globe Valves contributes to their long service life. Regular maintenance prevents potential failures, but it’s sometimes overlooked. System operators must remain vigilant.

In certain situations, the initial cost of these valves can be higher. However, their efficiency and reliability often lead to long-term savings. Energy and fluid loss can be significant if standard valves are used. Therefore, investing in Din Bellows Sealed Globe Valves can prove beneficial. They represent a commitment to safety and performance. It’s clear that careful consideration is crucial in valve selection.

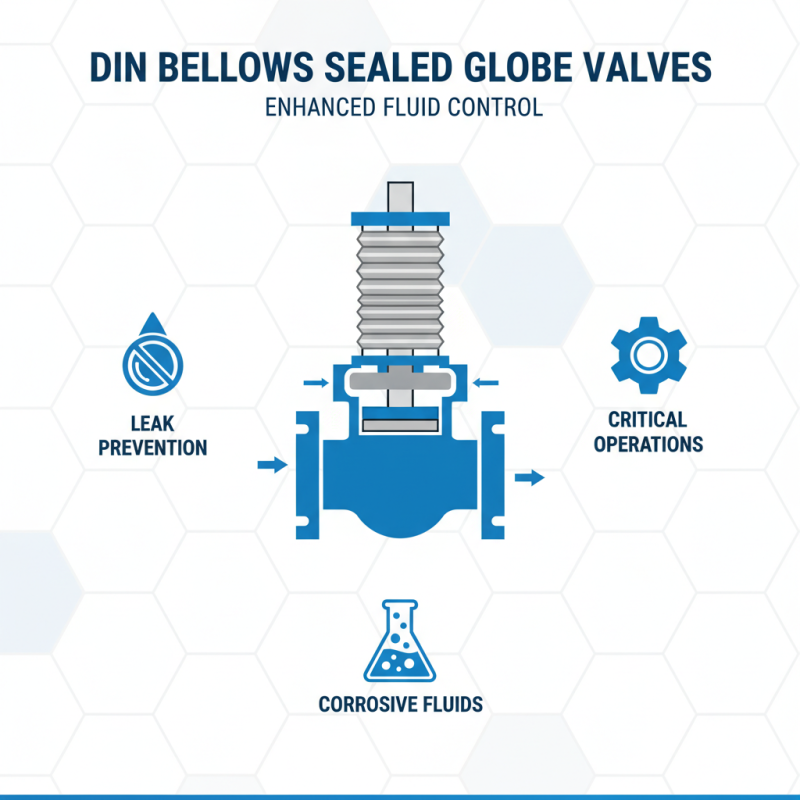

Din bellows sealed globe valves are essential components in various piping systems. They primarily function to control fluid flow in industry applications. Their design features a bellows seal, which keeps the fluid contained inside. This design minimizes the risk of leaks, making these valves reliable choices for critical operations. They are particularly useful in handling corrosive fluids.

The functionality of these valves is based on their specific structure. The bellows allow for movement without compromising the seal. This means that even with repeated use, leakage is significantly reduced. They are known for their durability. However, the installation process can be tricky. Proper alignment is crucial to ensure effective operation. If not installed correctly, issues may arise, leading to potential maintenance challenges.

Maintenance is another area where challenges occur. While the bellows provide excellent sealing, they can wear over time. Regular inspections are necessary to avoid unexpected failures. The potential for leaks increases as they age. It's crucial to plan for replacement and maintenance schedules. In conclusion, while Din bellows sealed globe valves offer notable advantages, attention to installation and maintenance is vital for optimal performance.

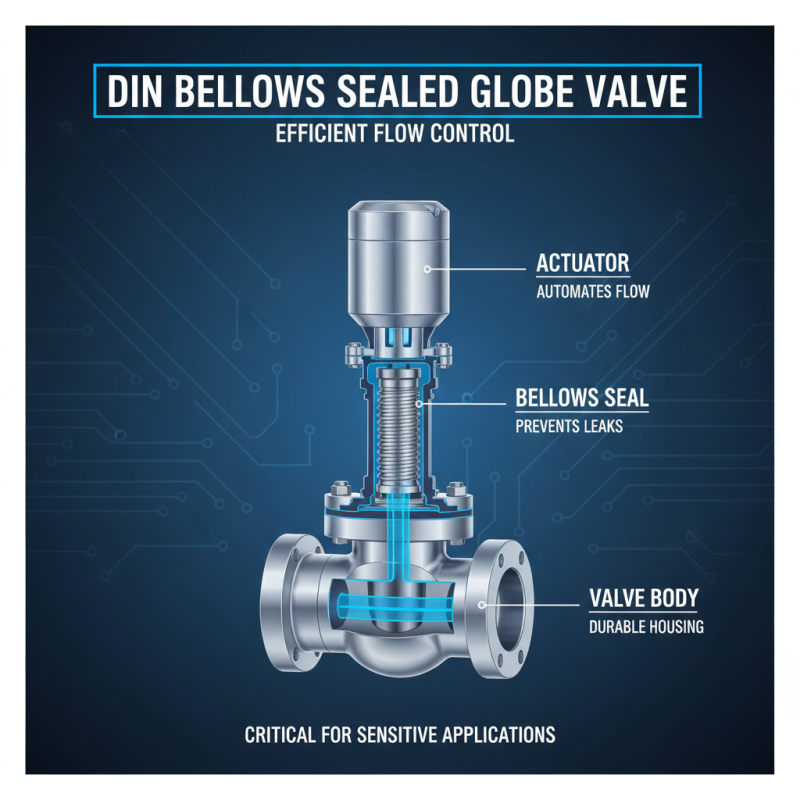

Din Bellows Sealed Globe Valves are designed for efficient flow control. Their key components include the body, bellows, and actuator. The bellows serve as a barrier, preventing leaks. This design feature is vital for sensitive applications.

One main advantage is the elimination of contamination. The bellows prevent media from coming into contact with the environment. This is crucial in industries like pharmaceuticals and food processing. The actuator can be manual or automated, increasing versatility.

**Tips:** Regular inspections are vital. Look for signs of wear in the bellows. Early detection may save costs. Ensure that the valve is compatible with the media it will handle. Mismatches can lead to performance issues.

Bellows sealed valves can be complex. Maintenance might be more involved compared to standard valves. Operators should be trained to handle the nuances of this technology. Understanding the design can prevent mishaps and enhance safety.

Din bellows sealed globe valves are gaining popularity across various industries. They are designed to prevent leakage, which is crucial in many applications. The bellows seal provides a robust barrier against media escape. This feature is particularly valuable in processes involving aggressive or hazardous materials. By using these valves, facilities can enhance safety and reduce environmental risks.

In applications like heating systems, water treatment, and chemical processing, Din bellows sealed globe valves offer reliable performance. They excel in controlling flow and pressure. The low maintenance requirement is another attractive benefit. Fewer repairs mean lower operational costs over time. However, it is essential to ensure proper installation. Misalignment can lead to failures, which will ultimately affect the system.

Tip: Always check the compatibility of the valve material with the media it will handle. This step prevents potential damage and ensures longevity. It’s worth noting that even small oversights can lead to significant issues. Make time for regular inspections as a preventive measure. Investing in quality valves like these can save you headaches down the road.

When comparing din bellows sealed globe valves to other types, several unique benefits emerge. These valves excel in handling difficult conditions. Their bellows sealing mechanism prevents leaks, making them ideal for sensitive applications. This feature sets them apart from traditional globe valves and other valve types, which may not offer the same level of sealing integrity.

Other valve types, like ball valves, provide quick shut-off capabilities. However, they may not withstand high pressure or temperature fluctuations as effectively as din bellows sealed globe valves. Butterfly valves are lightweight and cost-effective but may compromise on sealing in critical situations. Each valve type has its strengths and weaknesses, and the choice often depends on specific operational needs.

It’s crucial to weigh these benefits against potential drawbacks. Din bellows sealed globe valves might be more complex to install and maintain. Understanding these intricacies is key for decision-makers. They must consider reliability, functionality, and pricing when selecting the right valve for their operations.

Din bellows sealed globe valves are renowned for their durability and reliability in critical applications. However, like any mechanical device, they require regular maintenance. Neglecting their upkeep can lead to performance issues and costly downtime. According to industry reports, improper maintenance can reduce valve lifespan by up to 30%.

**Tip:** Regular visual inspections can help identify potential leaks early. Check for any visible damage or corrosion on the bellows and body. If any wear is observed, it’s crucial to take action immediately.

Addressing common issues promptly is pivotal. Over time, these valves can experience seat wear or packing failure. Troubleshooting typically involves checking the actuator for proper linkage and ensuring no debris is obstructing the valve's function. Consistent testing can help assess whether the valve closes fully without any resistance.

**Tip:** Keep a log of maintenance activities. This can reveal patterns in valve performance and assist in preventive measures, ultimately enhancing operational efficiency.

| Feature | Description | Benefits | Maintenance Tips | Troubleshooting Tips |

|---|---|---|---|---|

| Sealing Mechanism | Integrates a bellows design for superior sealing | Prevents leakage, reducing maintenance costs | Regular inspection of bellows for signs of wear | Check for leaks and assess bellows integrity |

| Material Selection | Available in various materials like stainless steel, bronze | Corrosion resistance and enhanced durability | Clean regularly to prevent buildup of corrosive substances | Identify material compatibility with system fluids |

| Temperature Range | Suitable for high and low temperature applications | Versatile usage across different industries | Monitor operational temperature limits regularly | Inspect components for thermal fatigue |

| Pressure Rating | Capable of handling high pressure applications | Ensures reliability under pressure conditions | Check pressure ratings according to specifications | Correct any pressure anomalies promptly |