+86 19720579616

+86 19720579616

Zalo

Zalo

In the realm of industrial applications, selecting the appropriate valve can significantly impact operational efficiency and safety. Forged Steel Globe Valves, known for their durability and high-pressure capabilities, are often the preferred choice in various sectors, including oil and gas, chemical processing, and water treatment. According to the "Global Valve Market Report 2021," the forged steel valve segment is projected to grow at a compound annual growth rate (CAGR) of 6.2% over the next five years, driven by increasing demands for reliable and robust valve solutions. However, with myriad options available, choosing the right Forged Steel Globe Valve for your specific application necessitates a thorough understanding of your operational requirements and environmental conditions. This guide aims to provide essential insights and considerations to facilitate informed decisions when selecting the ideal valve for your needs.

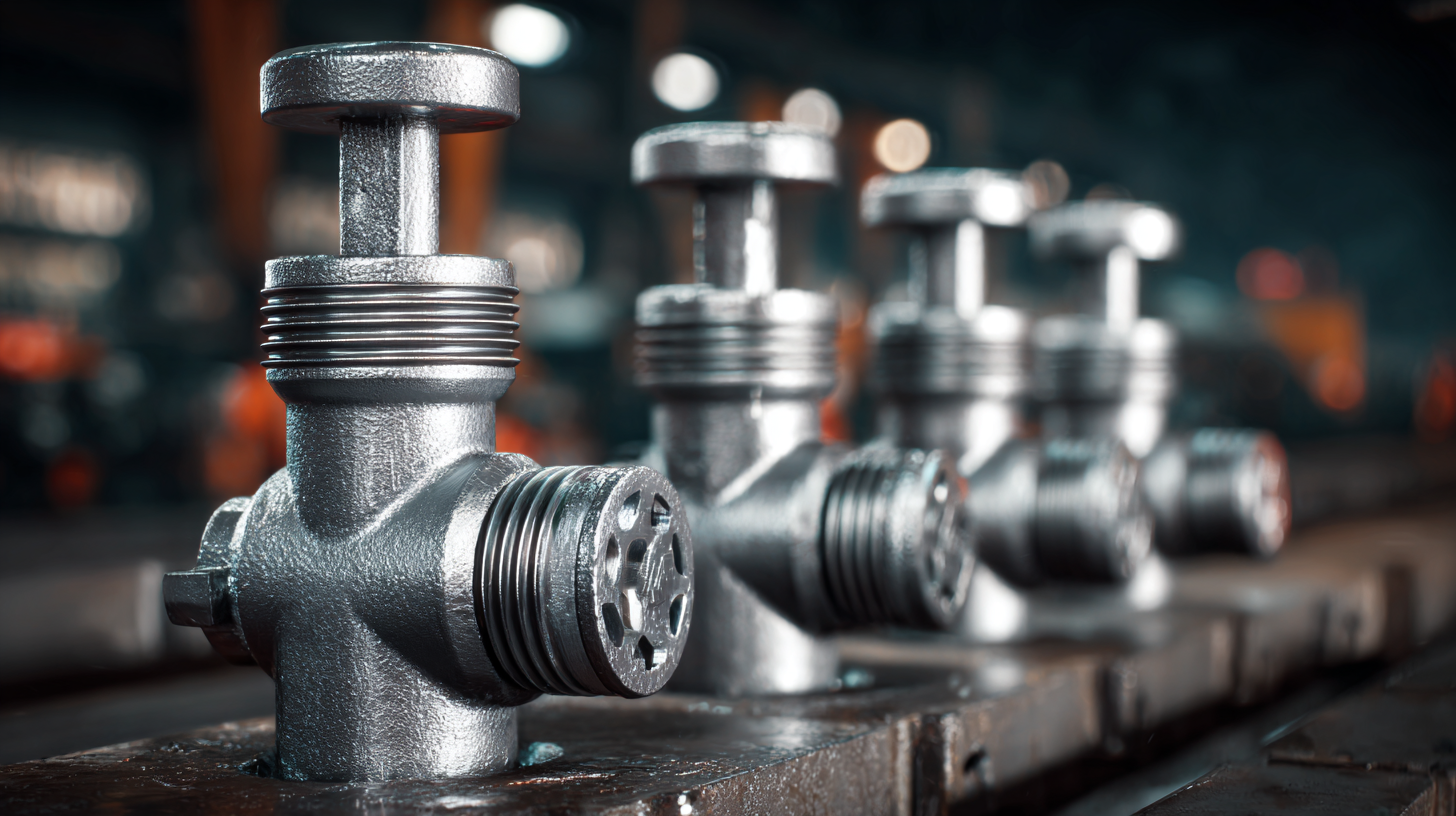

When selecting a forged steel globe valve for your specific application, understanding the key characteristics and specifications is crucial. Forged steel valves are known for their durability and strength, making them suitable for high-pressure and high-temperature environments. One of the primary factors to consider is the valve's size and pressure rating, which should align with your system's requirements to ensure optimal performance. Additionally, take note of the valve's end connections—flanged, threaded, or butt-weld—as these will impact how the valve integrates into your piping system.

Another essential characteristic to review is the valve's design and trim material. For instance, the use of stainless steel in the valve trim can enhance corrosion resistance, which is vital for applications involving hazardous or corrosive fluids. Furthermore, understanding the flow characteristics of the globe valve is important, as these valves are designed to offer excellent flow control but may cause pressure drops in certain conditions. Therefore, evaluating these specifications against your application needs will help you make an informed decision, ensuring that your valve delivers reliability and efficiency in your operations.

When selecting a forged steel globe valve for your specific application, one of the critical factors to evaluate is the pressure and temperature ratings. According to the American Society of Mechanical Engineers (ASME) standards, forged steel valves are typically rated to handle pressures ranging from 150 to 2500 psi, depending on the valve class. It is essential to match the valve's pressure rating with the system's operating conditions to ensure safety and reliability. For high-temperature applications, such as those found in oil and gas industries, valves can often operate effectively at temperatures exceeding 1000°F (538°C) when constructed from heat-resistant alloys.

In addition to pressure and temperature, understanding the appropriate material selection is vital for optimal performance. The ASTM A105 material specification for carbon steel forged valves indicates that they can maintain integrity under significant fluctuations in temperature and pressure. A recent industry report highlights that approximately 30% of valve failures in industrial settings can be attributed to mismatched pressure and temperature ratings. By carefully evaluating and choosing valves that align with both your operating conditions and the material properties, you can significantly enhance the longevity and effectiveness of your fluid control systems.

When selecting a forged steel globe valve for your application, the material and coating are crucial factors that significantly influence performance and longevity. The environment in which the valve will be used plays a pivotal role in determining the right composition. For instance, if the valve will be exposed to corrosive substances, choosing a material with higher corrosion resistance, such as stainless steel or specially alloyed steels, becomes essential. These materials provide enhanced durability, reducing the risk of leaks and failures over time.

In addition to the core materials, coatings can further protect forged steel globe valves from environmental stresses. Applying protective coatings such as epoxy, Teflon, or other chemical-resistant finishes helps shield the valve from abrasive agents, chemicals, and extreme temperatures. The choice of coating should align with both the specific chemicals handled in the system and the operational temperatures encountered. By carefully assessing your operational environment and selecting materials and coatings that meet these demanding requirements, you can ensure optimal performance and a longer lifespan for your globe valves.

| Material Type | Corrosion Resistance | Temperature Range (°C) | Coating Options | Application Suitability |

|---|---|---|---|---|

| Carbon Steel | Moderate | -29 to 350 | Epoxy Coating | General Purpose |

| Stainless Steel | High | -196 to 800 | PTFE Coating | Chemicals, Food Industry |

| Alloy Steel | Excellent | -40 to 600 | Ceramic Coating | High Pressure Applications |

| Ductile Iron | Moderate | -15 to 260 | Polyurethane Coating | Water and Wastewater |

When selecting a forged steel globe valve, the sizing and connection types play a crucial role in ensuring compatibility with your system. Proper sizing is essential to maintain the desired flow rates and pressure drops in your application. A valve that is too large can result in inefficient flow control, while a valve that is too small can lead to obstructions and potential system failure. Therefore, it is important to analyze the system's specifications to choose the right valve size that meets your operational requirements.

When it comes to connection types, there are various options available, such as flanged, threaded, or weld-end connections. It’s vital to match the valve's connection type with your existing piping to ensure a leak-free installation. Additionally, consider the material compatibility of the valve and the piping system, as mismatches can lead to corrosion and decreased lifespan of the components.

**Tips:** Always consult manufacturer guidelines and industry standards when determining the appropriate valve size and connection type. Conducting a thorough analysis of your system can help prevent costly downtimes. Lastly, consider future maintenance needs; opting for connection types that ease disassembly can save time and resources in the long run.

The following chart illustrates the distribution of different valve sizes and connection types commonly used in forged steel globe valves. This data helps in understanding compatibility with various piping systems and applications.

Forged steel globe valves are integral components in many industrial applications due to their durability and reliability. Commonly used in sectors such as oil and gas, power generation, and water treatment, these valves are designed to regulate flow efficiently. According to a report by Research and Markets, the global valve market, including forged steel types, is expected to reach $90 billion by 2027, driven largely by the rising demand in these key industries.

In the oil and gas sector, forged steel globe valves are crucial for controlling flow and pressure in pipelines. Their robust construction allows them to withstand high pressures and temperatures, making them ideal for processing environments. Furthermore, a study by TechSci Research suggests that the power generation industry, particularly in the Asia-Pacific region, will see significant growth, resulting in a corresponding increase in the demand for high-performance valves. As such, selecting the right forged steel globe valve for applications in these industries not only enhances operational efficiency but also ensures compliance with industry safety standards.