+86 19720579616

+86 19720579616

Zalo

Zalo

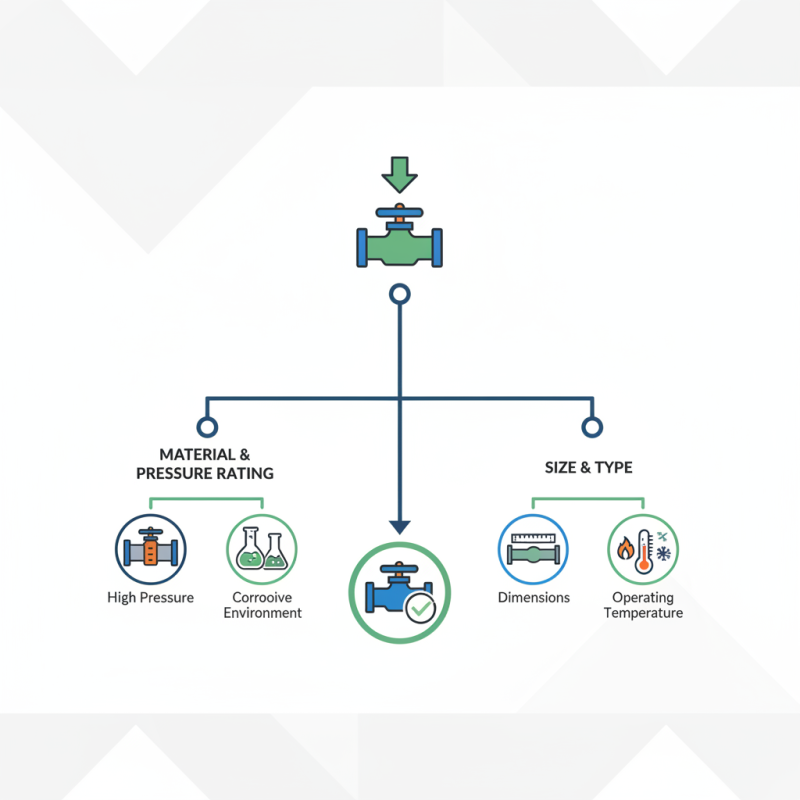

Choosing the right Din Globe Valves can be tricky. These valves are essential in many systems. They control fluid flow effectively. Each application may demand different specifications. Therefore, understanding your needs is crucial.

Consider the material and pressure ratings. Not all valves suit every environment. For example, a high-pressure system requires robust construction. Sometimes, people overlook these critical details. A wrong choice can lead to leaks. This could damage equipment and raise costs.

Think about the valve size and type. Selecting the right dimensions ensures a perfect fit. Additionally, the operating temperature is another factor to consider. It's often easy to forget these aspects. However, skimping on details can lead to frequent maintenance. Make sure to assess your requirements thoroughly before purchasing Din Globe Valves.

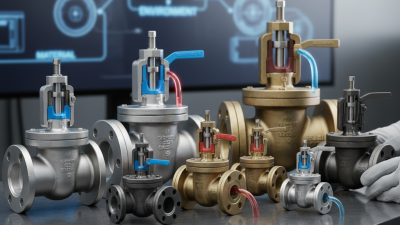

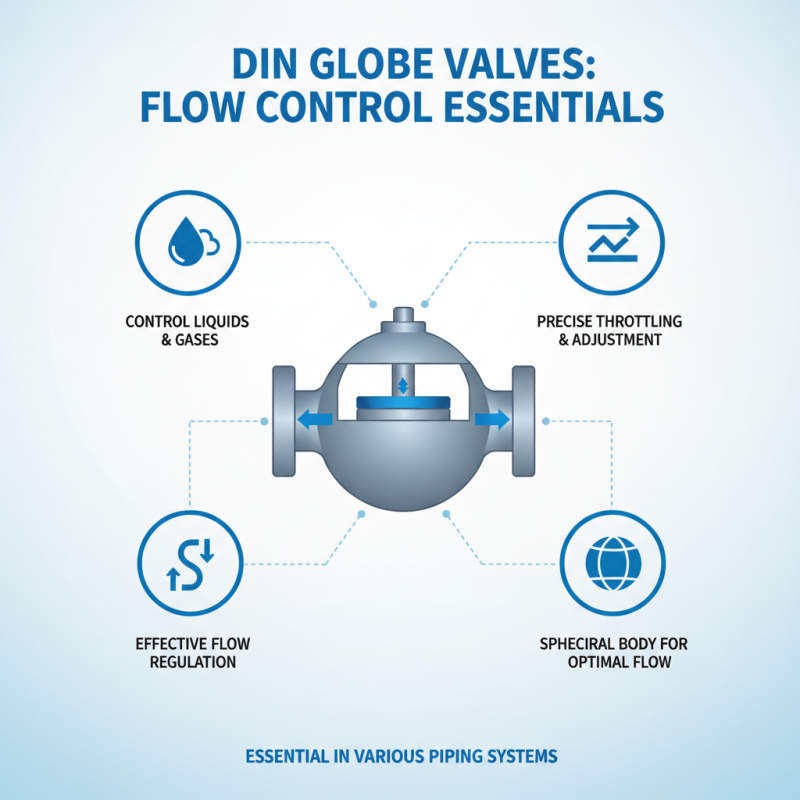

DIN globe valves are essential in various piping systems. They serve to control the flow of liquids and gases. The design allows for effective throttling. This enables precise adjustments to flow rates. The valve's body typically has a spherical shape, which gives it the name "globe." This shape helps facilitate flow control.

One key feature of DIN globe valves is their ability to handle high pressure. They are made from durable materials, ensuring longevity. Another important aspect is the seat design. A well-designed seat minimizes leakage, which is crucial in many applications. However, not all valves perform similarly. Some may face wear and tear sooner than expected. This could lead to less reliable operation.

Consider the type of system when selecting a valve. Not all applications require the same specifications. Sometimes, you may need to compromise between cost and quality. Make careful evaluations to avoid future issues. Think about maintenance as well. Access to the valve can impact your choice. Poor access makes repairs difficult. Understanding these details is beneficial in making an informed decision.

When selecting DIN globe valves, material types play a crucial role in performance and longevity. Common materials include stainless steel, carbon steel, and brass. Stainless steel is known for its excellent corrosion resistance. It can withstand harsh environments and high temperatures. However, cost can be a drawback. Prices for stainless steel valves can be 20% to 30% higher than carbon steel options, which limits their use in budget-constrained projects.

Carbon steel, on the other hand, is a more economical choice. This material suits many applications, especially in low-pressure systems. It is robust but may not resist corrosion as effectively as stainless steel. In a report by the American Society of Mechanical Engineers (ASME), 40% of valve failures resulted from corrosion-related issues, making material selection critical.

Brass is another alternative. This material is lightweight and offers good corrosion resistance. While brass valves are easier to install, they may not handle high pressures well. This can lead to failures in demanding applications. Evaluating the pros and cons of each material is essential for making informed decisions. Consider the specific requirements of your application. Often, the right choice isn’t straightforward. Each material presents unique challenges and benefits.

| Material Type | Pros | Cons | Typical Applications |

|---|---|---|---|

| Brass | Corrosion resistant, good thermal conductivity | Limited high-temperature capabilities | Water, gas, oil applications |

| Stainless Steel | High strength, good corrosion resistance | Costly, may gall under certain conditions | Chemical, food processing applications |

| Ductile Iron | High durability, good tensile strength | Lower corrosion resistance than stainless | Water treatment, industrial uses |

| PVC | Lightweight, resistant to many chemicals | Brittle in cold temperatures | Water, chemical transport |

| Bronze | Excellent corrosion resistance, durable | More expensive than brass | Marine applications, plumbing |

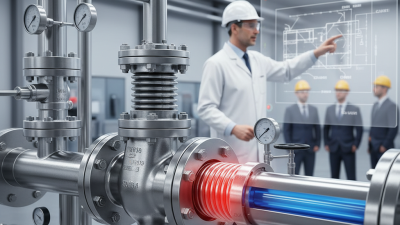

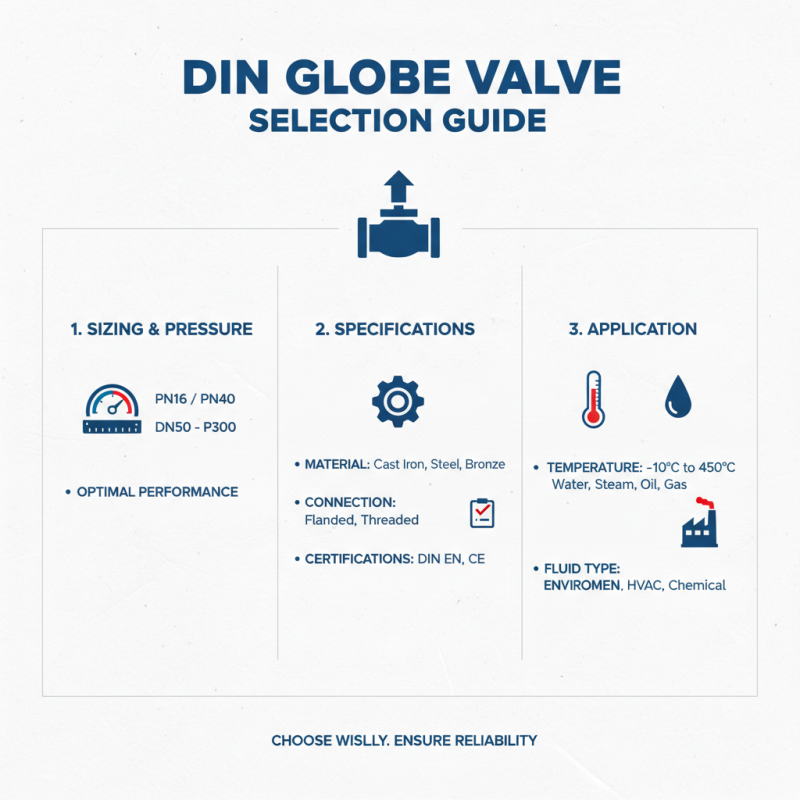

Choosing the right DIN globe valves involves understanding sizing and pressure ratings. Specifications play a crucial role in ensuring optimal performance. Consider the application environment carefully. The temperature and fluid type can significantly affect valve choice.

When sizing a valve, it's essential to match it to the piping system. Measure the pipe diameter accurately. Oversized valves can lead to turbulent flow. This can cause pressure loss and inefficient operation. On the other hand, undersized valves might not handle required flow rates, leading to system failures.

Tip: Always consult with system engineers during the selection process. Their experience can guide you towards making informed decisions.

Pressure ratings are equally important. Valves must withstand the maximum expected pressure. Ignoring this can result in catastrophic failures. A mismatched valve can compromise safety.

Tip: Review historical data for similar systems. Analyze previous failures to avoid repeating mistakes. Remember, making the right choice now saves time and money later.

When selecting din globe valves, application considerations are crucial. Different environments demand specific features. A valve suitable for water might not work for gas. For example, high-temperature applications require valves made of robust materials. Consider the medium’s characteristics before making a choice.

Think about the installation space. Some setups lack room for large valves. Compact designs are often necessary in these cases. Also, assess the frequency of use. Frequently operated valves may need quick responses. Actuated options may be ideal here. However, if used infrequently, manual valves could suffice.

Reflect on maintenance requirements as well. Some valves need regular upkeep, which can be a hassle. Easy-to-service options can save time and costs. Always plan for potential issues. Will the valve lose efficiency over time? Addressing these questions leads to the best selection for your needs.

Din globe valves are essential for fluid control in various industries. Proper maintenance is vital for their longevity and optimal performance. According to industry reports, regular servicing can extend valve life by up to 30%. Inspections should focus on seats, seals, and leak points. Small leaks can escalate if not addressed.

To ensure optimal valve performance, lubrication is key. Use the right grease regularly. Over-lubrication can attract dirt, while under-lubrication leads to wear. The American Society of Mechanical Engineers (ASME) recommends a bi-annual maintenance schedule. However, some facilities wait too long. This leads to unforeseen costs and performance issues.

Another common mistake is neglecting the environment. Corrosive substances quickly degrade valve components. Surrounding conditions must be monitored. Installing a protective barrier can help. Maintenance logs are essential for tracking issues and repairs. Data shows that facilities with organized records reduce downtime by 25%. Regular evaluation and reflection on these practices lead to better reliability.