+86 19720579616

+86 19720579616

Zalo

Zalo

When it comes to selecting the right components for industrial applications, the choice of valves is critical, and among them, API 602 forged steel valves stand out for their durability and reliability. These valves are designed to meet high standards of performance in various environments, making them a preferred option for many engineers and procurement specialists. The importance of choosing the right API 602 forged steel valves cannot be overstated, as they play a vital role in controlling the flow of fluids, ensuring operational efficiency and safety.

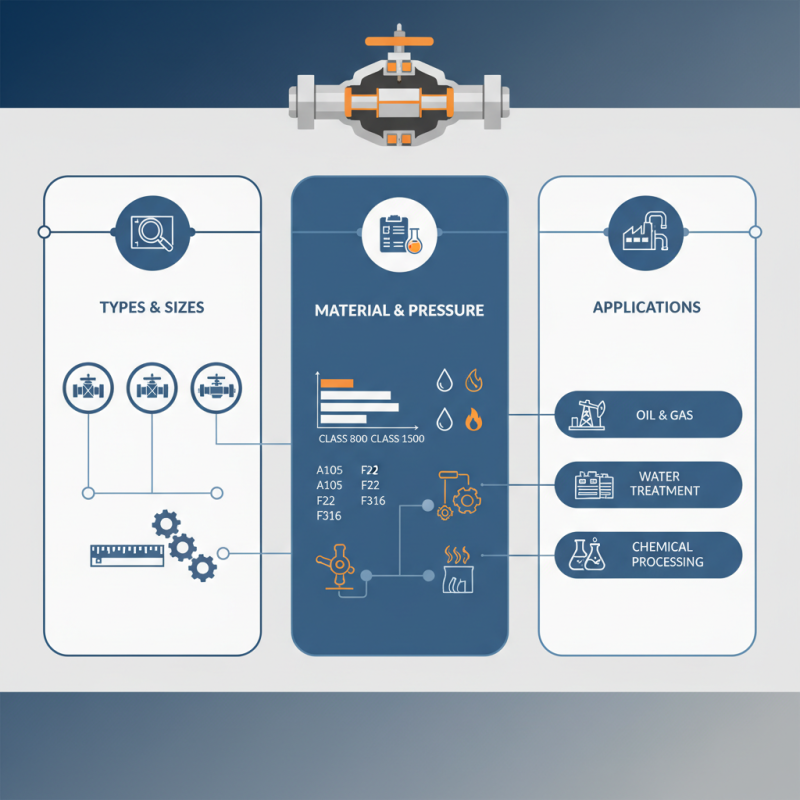

In this guide, we will explore the key factors to consider when selecting API 602 forged steel valves for your specific needs. From understanding the different types and sizes available to evaluating material specifications and pressure ratings, making an informed decision is imperative to achieving optimal system performance. Whether you are involved in oil and gas, water treatment, or chemical processing, the right valve choice can significantly impact your project's success and sustainability. Let’s delve into the essential elements that will help you make the best selection for your application.

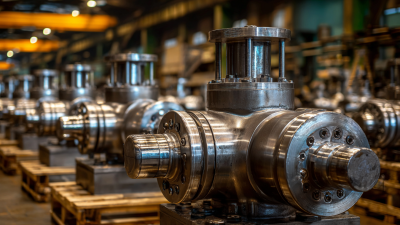

API 602 forged steel valves are essential components in industrial applications, renowned for their durability and performance. These valves are designed to handle high-pressure and high-temperature environments, making them suitable for oil and gas, chemical processing, and power generation sectors. One of the key features of API 602 valves is their construction from high-grade forged steel, which enhances their integrity and resistance to severe service conditions. According to a report by the Market Research Future, the demand for forged steel valves is expected to grow at a CAGR of 5.2% from 2021 to 2028, underscoring their importance in various industries.

In addition to their robust construction, API 602 valves feature a compact design that allows for easier installation and maintenance. This layout not only maximizes space efficiency but also reduces the overall weight of the system, leading to cost-effective solutions for manufacturers and operators alike. The valves are versatile, available in different sizes and pressure ratings, providing operators with flexibility in their applications. Furthermore, a study by the American Society of Mechanical Engineers indicates that the reliability of forged steel valves can lead to a reduction in maintenance costs by as much as 30%, thereby enhancing operational efficiency and ensuring consistent performance in critical systems.

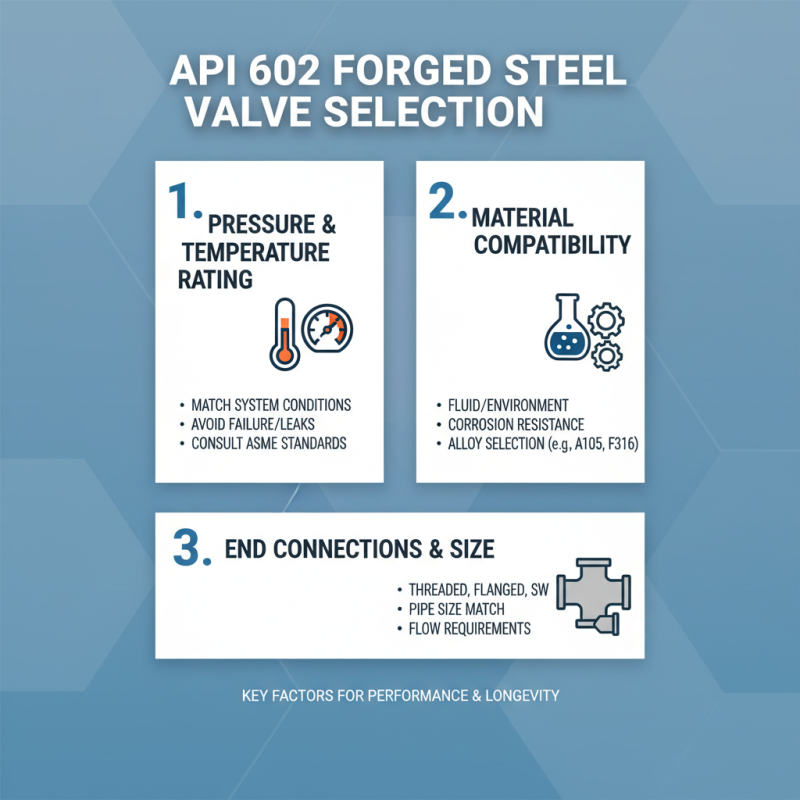

When selecting API 602 forged steel valves, there are several key factors to consider that can significantly impact performance and longevity. First and foremost is the pressure and temperature rating of the valve. It is crucial to ensure that the valve's specifications match the operating conditions of your system, as inadequate ratings can lead to valve failure, leaks, or even catastrophic accidents. Be sure to refer to the relevant ASME standards when assessing these requirements, as they clearly outline the acceptable limits for various applications.

Another important consideration is the material composition of the forged steel valve. Different applications may require specific material grades to withstand corrosion, thermal stress, and wear. For instance, high-quality alloys may be necessary for environments with corrosive fluids, while standard carbon steel valves might suffice for less demanding applications. Additionally, evaluate the valve design, such as the type of sealing mechanism and flow characteristics, to ensure it aligns with your system's operational needs. Ultimately, thorough evaluation of these factors will help you select the right API 602 forged steel valve, ensuring not only compatibility but also efficiency and reliability in your operations.

When selecting API 602 forged steel valves, understanding the material specifications is crucial as they significantly influence valve performance and longevity.

Forged steel, known for its high strength and durability, is typically used in high-pressure and high-temperature applications. The choice of alloy and the heat treatment processes can greatly alter the mechanical properties of the valve. For example, valves made from higher carbon content steel will generally offer increased hardness, which can enhance wear resistance, but may also lead to reduced ductility. Therefore, balancing these properties to match the specific service conditions is essential.

In addition to strength and durability, corrosion resistance is another vital aspect influenced by material specifications. Selecting the appropriate alloy can help mitigate issues related to chemical exposure in various environments. Stainless steel variants, for instance, may be favored in corrosive environments due to their ability to withstand oxidation and scaling, extending the valve's operational life. Understanding the operating environment and the potential effects of different materials can guide engineers in choosing the right valve for their specific needs while optimizing performance and reliability.

API 602 forged steel valves are crucial components utilized in a variety of industries due to their durability and reliability. They are commonly found in applications involving high-pressure and high-temperature environments, making them ideal for the oil and gas sector, power generation, and chemical processing. In these industries, these valves are used to control the flow of liquids and gases, ensuring operational efficiency and safety. Their robust construction allows them to withstand extreme conditions, which is why they are often the preferred choice for critical applications.

Moreover, API 602 forged steel valves are also employed in water treatment plants and HVAC systems. In water treatment facilities, these valves help regulate the flow of water and chemical additives, ensuring the purification process runs smoothly. In HVAC applications, they play a vital role in controlling the temperature and flow of heating and cooling systems, enhancing energy efficiency. Understanding the specific requirements of each application is essential for selecting the right valve.

Tips: When choosing API 602 forged steel valves for your specific needs, consider factors such as the pressure and temperature ratings, the materials of construction, and the type of media that will flow through the valve. Conducting a thorough analysis of your operational environment will help you make an informed decision that ensures reliability and longevity.

When selecting the right API 602 forged steel valves for your specific requirements, it is essential to conduct a comparative analysis of leading manufacturers and their products. Each manufacturer offers unique features and benefits, allowing users to make informed decisions based on performance, durability, and pricing. Key aspects to consider include the valve's material specifications, pressure ratings, and the design characteristics that align with your application’s specific demands.

**Tips:** When comparing different manufacturers, focus on the following criteria: certifications, warranty policies, customer reviews, and the availability of technical support. This information can greatly influence your overall satisfaction and the long-term viability of the valves in your operations.

Moreover, evaluating the availability of spare parts and service options is crucial. Some manufacturers provide extensive support and quick availability of components, which can save time and reduce downtime when maintenance is required. By prioritizing these factors, you can ensure that your choice of forged steel valves meets both your immediate and future needs effectively.

| Manufacturer | Product Type | Size Range (inches) | Pressure Rating (Class) | Material | End Connection Type |

|---|---|---|---|---|---|

| A | Ball Valve | 1/2 - 6 | 150 - 2500 | A105 | SW, BW |

| B | Globe Valve | 1 - 8 | 150 - 600 | A216 WCB | FL, SW |

| C | Check Valve | 2 - 10 | 150 - 1500 | A350 LF2 | BW, FL |

| D | Gate Valve | 2 - 12 | 150 - 3000 | A105N | SW, BW |