+86 19720579616

+86 19720579616

Zalo

Zalo

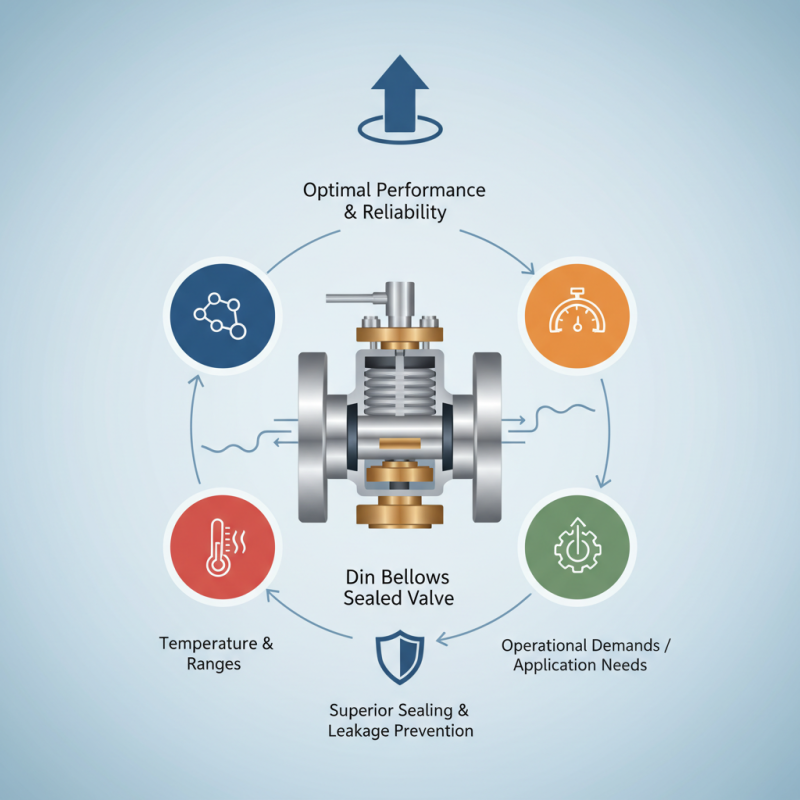

In the world of industrial valves, making the right choice is critical for ensuring optimal performance and reliability. When it comes to Din Bellows Sealed Valves, experts emphasize the importance of selecting the right components to achieve the desired outcomes in various applications. Dr. Emily Carter, a leading authority in valve engineering, once stated, "The effectiveness of Din Bellows Sealed Valves lies not only in their design but also in understanding the operational demands they will face." This insight helps underscore the need for careful consideration when choosing these valves.

Din Bellows Sealed Valves are specifically designed to provide superior sealing and prevent leakage, making them an ideal choice for industries that require stringent safety and performance standards. As the demand for reliable sealing solutions continues to grow, selecting the appropriate valve type becomes critical. Evaluating factors such as material compatibility, pressure ratings, and temperature ranges can significantly impact the valve's longevity and efficiency. By understanding these parameters and the specific needs of the application, you can ensure that your choice of Din Bellows Sealed Valves will yield optimal results throughout their operational life.

Din bellows sealed valves are specialized components designed to provide a high level of sealing integrity in various applications. Their unique construction features a flexible bellows element that protects the valve's sealing surfaces from exposure to environmental factors, such as dust, moisture, and corrosive substances. This design is particularly beneficial in industries where maintaining strict cleanliness or preventing leaks is crucial, such as pharmaceuticals, food processing, and chemical manufacturing. By ensuring minimal contamination and optimal performance, these valves can extend the longevity of the entire system.

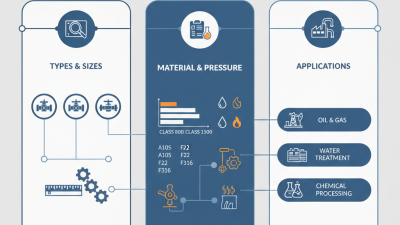

When selecting Din bellows sealed valves, consider factors such as the media being handled, pressure and temperature conditions, and the specific application requirements. Valves should be chosen based on the compatibility of the bellows material with the fluid to avoid degradation over time.

Tips: Always verify the pressure ratings and temperature limits of the bellows sealed valves to ensure they match your system's specifications. Additionally, examining the valve's maintenance requirements can help maintain optimal performance over time. For applications involving abrasive materials, opting for valves with durable bellows can enhance reliability and reduce the frequency of replacements.

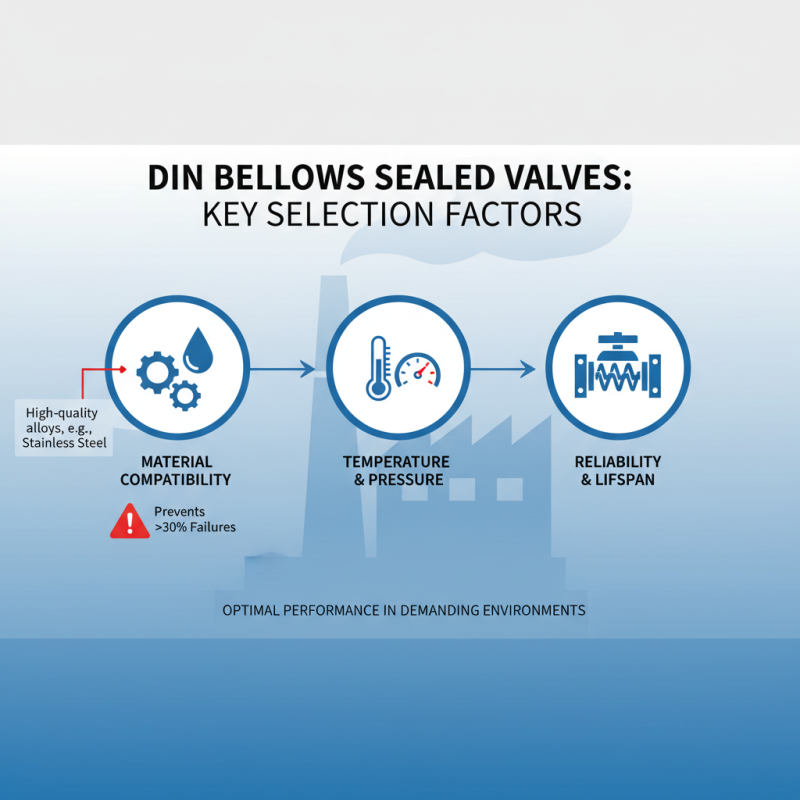

When selecting DIN bellows sealed valves, several critical factors must be considered to ensure optimal performance and reliability. First, the material compatibility with the media being handled is essential. Valves made from high-quality alloys or corrosion-resistant materials, such as stainless steel, can significantly enhance performance in demanding environments, where factors like temperature and pressure may vary. Industry reports indicate that over 30% of valve failures are attributed to material incompatibility, emphasizing the importance of selecting the right materials based on application requirements.

Another significant factor is the pressure and temperature ratings of the valves. It is vital to ensure that the chosen DIN bellows sealed valve meets or exceeds the operational pressure and temperature limits of the system it is utilized in. According to a recent study published by the Valve Manufacturers Association, valves that operate outside their rated conditions can experience a failure rate increase of up to 40%. Additionally, the installation and maintenance practices should also be considered, as proper handling and periodic checks can extend the life of these components. Overall, careful consideration of these key factors will enhance the performance and reliability of DIN bellows sealed valves in various applications.

When evaluating the quality and durability of Din bellows sealed valves, it is essential to consider material construction and design features. The choice of materials used in the manufacturing process significantly impacts the valve's resistance to corrosion, high temperatures, and pressure variations. Valves constructed with high-grade materials, such as stainless steel or specialized alloys, offer enhanced durability, extending their operational lifespan in harsh environments. Additionally, the design of the bellows seal itself is critical; it should provide an effective barrier against leakage while maintaining flexibility to accommodate movements caused by pressure changes.

Another important aspect to assess is the valve's testing and certification standards. High-quality Din bellows sealed valves undergo rigorous testing procedures to ensure they meet industry specifications for performance and reliability. It is advisable to review certifications that indicate compliance with relevant safety and performance standards, which can give users greater confidence in the valve's reliability. Furthermore, examining user reviews and case studies can provide valuable insights into the real-world performance of the valves, helping to determine their long-term effectiveness in various applications. By focusing on these critical factors, users can make informed decisions that ensure optimal performance and reliability from their Din bellows sealed valves.

To ensure the long-term performance of din bellows sealed valves, regular maintenance is crucial. One key aspect of maintaining these valves is to conduct routine inspections for any signs of wear or damage. Checking the integrity of the bellows themselves is essential, as they serve as the primary barrier against fluid leakage. Any visible cracks or deformations may indicate that the valve needs immediate attention. Additionally, verifying that all connections and fittings are secure can help prevent leaks and ensure optimal functionality.

Another important maintenance tip is to clean the valve regularly, particularly if it operates in a dusty or corrosive environment. Accumulated debris can hinder the movement of internal components, leading to increased wear and a higher likelihood of malfunction. Furthermore, lubricating moving parts, when applicable, can enhance their performance and prolong the life of the valve. It’s also advisable to adhere to a scheduled maintenance plan that includes systematic checks and adjustments based on the specific operating conditions of the valve. This proactive approach will help maintain reliability and efficiency, ultimately reducing costly downtime and repairs.

When selecting DIN bellows sealed valves, avoiding common mistakes can significantly impact both performance and reliability. One prevalent error is underestimating the required pressure and temperature ratings. According to a study by the Valve Manufacturers Association, 30% of valve failures in industrial applications can be traced back to miscalculations regarding these critical specifications. Ensuring that the selected valve meets or exceeds the operational demands helps to mitigate risks such as leaks and premature failures, ultimately enhancing system integrity.

Another frequent oversight is neglecting the valve material compatibility with the process media. A report from the American Society of Mechanical Engineers highlights that improper material selection contributes to approximately 25% of maintenance issues in valve installations. It's essential to consider factors like corrosion resistance and thermal stability based on the specific fluids or gases the valve will encounter. Ignoring these aspects can lead to costly downtimes and repairs, so thorough assessment of material properties is vital in the decision-making process.

Ultimately, understanding the operational environment and avoiding pitfalls like underestimating specifications and overlooking material suitability can lead to better performance and longer service life for DIN bellows sealed valves. By prioritizing these considerations, users can optimize their valve selection process and enhance overall system reliability.

| Dimension | Value | Common Mistakes | Recommended Solutions |

|---|---|---|---|

| Material Compatibility | Stainless Steel, PTFE | Ignoring chemical compatibility | Consult compatibility charts |

| Temperature Range | -20°C to 120°C | Not considering temp limits | Select valves with suitable ratings |

| Pressure Rating | PN 16, PN 25 | Underestimating pressure needs | Evaluate system pressure requirements |

| Size | DN 15 to DN 100 | Choosing incorrect size | Verify with piping dimensions |

| Actuation Type | Manual, Electric, Pneumatic | Not matching actuation with application | Analyze operation requirements |