+86 19720579616

+86 19720579616

Zalo

Zalo

Selecting the right Api Bellows Sealed Globe Valves is crucial for any industrial application. According to industry expert John Smith, “The proper choice of bellows valves can significantly impact system efficiency.” These valves offer unique advantages, including leak prevention and long service life. However, many users overlook vital selection factors.

When considering Api Bellows Sealed Globe Valves, one must focus on material compatibility, pressure ratings, and temperature controls. Many manufacturers fail to disclose critical specifications. This oversight can lead to operational inefficiencies. Be vigilant; not all valves meet the same standards. Examine your application’s specific needs carefully.

In practice, choosing the wrong valve can result in costly downtime or safety issues. While it may seem like a minor detail, improper valve selection can lead to significant setbacks. Consider consulting with a knowledgeable expert. Their insights can guide you to make informed choices. Your operational success may depend on it.

When selecting API bellows sealed globe valves, several factors should be carefully considered to ensure reliability and performance. Material compatibility is critical. The valves must be made from materials that can withstand the specific media they will control. A report by the Valve Manufacturers Association highlighted that improper material choices lead to failures in 30% of tested valves.

Another important aspect is the sizing of the valve. Proper sizing ensures optimal flow and minimizes pressure drops. This can directly impact system efficiency. Industry data shows that incorrectly sized valves can result in energy losses of up to 20%. It's essential to calculate flow requirements accurately before making a selection.

When selecting bellows sealed globe valves, understanding their design and functionality is essential. These valves utilize a flexible metal bellows for sealing, which prevents leakage. The bellows act as a barrier between the medium and the environment. This design is crucial in harsh conditions. The materials used for bellows are often stainless steel, ensuring durability and resistance to corrosion.

The operation of these valves is straightforward. When the handle turns, the disc moves up or down to control fluid flow. However, it's important to consider the application. Bellows sealed valves are ideal for systems with high purity requirements. Yet, they may not be suitable for all scenarios, especially those involving extreme temperatures.

Another consideration is maintenance. While bellows sealed valves require less upkeep than traditional valves, they can still face issues. Misalignment or corrosion over time can lead to failures. Users should regularly inspect these valves to ensure their proper function. Even the best products can fall short if not maintained correctly. Selecting the right bellows sealed globe valves takes careful thought and evaluation to avoid potential pitfalls.

When selecting api bellows sealed globe valves, material selection plays a crucial role. The right material enhances both longevity and performance. Common materials include stainless steel and brass. Each has its unique benefits and limitations. Stainless steel is corrosion-resistant and ideal for harsh environments. However, it can be costlier than alternatives. Brass offers good durability but may not withstand extreme conditions.

Consider the application of the valves. High temperatures require specialized materials. Materials like Inconel or Monel could be necessary in such cases. These are more expensive, yet their performance can justify the cost. It's important to weigh the technical requirements against budget constraints. Sometimes, opting for a less expensive material could lead to failures down the line.

Look closely at maintenance aspects too. Some materials require more upkeep than others. A valve that needs frequent checks may not be practical for every scenario. Think about how easily a material can be repaired or replaced. It’s a balancing act. One should avoid rushing the decision. Each material option presents its trade-offs that need careful consideration.

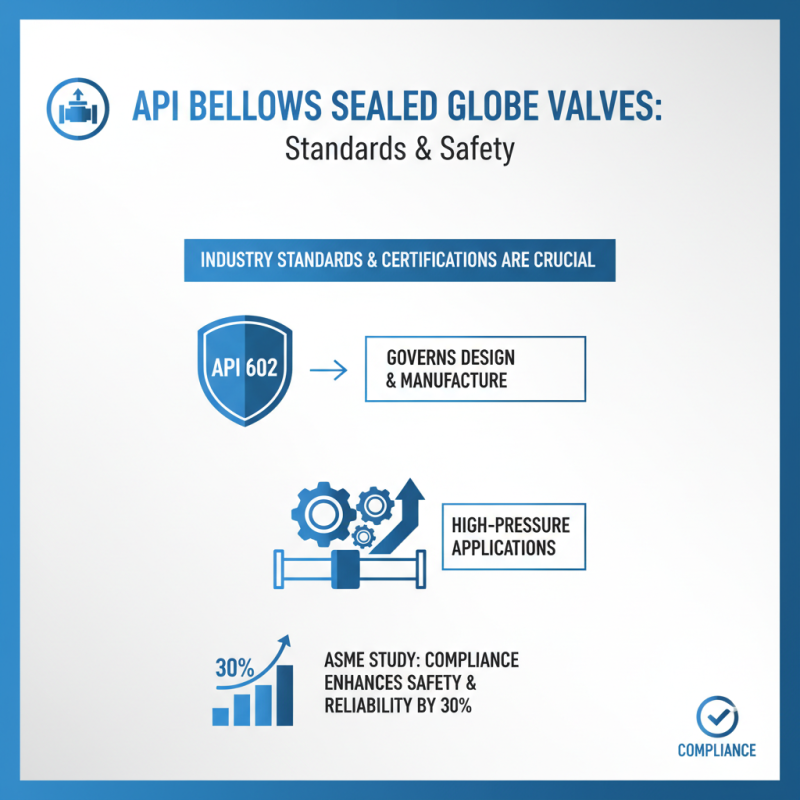

When selecting API bellows sealed globe valves, understanding industry standards and certifications is crucial. The API 602 standard specifically governs the design and manufacture of these valves. Compliance ensures they can handle high-pressure applications. A study by the American Society of Mechanical Engineers (ASME) highlights that compliance can enhance safety and reliability by over 30%.

Moreover, the importance of certifications cannot be understated. ISO 9001 certification indicates a quality management system in place. This often results in superior product longevity and performance. Interestingly, a report from the Global Valve Industry noted that over 40% of failures could be attributed to non-compliance with these standards.

Despite this, companies often overlook certification details. Many assume all valves meet minimum requirements. This can lead to costly failures in critical applications. Therefore, evaluating certifications is not just a tick-box exercise; it’s a necessity. Ensuring that selected valves meet API and ISO standards can minimize risks and improve operational efficiency.

When selecting API bellows sealed globe valves, understanding pressure and temperature ratings is crucial. The right choice directly impacts operational efficiency. For example, valves rated for higher temperatures (over 300°C) may use specific alloys for durability. This ensures they withstand thermal expansion without compromising seal integrity.

Tip: Always check the valve's pressure rating. A common standard is ANSI/ASME, which provides specifications for pressure classes. Knowing this helps avoid premature failures. For example, a valve rated at 150 psi may not perform well in high-pressure applications.

Consider what your system requires. Each application has unique challenges, such as fluid type and environmental conditions. Incorrect rating can lead to leaks or valve failure. Remember, not all applications require high-temperature ratings. Sometimes, standard ratings work fine.

Tip: Use real-time data when making choices. Industry reports indicate that improper valve selection leads to around 30% of maintenance issues in chemical processing plants. Awareness of these factors enhances longevity and dependability. Choose wisely to avoid costly mistakes.

| Parameter | Importance | Typical Value Range | Recommended Practices |

|---|---|---|---|

| Pressure Rating | Critical for leak prevention | 150 to 2500 psi | Select based on system requirements |

| Temperature Rating | Affects material choice | -20°F to 400°F | Ensure compatibility with fluids |

| Material | Durability and corrosion resistance | Stainless Steel, Carbon Steel | Choose based on fluid properties |

| Size | Flow capacity determination | 1/2" to 12" | Match to pipeline dimensions |

| End Connection Type | Compatibility with piping | Flanged, Welded, Threaded | Assess existing infrastructure |