+86 19720579616

+86 19720579616

Zalo

Zalo

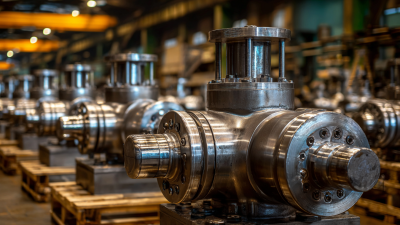

In the realm of industrial valves, the choice of the right equipment can significantly influence operational efficiency and safety. According to a recent report by the Global Valve Market Study, the demand for API Bellows Sealed Globe Valves has surged, attributed to their superior sealing capabilities and reliability in high-pressure applications. These valves are engineered to prevent leaks and ensure minimal maintenance, making them ideal for critical processes in industries such as oil and gas, chemical, and power generation.

With projections indicating a market growth rate of 5.2% annually through 2026, understanding the specifications and optimal use cases for API Bellows Sealed Globe Valves is essential for engineers and procurement specialists. This guide will explore essential criteria for selecting the most suitable valve for your specific application, helping you to make an informed and strategic decision.

API bellows sealed globe valves are critical components in various industries, offering a reliable solution for controlling fluid flow while minimizing the risk of leakage. Understanding the different types and standards of these valves is essential for selecting the right one for your application. The primary types include standard bellows sealed valves, which feature a bellows assembly that prevents fluid leakage, and extended bellows valves, designed for high-temperature and high-pressure applications. Additionally, there are variations depending on the body material, size, and pressure rating, each serving specific operational requirements.

When considering standards, the American Petroleum Institute (API) provides guidelines to ensure the quality and reliability of bellows sealed globe valves. Adhering to these standards is crucial for safety and performance, particularly in the oil and gas sector. Factors such as the materials used in construction, the design specifications, and testing protocols are outlined in API publications, offering manufacturers and end-users a framework to evaluate valve performance. Ultimately, recognizing the distinct types and standards associated with API bellows sealed globe valves will aid in making informed decisions that align with operational needs and regulatory compliance.

When selecting an API bellows sealed globe valve, evaluating material compatibility is crucial to ensure optimal performance and longevity. Different applications require different materials to withstand various conditions such as temperature, pressure, and corrosive environments. For instance, if the valve will be exposed to aggressive chemicals, using materials resistant to those substances is essential. Materials like stainless steel, alloys, and certain plastics may be necessary, depending on the specific requirements of the application.

In addition to chemical compatibility, considerations such as temperature ratings and pressure class must also be taken into account. The bellows must be constructed from materials that can handle the expected thermal expansion and contraction without losing integrity. It's important to refer to manufacturer specifications and industry standards to choose the right materials that will serve the functional needs of the valve while also ensuring safety and reliability in operation. Always consult with suppliers or industry professionals to align material choices with application demands.

| Material | Temperature Range (°C) | Pressure Rating (MPa) | Application Examples | Corrosion Resistance |

|---|---|---|---|---|

| Stainless Steel | -50 to 120 | 1.6 | Water, Oil, Gas | Good |

| Carbon Steel | -20 to 80 | 2.5 | Water, Steam | Moderate |

| Bronze | -30 to 150 | 1.0 | Hydraulic Systems, Water | Excellent |

| PTFE Lined | -50 to 200 | 1.0 | Chemical Processing | Very Good |

| Alloy Steel | -50 to 450 | 2.4 | Power Generation | Good |

When selecting an API bellows sealed globe valve, understanding

pressure and temperature ratings is crucial for ensuring

optimal performance. According to the American National Standards Institute (ANSI), valves

must be rated for the maximum pressure they will encounter in operation. For instance, a typical bellows sealed

globe valve may have a pressure rating of up to 300 psi, depending on the size

and materials used. It's essential to match these ratings with your specific application to avoid failure

and downtime.

Temperature ratings also play a significant role. The

American Petroleum Institute (API) specifies that valves must

withstand specific temperatures, often ranging from -20°F to 450°F based on the

material composition. For example, stainless steel materials can typically handle higher temperatures compared

to carbon steel. Furthermore, a recent industry report highlighted that improper

temperature ratings could lead to valve deterioration, causing leaks or malfunctions in critical systems.

Thus, always consult the manufacturers' specifications and

industry standards to ensure that the selected valve meets

both pressure and temperature requirements for your application.

When selecting the right API bellows sealed globe valve for your application, a crucial consideration is the flow coefficient (Cv). The Cv value of a valve indicates how easily fluid can flow through it, and understanding this parameter is vital for efficient system design. A higher Cv means that the valve can allow more flow at a given pressure drop, which is essential for applications requiring precise flow control. Recent studies suggest that optimizing the Cv value can significantly enhance energy efficiency in systems. For example, a well-designed valve can lead to up to a 20% reduction in energy consumption in fluid transport systems, particularly in HVAC applications under varying operational faults and changing climate scenarios.

Moreover, using regression analysis can provide insights into how the Cv values of various valve designs affect overall system performance, ensuring they meet the specific requirements of diverse applications. Data from lifecycle assessments indicate that systems designed with properly sized and configured valves can achieve better emissions reductions, similar to those observed in projects evaluating hydrogen and electrical propulsion technologies. Thus, when choosing a globe valve, it is paramount to assess the Cv to ensure that your system operates efficiently and sustainably, minimizing both energy use and environmental impact.

The following chart illustrates the flow coefficient (Cv) of various API bellows sealed globe valves. The Cv value indicates the valve's capacity to allow fluid flow, which aids in selecting the appropriate valve for specific applications.

When selecting an API bellows sealed globe valve, understanding the maintenance requirements is crucial for ensuring both longevity and reliability in your applications. These valves are designed to provide excellent sealing capabilities, minimizing leakage of fluids, but regular maintenance is essential to preserve their performance. Implementing a consistent maintenance schedule that includes inspections, cleaning, and lubrication can significantly reduce wear and prevent potential failures, ultimately extending the valve's lifespan.

Moreover, it's important to tailor maintenance practices to specific operational conditions. For instance, valves exposed to high temperatures or aggressive chemicals may require more frequent checks to identify any signs of deterioration or corrosion. Additionally, keeping an eye on the seals and bellows for signs of wear can preemptively address issues before they lead to costly downtimes. By fostering a proactive maintenance culture, operators can enhance the reliability of the API bellows sealed globe valve, ensuring it functions effectively in demanding environments.