+86 19720579616

+86 19720579616

Zalo

Zalo

In the evolving landscape of industrial valve technology, the selection of the right components is crucial for ensuring optimal performance and longevity. As highlighted by industry expert Dr.Emily Carter, a renowned authority in fluid dynamics, "The right choice of valves not only prevents leaks but also enhances system efficiency." This insight is particularly relevant when considering Api Bellows Sealed Gate Valves, which are designed to provide effective sealing and reduce the risk of contamination in critical applications.

The design and functionality of Api Bellows Sealed Gate Valves make them a preferred option across various sectors, from chemical processing to oil and gas. These valves utilize a unique bellows seal that not only protects the valve rod from exposure to harmful substances but also eliminates the need for packing adjustments, thereby minimizing maintenance efforts. As industries strive for greater sustainability and operational efficiency, understanding the attributes of Api Bellows Sealed Gate Valves becomes essential for engineers and procurement specialists alike.

In this guide, we will delve into key considerations for choosing Api Bellows Sealed Gate Valves, exploring factors such as material selection, pressure ratings, and application requirements. By gaining a deeper understanding of these parameters, professionals can ensure that they make informed decisions that enhance system reliability and performance.

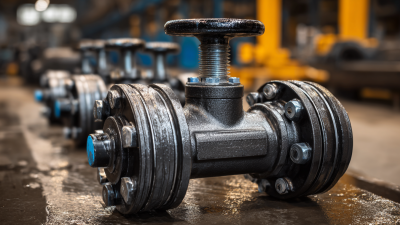

API bellows sealed gate valves are crucial components in various industries, providing a reliable solution for fluid control while ensuring minimal leakage. Understanding the basics of these valves is essential for achieving optimal performance. The design of bellows sealed gate valves incorporates flexible metal bellows, which effectively isolate the valve’s fluid from the actuator components. This unique feature prevents contamination and allows for a tight seal, making them ideal for applications where leakage could lead to significant operational hazards or environmental concerns.

When selecting API bellows sealed gate valves, one must consider several key factors that influence their performance. First and foremost is the material construction, as it should be compatible with the media being handled. Additionally, the operation pressure and temperature ratings play a critical role in ensuring the valve can withstand the specific conditions of the application. Proper sizing and configuration are also vital, as they affect flow rates and the overall efficiency of the system. By understanding these fundamentals, operators can make informed decisions that enhance the longevity and reliability of their fluid control systems.

When selecting bellows sealed gate valves, several key factors must be taken into account to ensure optimal performance. First and foremost, the material of the valve is crucial, as it must be compatible with the fluid being handled. Common materials include stainless steel, brass, and various alloys, which should be chosen based on the chemical properties and temperature conditions of the application. Additionally, the bellows material itself should be resistant to corrosion and wear, thereby enhancing the longevity and reliability of the valve.

Secondly, the design and size of the bellows sealed gate valve play a significant role in its functionality. The flow rate required for the specific application will dictate the valve size, and improper sizing can lead to inefficiencies or operational failures. Furthermore, the design of the valve should facilitate smooth operation, minimizing the risk of clogging or pressure drops during flow. It is also essential to evaluate the pressure rating and temperature tolerance to ensure the valve can operate effectively within its intended environment without compromise.

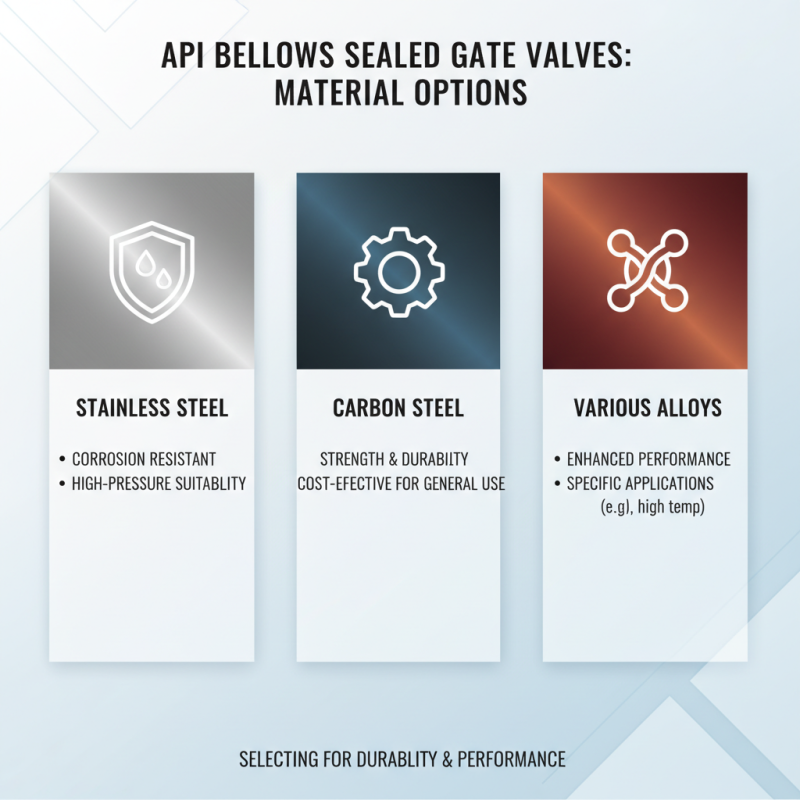

When selecting API bellows sealed gate valves, evaluating material options is crucial for ensuring both durability and performance. The primary materials commonly used in the construction of these valves include stainless steel, carbon steel, and various alloys. Stainless steel is favored for its resistance to corrosion and ability to maintain structural integrity under high-pressure conditions. This makes it particularly suitable for applications in harsh environments or with corrosive media.

In addition to stainless steel, carbon steel remains a popular choice due to its strength and cost-effectiveness. However, carbon steel may require additional coatings or treatments to enhance its resistance to oxidation and corrosion. Alloys can also be considered for specialized applications, as they can offer enhanced mechanical properties and better performance at elevated temperatures or pressures. By carefully assessing the environmental conditions and media characteristics, engineers can select the most appropriate materials that not only meet performance requirements but also extend the lifespan of the valves in demanding applications. This thoughtful consideration of materials will ensure optimal functionality and reliability of the API bellows sealed gate valves in various industrial settings.

When it comes to installing API bellows sealed gate valves, following best practices ensures optimal functionality and longevity. First and foremost, it is essential to prepare the installation site thoroughly. This includes inspecting the valve and associated piping for any debris or damage. Proper alignment during installation is crucial; misaligned valves can lead to increased wear and tear, potentially causing leaks or operational failure. Always use the correct tools and techniques when tightening bolts, as overtightening can damage the valve or affect its performance.

Additionally, attention to seal integrity is critical when installing bellows sealed gate valves. Ensure that the sealing surfaces are clean and free of contaminants to prevent leaks. The use of appropriate gaskets or sealing compounds recommended for the specific application can further enhance performance. It's also advisable to conduct a pressure test post-installation to verify that there are no leaks and that the valve operates smoothly under the expected operating conditions. By adhering to these best practices, you can significantly improve the reliability and efficiency of your bellows sealed gate valves in any application.

Maintaining the integrity and efficiency of bellows sealed gate valves is crucial for optimal performance in various industrial applications. According to a recent industry report from the Valves Technology Consortium, regular maintenance can extend the lifespan of these critical components by up to 30%. Key maintenance practices include routine inspections, proper lubrication, and monitoring for signs of wear or corrosion, which are essential given that these valves often operate under extreme conditions.

One effective strategy is implementing a proactive maintenance schedule that involves detailed assessments of the bellows seal. This seal is pivotal in preventing leaks, and any signs of damage should be addressed immediately to avoid costly downtime. Furthermore, cleaning the valve and surrounding area regularly can prevent debris buildup that may lead to operational failures.

Research indicates that valves subjected to a rigorous maintenance program not only demonstrate enhanced reliability but also contribute to overall system efficiency, resulting in significant cost savings over time.