+86 19720579616

+86 19720579616

Zalo

Zalo

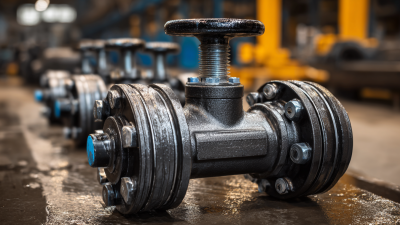

When selecting Din Bellows Sealed Gate Valves for your project, understanding specific requirements is vital. These valves offer excellent sealing properties, reducing the risk of leakage. Their design features a bellows that prevents contamination, making them ideal for various applications.

Consider the operational environment. Will the valve be exposed to high temperatures or corrosive materials? The right choice should endure such conditions. There are various sizes and pressure ratings available. It’s crucial to match them to your system to ensure efficient operation.

However, not all Din Bellows Sealed Gate Valves are created equal. Some may not perform as expected. Researching the manufacturer’s reputation can prevent potential issues. Pay attention to user reviews and industry standards. A well-informed decision can lead to improved project outcomes.

Choosing the right din bellows sealed gate valves for your project requires careful consideration of several key factors. Begin with the material compatibility. Ensure that the valve material aligns with the fluid being handled. This prevents corrosion and enhances longevity.

Pressure ratings are another essential consideration. Verify that the valve can withstand the pressure of your application. High-pressure systems demand valves with robust construction. A mismatch here can lead to failures and costly leaks.

Tip: Always consult manufacturer guidelines. These often have insights on appropriate usage. Don't skip this step; it could be the difference between success and failure.

Think about size requirements. A valve that is too large or small can disrupt flow rates. Measure your piping carefully. If you're unsure, ask for expert assistance.

Another critical factor is maintenance ease. Inaccessible valves can incur higher operational costs. Regular maintenance is key to performance. Plan for it in your project timeline.

Tip: Create a checklist for installation. This can help avoid mistakes that may later require corrections. Valves are vital components. A little extra effort in selection pays off.

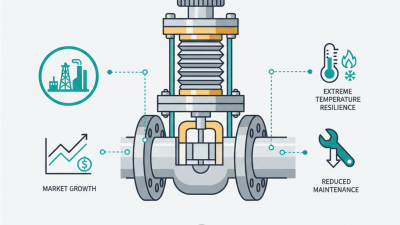

Bellows sealing in gate valves offers a unique solution for preventing leaks. It achieves this by utilizing a flexible bellows element, which can absorb movement and maintain a seal. This is particularly important in applications where fluid leakage could lead to safety hazards or environmental concerns. A recent industry report highlighted that around 30% of valve failures are due to leakage, making reliable sealing methods essential.

The effectiveness of bellows-sealed gate valves is evident in their applications across various sectors. For instance, in chemical processing, where corrosive substances are common, these valves provide stability and durability. They can handle pressures up to 150 psi, significantly reducing the risk of material fatigue. Additionally, with proper maintenance, these valves can last longer than traditional sealing methods. However, some users have reported issues with installation precision. Improperly installed bellows might lead to premature failure.

Moreover, understanding the specific requirements of your project is crucial. Factors like temperature fluctuations and pressure changes can impact sealing performance. A well-documented case showed that failing to account for such conditions resulted in increased maintenance costs. Always assess the operational environment and consider its dynamic nature when selecting bellows sealed gate valves.

When selecting materials for DIN bellows sealed gate valves, several key options stand out. The choice of material greatly influences valve performance and longevity. Common materials include carbon steel, stainless steel, and special alloys. Each option has its advantages. For example, stainless steel offers excellent corrosion resistance. It is suitable for harsh environments. Carbon steel is often used for its cost-effectiveness but may lack durability in corrosive applications.

Consider the specific application requirements. For instance, high-temperature environments may necessitate the use of special alloys. According to a recent industry report, about 30% of valve failures are due to material incompatibility with process fluids. This emphasizes the importance of careful material selection. Sometimes, the wrong choice leads to costly leaks or valve failures. Depending on the application, using materials like duplex stainless steel may reduce maintenance needs significantly.

Also, analyze factors such as pressure ratings and temperature limits. Using the wrong material can limit the valve's performance. A study showed that valves with improperly selected materials could reduce system efficiency by 20%. This highlights the need for thorough assessment and expert advice when choosing materials. Every project has unique requirements. Customizing choices based on these needs is essential for optimal performance and safety.

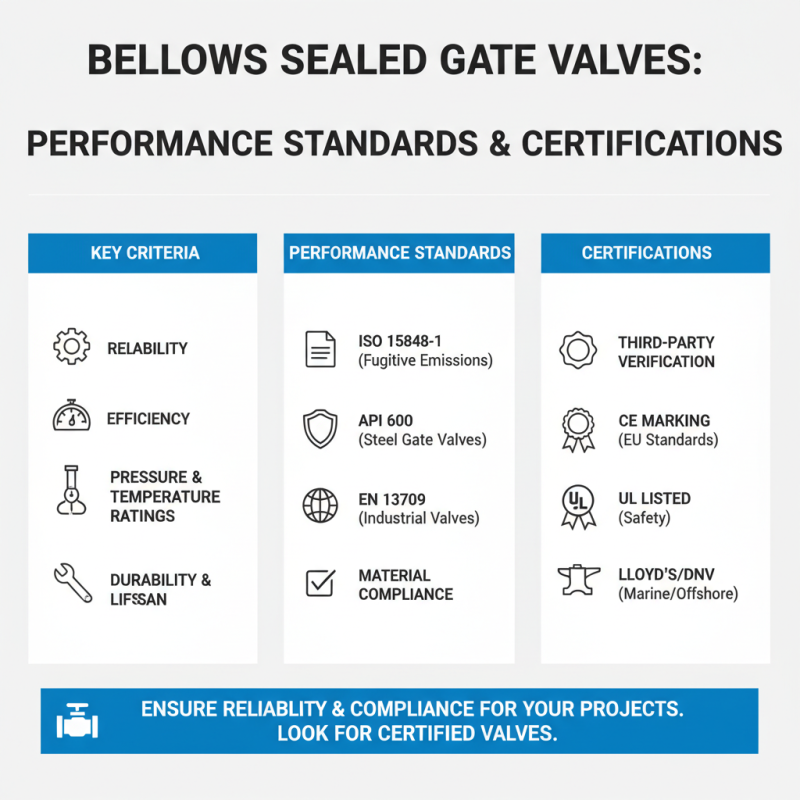

When selecting bellows sealed gate valves for your project, understanding performance standards is crucial. These valves must meet specific criteria to ensure reliability and efficiency. Look for certifications from recognized organizations. They provide assurance that the valve performs under various conditions.

A well-certified gate valve minimizes risks. Quality checks are key. Ensure that the valves conform to industry standards like API or ISO. This guarantees that they can handle pressure and temperature variations. Remember, a valve's lifespan can be affected by its design and material. Choosing materials suited for the application is essential.

However, not all valves are equal. Some may not perform as expected under certain conditions. It's part of the design process to consider potential failures. A deeper look into testing procedures reveals room for improvement. Ensuring every aspect of the gate valve is up to snuff can save future headaches. Selecting the right gate valve is about more than just choosing the first option available.

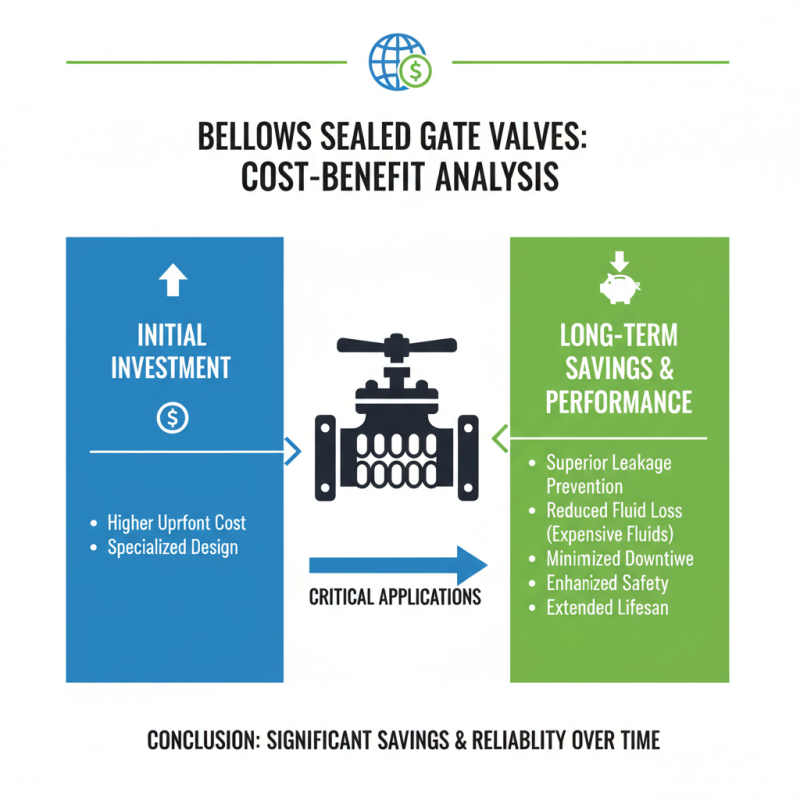

When considering bellows sealed gate valves, a cost-benefit analysis is essential. These valves offer superior performance in critical applications. Their design minimizes leakage. This is crucial in preventing the loss of expensive fluids. The initial investment may seem high, but the long-term savings can be significant.

Maintenance costs are often lower with bellows sealed valves. They provide enhanced durability and reliability. Companies can save on repair expenses over time. Additionally, reducing leakage helps in environmental compliance. This can prevent costly fines.

However, it’s important to evaluate specific project needs. Not every application requires the benefits a bellows sealed valve brings. Understanding your system's demands is key. Sometimes, simpler valve designs may suffice. Balancing upfront costs with potential long-term savings requires careful consideration. Each project is unique, prompting necessary reflection on the best choice.