+86 19720579616

+86 19720579616

Zalo

Zalo

Din Gate Valves play a crucial role in various industrial applications. According to a report from Market Research Future, the global gate valve market is expected to reach $8 billion by 2025. This growth highlights the increasing demand for reliable performance and durability in fluid control systems.

These valves are designed to provide a tight sealing when fully closed, minimizing leakage. However, users must recognize that not all Din Gate Valves are of the same quality. A 2020 survey revealed that around 30% of industries reported valve failures due to substandard materials. This calls for careful consideration when selecting valves for specific applications.

Moreover, durability is not merely about initial functionality. It also pertains to long-term resistance to wear and corrosion. Regular maintenance and proper selection can lead to improved lifespan. Yet, users often overlook the importance of sourcing valves from reputable manufacturers. Understanding the trade-offs and the conditions in which these valves operate is essential for ensuring maximum efficiency.

DIN gate valves are essential components in various industries. They are used to control the flow of fluids in pipes. Their design allows for minimal pressure drop, making them effective for numerous applications. According to a market report by Grand View Research, the global valve market is expected to reach $90 billion by 2027, indicating strong growth. This trend highlights the increasing reliance on durable valve solutions.

In power plants, chemical processes, and water treatment facilities, DIN gate valves play a pivotal role. They are known for their reliable performance. A technical study by Engineering Toolbox reveals that the correct valve selection can enhance system efficiency by up to 30%. This efficiency is crucial but often overlooked during the selection process.

Tips: Ensure you assess the specific application before choosing a valve. Consider factors such as pressure, temperature, and fluid type. It is also worth noting that materials matter. Opt for corrosion-resistant options for harsh environments. Regular maintenance can prevent costly downtimes. Neglecting this may lead to performance issues.

When selecting a durable DIN gate valve, focus on the materials used. High-quality materials like stainless steel ensure strength and reliability. The valve's internal components should resist corrosion and wear. This maximizes its lifespan in various applications, from water systems to industrial processes. Valves made of brass or carbon steel can also provide good performance, but their durability may vary.

Moreover, pay attention to the design features. A well-designed gate valve has a smooth operation that minimizes friction. Look for seals that prevent leaks over time. The handle should provide good grip and allow for easy manipulation. Testing the valve under different pressures can help identify any weaknesses. Thin walls may save material costs but can compromise durability.

Lastly, consider maintenance requirements. Some valves are easier to maintain than others. A design that allows easy access to internal components is essential for long-term use. Remember, neglecting maintenance can lead to larger issues down the line. It's crucial to ensure that the chosen valve is both easy to operate and service. This balance contributes to performance and ensures reliability.

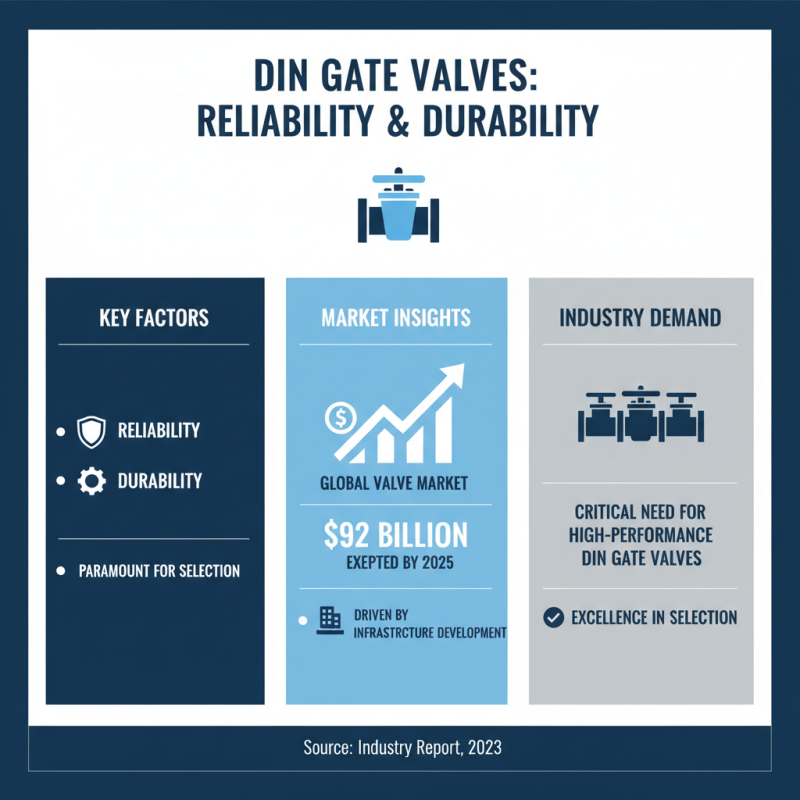

When selecting DIN gate valves, reliability and durability are paramount. The market offers numerous options, but certain brands consistently excel. A recent industry report indicates that the global valve market is expected to reach $92 billion by 2025, driven largely by infrastructure development. This growth highlights the critical demand for high-performance DIN gate valves.

Tips: Always check for compliance with industry standards. Look for valves with certifications to ensure quality.

Top manufacturers invest in innovative materials to enhance performance. For instance, using stainless steel can improve corrosion resistance. However, some valves may not perform well under extreme conditions. It's essential to consider application specifics when making a choice.

Tips: Review installation guidelines carefully to avoid future issues. Proper installation can extend service life significantly.

While many options exist, not every valve will meet every need. Sometimes, cost-saving measures can lead to performance trade-offs. Be cautious when prioritizing budget over quality. Seek reliable data to inform your purchase decisions.

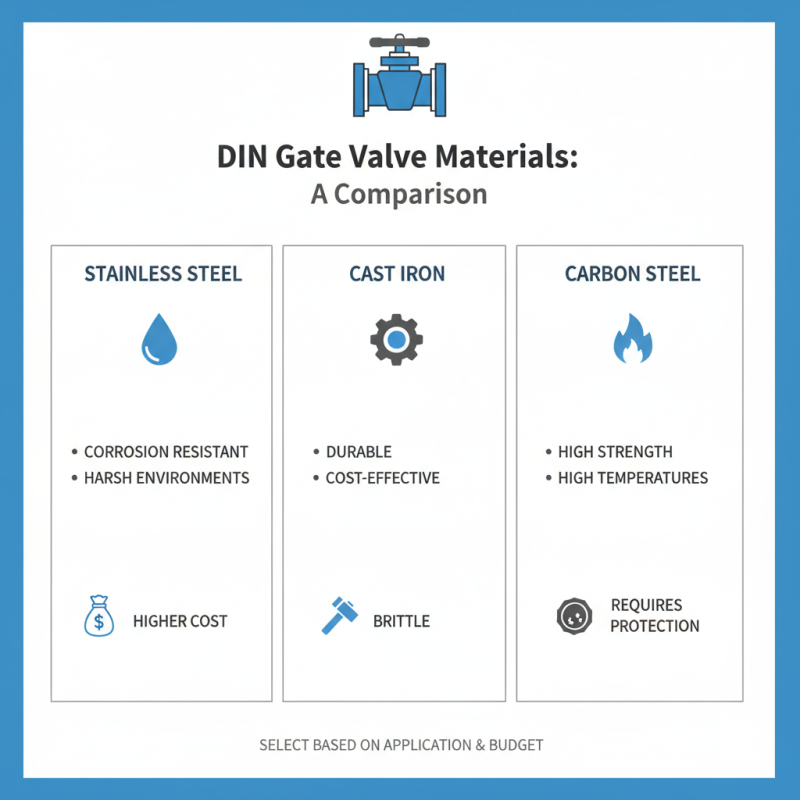

When selecting DIN gate valves, the material used in their construction is crucial. Typical materials include stainless steel, cast iron, and carbon steel. Each material offers various advantages and challenges. For instance, stainless steel is known for its corrosion resistance, making it suitable for harsh environments. However, it can be more expensive, leading to cost and budget considerations.

Cast iron is often used for its durability and ability to withstand high pressure. Yet, it can be brittle, which raises concerns about cracking under extreme conditions. According to a recent industry report, nearly 30% of gate valve failures occur due to material fatigue. This fact highlights the importance of selecting the right material for your specific application.

Tips: Consider the operating environment. If corrosion is a risk, stainless steel may be your best choice. Regular inspections can help identify issues early. Choosing the wrong material can lead to costly downtime and replacements. Always consult with a professional about your options.

DIN gate valves are essential for regulating flow in various industries. Proper maintenance is crucial to ensure their longevity and reliable performance. Regular inspections can help identify early signs of wear and tear. According to a recent industry report, valves that undergo consistent maintenance can outlast their counterparts by up to 30%.

Tips: Keep valves free from debris. Dirt can cause them to malfunction. A simple cleaning routine can save costly repairs. Ensure that seals are checked often. Worn seals can lead to leaks and operational inefficiencies.

It's vital to monitor the operating conditions. Extreme pressure or temperatures can stress the valve materials. Surprisingly, many users ignore this factor, leading to premature failures. Regularly review installation settings to maintain optimal performance. Remember, a small oversight can result in significant issues. Investing time in maintenance pays off in enhanced durability.

This chart illustrates the performance ratings of various aspects of DIN gate valves, highlighting their reliability and durability based on material quality, flow efficiency, pressure rating, temperature resistance, and overall durability.