+86 19720579616

+86 19720579616

Zalo

Zalo

In the ever-evolving landscape of industrial applications, the choice of valve technology is paramount to ensuring efficiency and reliability.

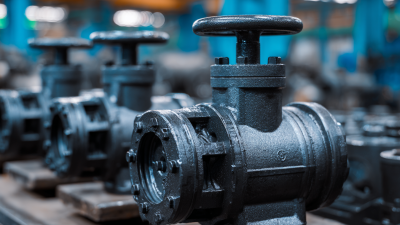

Din Gate Valves, renowned for their robust construction and exceptional performance, have emerged as a preferred solution in various sectors.

According to John Smith, an expert with over 20 years of experience in valve technology,

"The use of Din Gate Valves significantly enhances operational integrity and reduces maintenance costs."

His insights underscore the importance of selecting the right valve type to meet specific industrial demands.

Din Gate Valves, renowned for their robust construction and exceptional performance, have emerged as a preferred solution in various sectors.

According to John Smith, an expert with over 20 years of experience in valve technology,

"The use of Din Gate Valves significantly enhances operational integrity and reduces maintenance costs."

His insights underscore the importance of selecting the right valve type to meet specific industrial demands.

As industries face increasing pressure to optimize productivity while maintaining safety and environmental standards, understanding the benefits of Din Gate Valves becomes crucial. From their unparalleled sealing capabilities to their suitability for high-pressure applications, these valves offer distinctive advantages that can transform operational workflows.

The following sections will delve into the top five benefits of utilizing Din Gate Valves, illustrating why they are not just a choice, but an essential component for modern industrial systems. Whether in chemical processing, water management, or power generation, Din Gate Valves have carved a niche for themselves, ultimately contributing to the overall success of industrial operations.

Din gate valves are a crucial component in industrial applications, offering enhanced flow control that leads to optimal performance. One of the primary advantages of using these valves is their ability to provide a tight seal, which minimizes leakage and maintains the integrity of the system. This is particularly important in industries where the precision of flow management is critical, such as in chemical processing and water treatment. By effectively regulating the flow of fluids, din gate valves help ensure that operations run smoothly and efficiently.

Moreover, din gate valves are designed for high durability and reliability under various pressure conditions. Their structure allows for quick opening and closing, which helps in maintaining the desired flow rates without significant pressure drops. This responsiveness not only enhances operational efficiency but also reduces the risk of equipment wear and tear over time. With their superior flow control capabilities, din gate valves prove to be an invaluable asset in managing complex industrial processes, ultimately contributing to improved productivity and reduced operational costs.

DIN gate valves are renowned for their durability and longevity, making them an ideal choice for various industrial applications. One of the primary advantages of these valves is their robust construction, which allows them to withstand extreme conditions, including high pressures and corrosive environments. This inherent strength results in a significantly extended service life compared to alternatives. In fact, recent studies have shown that components designed with durability in mind, such as structural silicone glazing sealants, can last for over 50 years. This kind of longevity in industrial products not only reduces maintenance costs but also enhances safety and reliability in operations.

Furthermore, the design and materials used in DIN gate valves contribute to their exceptional performance. They typically feature precision-engineered components that minimize wear and tear over time. This contrasts sharply with less robust alternatives that may require frequent replacements, ultimately driving up operational costs. With the increasing demand for sustainable and long-lasting solutions in industrial settings, the use of DIN gate valves is a strategic choice that aligns with the need for efficiency and durability in pipeline systems and other critical infrastructure. Thus, opting for these valves ensures that industries can rely on consistent functionality and reduced downtime, leading to more efficient operations in the long run.

When it comes to industrial applications, Din gate valves stand out for their cost-efficiency in long-term use. These valves are designed to minimize flow resistance, which greatly reduces energy consumption and operational costs. By providing a reliable shut-off solution, they help prevent leaks and minimize the need for frequent maintenance, allowing businesses to allocate their resources more effectively.

Tips for Maximizing Cost-Efficiency with Din Gate Valves:

When it comes to industrial applications, the choice of valve plays a critical role in operational efficiency and maintenance. One significant advantage of DIN gate valves is their ease of maintenance, which simplifies repairs and minimizes downtime. According to a report by the Valves and Actuators Market Research conducted by MarketsandMarkets, around 30% of maintenance costs in industrial settings can be attributed to valve maintenance. The straightforward design of DIN gate valves allows technicians to quickly access internal components, reducing the time and labor required for repairs.

Additionally, DIN gate valves are known for their durability and reliability. A study from the International Journal of Engineering and Technology highlights that the robust construction of these valves can withstand rigorous operating conditions, leading to fewer failures and extended service intervals. This translates to a lower total cost of ownership, as facilities can expect a decrease in the frequency of maintenance activities. With the industry average downtime costing facilities upwards of $250,000 per hour, having valves that are easier to service can lead to substantial financial savings and ensure smoother operations in demanding environments.

DIN gate valves are renowned for their versatility across various industrial applications, making them essential in modern fluid management systems. Their design allows for efficient flow regulation and isolation, particularly in environments where space and material compatibility are critical. According to a report by the Global Valve Market Research, the adoption of gate valves in sectors such as oil and gas, water treatment, and power generation is projected to grow by approximately 5% annually, underscoring their significance in crucial operations.

One of the standout features of DIN gate valves is their robust construction, which accommodates a wide range of pressures and temperatures. This adaptability not only enhances durability but also minimizes maintenance needs, thereby reducing operational costs. Specific studies have shown that industries utilizing DIN gate valves report a reduction in downtime by 20%, as these valves can withstand harsh conditions better than their counterparts. Moreover, their compatibility with various materials, including corrosion-resistant alloys, further broadens their application scope, making them ideal for chemical processing and pharmaceutical manufacturing.