+86 19720579616

+86 19720579616

Zalo

Zalo

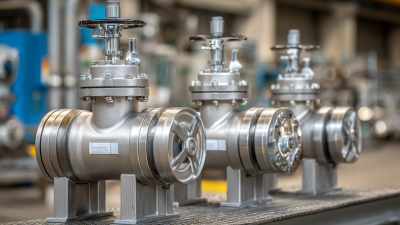

In the realm of industrial applications, the choice of valves plays a crucial role in ensuring efficiency, safety, and reliability. Among various types of valves, Api Bellows Sealed Globe Valves stand out due to their unique design and functionality.

These valves are engineered to provide a tight seal, preventing leakage of fluids and gases, which is vital in high-pressure and high-temperature environments. Understanding the benefits of Api Bellows Sealed Globe Valves is essential for engineers and procurement specialists looking to optimize their operations.

These valves are engineered to provide a tight seal, preventing leakage of fluids and gases, which is vital in high-pressure and high-temperature environments. Understanding the benefits of Api Bellows Sealed Globe Valves is essential for engineers and procurement specialists looking to optimize their operations.

This guide delves into the significant advantages offered by these valves, including enhanced durability, reduced maintenance needs, and improved performance in controlling flow. By exploring how to effectively implement Api Bellows Sealed Globe Valves in industrial settings, stakeholders can make informed decisions that lead to operational excellence and greater safety standards in their facilities.

When selecting the right API bellows sealed globe valve for industrial applications, it is essential to consider several key factors that influence performance and compatibility. First, evaluating the specific service conditions—such as temperature, pressure, and the nature of the fluid—will help identify the best material and design features needed. API bellows sealed globe valves are particularly beneficial for high-pressure applications, as their design minimizes the risk of leakage, thus enhancing safety and reducing maintenance costs.

Additionally, consider the size and flow requirements of your system. A properly sized valve ensures optimal flow characteristics and efficiency. It's also crucial to pay attention to the installation requirements and accessibility for maintenance when selecting a valve.

Collaborating with experienced suppliers can provide insights into customization options and help in making informed decisions that align with your operational goals, ultimately contributing to improved reliability and performance of your industrial systems.

Bellows sealed globe valves have become increasingly popular in industrial applications due to their unique design features that enhance performance and reliability. Unlike traditional valves, bellows sealed globe valves utilize a flexible metal bellow to create a leak-proof seal, preventing the escape of fluids and gases. This feature is particularly beneficial in industries where corrosive substances or high-pressure conditions are prevalent, as it reduces the risk of contamination and ensures safe operation. According to a recent industry report, the global market for valve sealing systems is projected to grow at a CAGR of 5.6% from 2022 to 2028, highlighting the increasing demand for efficient and secure valve solutions.

In addition to their sealing capabilities, bellows sealed globe valves are designed for easy operation and maintenance. The construction allows for minimal turbulence and pressure drop across the valve, optimizing flow efficiency. Recent innovations in valve technology, such as the introduction of new series of ball valves, have also contributed to the industry's drive towards improved functionality and ease of use. Industry analysts emphasize that adopting these advanced valve designs can result in a 30% increase in operational efficiency, influencing both project cost savings and environmental sustainability efforts within various sectors. These aspects underscore the importance of integrating bellows sealed globe valves into modern industrial systems.

API Bellows Sealed Globe Valves are increasingly recognized for their effectiveness in various industrial applications. These valves are designed to prevent leakage by utilizing a bellows seal that isolates the media from the atmosphere. This feature is particularly beneficial in systems dealing with hazardous or corrosive substances, as it minimizes the risk of contamination and enhances workplace safety. The ability to maintain a tight seal reduces maintenance costs and downtime, making these valves a practical choice for industries such as oil and gas, chemical processing, and power generation.

When considering the advantages of API Bellows Sealed Globe Valves, several key factors come into play. They offer excellent thermal and pressure resistance, which is critical in high-demand environments. The robust design not only prolongs the lifespan of the valve but also ensures optimal performance under varying operational conditions. Furthermore, their compact structure allows for easy installation and maintenance, which can lead to significant savings in both time and resources.

**Tip:** Always ensure that the bellows are regularly inspected for wear and tear. This proactive approach can prevent unexpected failures and enhance the longevity of the valve in your operations. Regular maintenance checks should also include verifying the integrity of the seals and ensuring that the valve functions smoothly under its designated pressure and temperature ranges.

| Feature | Description | Advantages |

|---|---|---|

| Sealing Mechanism | Utilizes a bellows sealing mechanism to prevent leakage. | Provides high reliability and reduces environmental hazards. |

| Material Options | Available in various materials like stainless steel and carbon steel. | Enhances durability and corrosion resistance for different applications. |

| Temperature Range | Operates effectively at extreme temperatures. | Suitable for diverse industrial processes. |

| Pressure Control | Designed for high-pressure applications. | Ensures efficient operation under challenging conditions. |

| Maintenance | Requires minimal maintenance compared to traditional valves. | Reduces operational costs and downtime. |

When installing API bellows sealed globe valves, adhering to best practices is crucial for ensuring efficient valve performance in industrial applications. First, verify that the installation environment is suitable, avoiding extreme temperature variations and exposure to corrosive substances. Proper alignment is essential; ensure the valve body is positioned correctly with the piping to prevent undue stress on the valve and connections.

Tips: Always use manufacturer-recommended gaskets and seals to avoid leaks and maintain integrity. Additionally, implement a thorough torqueing procedure for the flange bolts, applying the recommended torque values in a cross-pattern to evenly distribute pressure.

Before commissioning the valve, conduct a thorough inspection for any manufacturing defects or damage that may have occurred during shipping or storage. Ensure that the necessary clearance is allowed for maintenance or inspection in the future. Following these practices can significantly enhance the longevity and efficiency of API bellows sealed globe valves, providing reliable service across a range of industrial processes.

Api bellows sealed globe valves are increasingly utilized in various industrial applications due to their unique design and operational benefits. One of the most notable features of these valves is their ability to prevent leakage, which is essential in industries where fluid containment is critical. This attribute makes them particularly suitable for handling hazardous and corrosive materials, ensuring both safety and environmental compliance.

Common applications for these valves can be found in the chemical processing and oil and gas sectors, where reliable fluid control is paramount. Their robustness also extends to HVAC systems and power plants, where durability and performance under high pressure are essential. Furthermore, the ease of operation of these valves, as highlighted by recent innovations in valve technology, enhances efficiency in industrial processes. Manufacturers are continually developing improved valve designs, which further solidifies the role of bellows sealed globe valves as a key component in modern industrial operations.