+86 19720579616

+86 19720579616

Zalo

Zalo

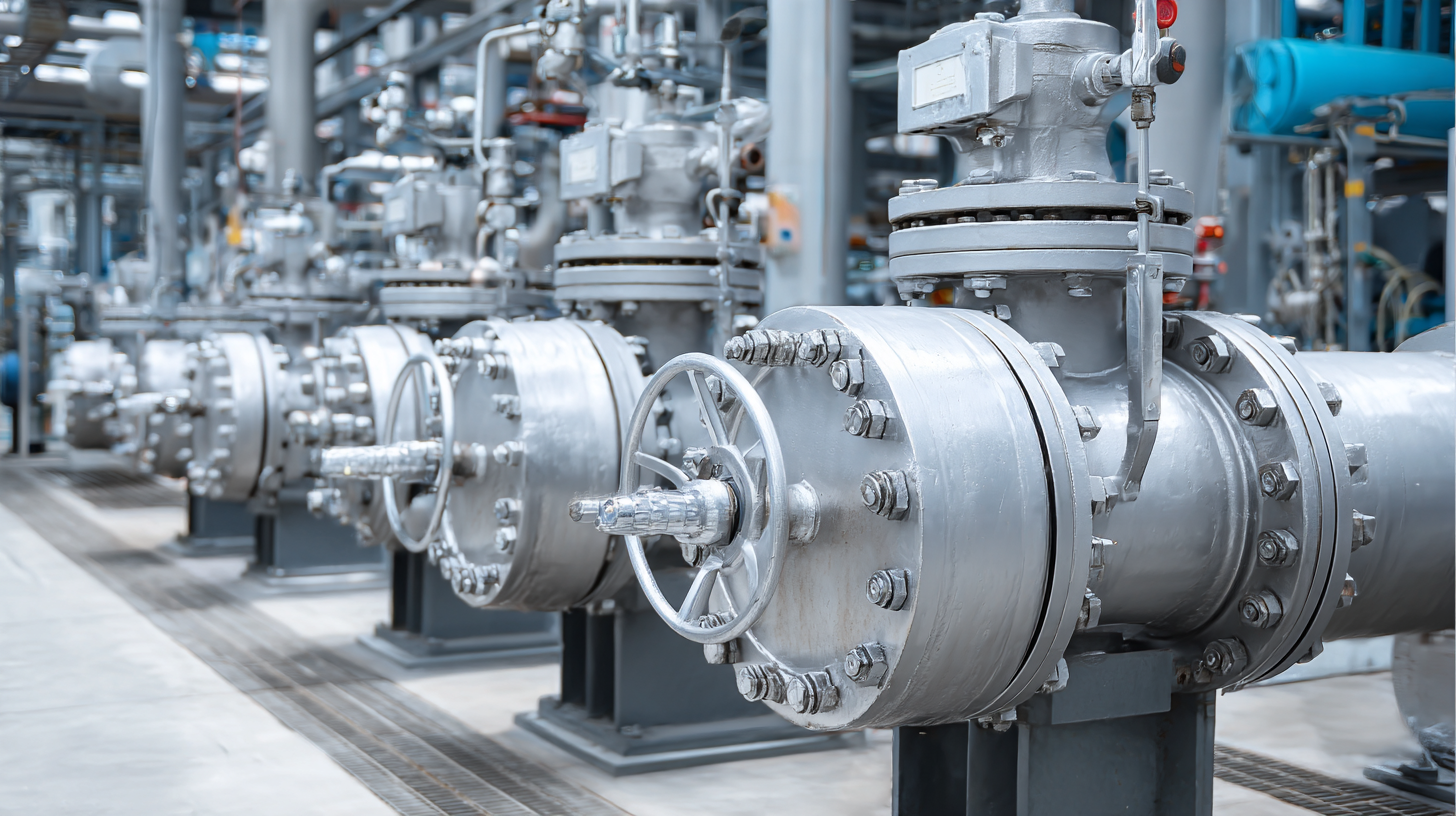

In the rapidly evolving landscape of modern industrial applications, the demand for reliable and efficient control mechanisms has never been greater. A pivotal component in achieving this is the implementation of API Bellows Sealed Gate Valves, which are engineered to enhance performance while minimizing leakages. According to a recent report by MarketsandMarkets, the global valve market is projected to reach USD 90 billion by 2025, with bellows sealed valves witnessing a significant surge in adoption across sectors such as oil and gas, water treatment, and pharmaceuticals. The unique design of API Bellows Sealed Gate Valves not only ensures tight sealing but also protects the environment from harmful emissions, aligning with stringent regulatory standards. As industries increasingly prioritize safety and environmental sustainability, understanding the multifaceted benefits of these specialized valves becomes crucial for optimizing operational efficiency and compliance in contemporary systems.

API bellows sealed gate valves are increasingly favored in high-pressure industrial environments due to their unique design and functionality. Unlike traditional gate valves, the bellows seal effectively isolates the actuator and stem from the fluid medium, minimizing the risk of leaks. This feature is particularly crucial in high-pressure applications where even minor leaks can pose significant safety hazards and lead to costly downtime. The bellows act as a barrier against extreme pressures, ensuring that the system remains secure and operational.

Another key advantage of these valves is their ability to withstand corrosive substances commonly found in industrial settings. The materials used for the bellows and valve body can be selected to resist corrosion, which significantly extends the lifespan of the valve and reduces maintenance costs. Furthermore, the robust construction of API bellows sealed gate valves allows them to maintain integrity and performance even under fluctuating pressures, providing reliability that manufacturers and operators depend on. This combination of leak prevention and durability makes API bellows sealed gate valves an optimal choice for modern industrial applications where safety and efficiency are paramount.

This chart illustrates the advantages of API Bellows Sealed Gate Valves in various industrial applications, focusing on their effectiveness in high-pressure environments. The data represents performance benefits such as leak prevention, durability, maintenance efficiency, and operating pressure range.

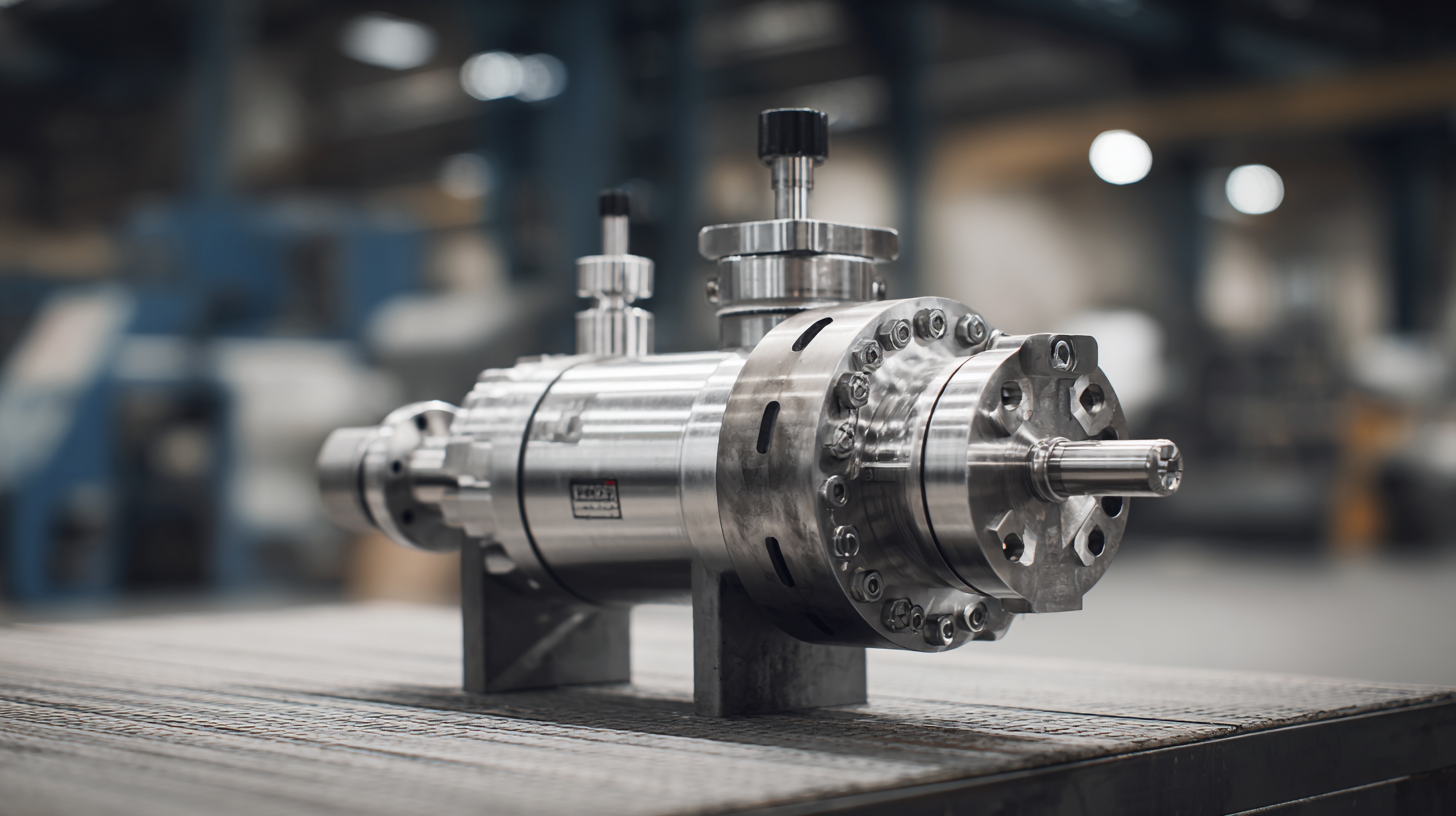

In modern industrial applications, maintaining the integrity of fluid systems is paramount. API bellows sealed gate valves provide a robust solution to prevent contamination, thanks to their innovative bellows seals. These seals effectively isolate the valve's moving parts from the medium, significantly reducing the risk of leakage and external contaminants entering the system. This enhanced durability is crucial for industries that handle hazardous or sensitive materials, ensuring safe and reliable operations.

Tips: Regular maintenance of bellows sealed gate valves can extend their lifespan. Inspect the bellows for any signs of wear or fatigue, and ensure that the connections are tight to prevent potential leaks. Additionally, utilizing appropriate lubricants can help maintain the smooth operation of the valve while preserving the integrity of the seals.

By employing bellows seals, industrial facilities can experience less downtime and reduced costs associated with repairs or replacements. The design of bellows sealed gate valves also allows for easier installation and operation, making them an efficient choice in various applications, from chemical processing to water treatment.

API bellows sealed gate valves have become a cornerstone in modern industrial applications due to their remarkable cost-effectiveness. These valves are designed with a bellows sealing mechanism that significantly reduces the risk of leakage, leading to lower maintenance costs over time. According to a recent study by the Industrial Valve Association, incorporating bellows sealed valves can reduce maintenance expenditures by up to 30%. The sturdy design and reduced wear and tear from minimal leakage directly contribute to long-term savings for companies.

In addition to the initial savings in maintenance, these valves enhance operational efficiency. The American Society of Mechanical Engineers (ASME) reports that using high-quality API bellows sealed gate valves can increase system reliability and longevity, resulting in fewer unexpected downtimes. This reliability translates not only to financial savings but also to improved safety standards within industrial settings.

**Tip:** When selecting valves for your application, prioritize those that meet industry standards such as API 626 or ASME B16.34. This can guarantee performance and reliability, ultimately leading to substantial savings in both maintenance and operational costs.

**Tip:** Regularly review your valve maintenance schedules and consider the long-term implications of using traditional versus bellows sealed valves. An initial investment in higher-quality valves can yield significant returns through reduced operational disturbances and repair needs.

API bellows sealed gate valves are gaining traction in modern industrial applications due to their versatility and effectiveness in various processes. These valves are particularly suitable for industries that require reliable isolation and minimal leakage, such as chemical processing, oil and gas, and water treatment. Their design, featuring a flexible bellows sealing mechanism, allows for tight sealing, which is essential for handling corrosive and hazardous materials. This makes them an ideal choice for operations where safety and environmental considerations are paramount.

In addition to their robust sealing capabilities, API bellows sealed gate valves are favored in processes that involve high-temperature and high-pressure conditions. The durability of the bellows ensures that the valves can withstand extreme operational demands without compromising on performance. Industries such as power generation and pharmaceuticals benefit from the consistent reliability and lower maintenance needs of these valves. This adaptability not only enhances operational efficiency but also reduces downtime, reinforcing their status as a critical component in modern industrial systems.

Bellows sealed gate valves are increasingly recognized for their significant contributions to sustainability in industrial applications. By preventing leakage, these valves not only enhance operational efficiency but also protect the environment from harmful emissions. The development of innovative technologies aimed at improving valve sealing mechanisms highlights the industry's commitment to reducing environmental impact. Recent advancements, such as zero leak magnetic valve technology, showcase how the integration of modern solutions can lead to a drastic reduction in emissions, aligning with global sustainability goals.

Bellows sealed gate valves are increasingly recognized for their significant contributions to sustainability in industrial applications. By preventing leakage, these valves not only enhance operational efficiency but also protect the environment from harmful emissions. The development of innovative technologies aimed at improving valve sealing mechanisms highlights the industry's commitment to reducing environmental impact. Recent advancements, such as zero leak magnetic valve technology, showcase how the integration of modern solutions can lead to a drastic reduction in emissions, aligning with global sustainability goals.

Moreover, as industries strive for safer and more reliable operations, the focus on leak-free performance becomes critical. The introduction of numerical models to study the erosion rates in gas-solid flow and the optimization of valve structures further demonstrates how engineering improvements can bolster safety standards while minimizing negative environmental effects. By investing in advanced sealing technologies and rigorous testing methodologies, businesses can not only enhance their operational reliability but also significantly contribute to broader sustainability efforts, making a positive impact on the environment.