+86 19720579616

+86 19720579616

Zalo

Zalo

In modern industrial applications, the selection of appropriate valve materials is crucial for ensuring system efficiency and durability. Among the various options available, Forged Steel Valves have gained significant traction due to their superior strength and reliability in high-pressure environments. According to a report by Market Research Future, the global valve market is projected to reach USD 122.29 billion by 2025, with forged steel valves accounting for a substantial share due to their ability to withstand extreme temperatures and corrosive substances. The inherent toughness of forged steel allows these valves to maintain structural integrity under fluctuating pressures, making them ideal for use in critical sectors such as oil and gas, chemical processing, and power generation. Therefore, understanding the advantages of forged steel valves not only informs purchasing decisions but also enhances the overall performance and safety of industrial systems.

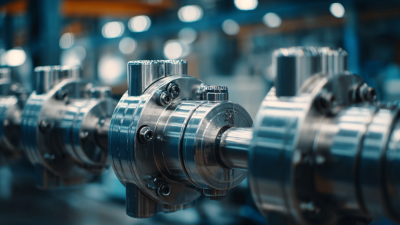

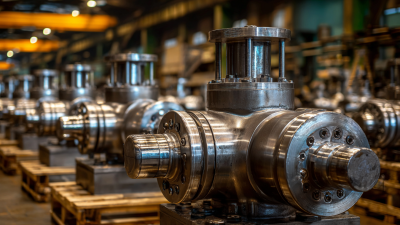

The production process of forged steel valves is pivotal in various industrial applications, particularly due to their enhanced performance and reliability. Forged valves are created through a method that applies compressive forces to steel at high temperatures, leading to a finely structured material that exhibits superior strength and durability. This process not only improves the mechanical properties of the valves but also enables manufacturers to control the material more effectively during production, ensuring a high-quality final product that meets the rigorous demands of sectors such as oil and gas, water management, and chemical processing.

Recent industry reports suggest that the global industrial valve market is expected to grow significantly, estimated to be worth around $95.58 billion by 2024 and projected to reach approximately $121.67 billion soon thereafter. As industries increasingly demand valves that can withstand high pressures and corrosive environments, forged steel valves are becoming the preferred choice due to their exceptional resistance to wear and fatigue. Moreover, innovations such as hydroformed diaphragm valve bodies highlight the trend toward sustainable and efficient manufacturing processes, further solidifying forged steel valves' roles as indispensable components in critical fluid control applications.

Forged steel valves offer a myriad of advantages when it comes to managing high-pressure environments, making them a preferred choice in various industrial applications. One of the primary benefits is their superior strength and durability compared to other valve materials. The forging process enhances the microstructure of the steel, resulting in a tough and resilient component that can withstand extreme pressures and temperatures. This robustness is crucial in sectors such as oil and gas, power generation, and chemical manufacturing, where safety and reliability are paramount.

Another significant advantage of forged steel valves is their ability to provide a tight seal under high-stress conditions. They are designed to minimize leakage, which is essential for preventing hazardous material escape and ensuring operational efficiency. Additionally, these valves often feature more compact designs, allowing for easier installation in confined spaces without compromising performance. Their resistance to wear and corrosion further extends their lifespan, making them a cost-effective solution in demanding applications where maintenance and downtime can be costly.

When examining the durability of valves in industrial applications, forged steel valves stand out significantly compared to their cast steel counterparts. The primary reason for this difference lies in the manufacturing process; forged steel is created through compressive forces, which align the material's internal structure for improved strength and toughness. In contrast, cast steel valves are poured and allowed to solidify, making them more susceptible to defects and weakening under stress. This results in forged steel valves often exhibiting superior performance in high-pressure and high-temperature environments.

Tips: When choosing between forged and cast steel valves, consider the specific application requirements. Forged valves may be more suitable for critical systems that require high reliability and resistance to fatigue. Additionally, investing in forged valves can lead to long-term cost savings due to reduced maintenance needs and longer service life.

Moreover, the enhanced durability of forged steel valves means they are less likely to fail under extreme conditions. This resilience is crucial for operations in industries such as oil and gas, where unexpected valve failure can lead to significant downtime and financial loss. By opting for forged steel, businesses can ensure smoother operations and better overall equipment reliability.

Tips: Always consult with a manufacturer or an expert to determine the most appropriate valve type for your operation, based on the pressure, temperature, and corrosive factors present in your processes.

Forged steel valves play a crucial role in various industrial applications due to their enhanced strength and durability. These valves are widely used in sectors such as oil and gas, power generation, chemical processing, and water treatment. In the oil and gas industry, for example, forged steel valves can withstand high-pressure conditions, ensuring safe and efficient operation in pipelines. Their ability to handle extreme temperatures makes them ideal for power generation applications, where reliability is paramount.

**Tip:** When selecting forged steel valves, consider the specific environmental conditions they will operate in. Matching the valve material with the application’s temperature and pressure parameters can extend its lifespan and improve overall performance.

In the chemical processing industry, forged steel valves are essential for managing corrosive substances, thanks to their robust construction. These valves provide excellent sealing capabilities, reducing the risk of leaks that can lead to hazardous situations. Moreover, in water treatment facilities, their resistance to wear and tear ensures the consistent performance of the water distribution systems.

**Tip:** Regular maintenance checks on forged steel valves can prevent unexpected failures. Ensuring that seals and moving parts are in good condition helps maintain the integrity of the system and optimizes operational efficiency.

Forged steel valves are synonymous with durability and reliability in industrial applications. However, ensuring their longevity requires proper maintenance. Regular inspection is essential; operators should examine valves for signs of wear, particularly at sealing surfaces and in the body. According to industry data, routine maintenance can extend the lifespan of forged steel valves by as much as 50%. Using appropriate lubricants and ensuring that the valve is operated within its design parameters are crucial practices that prevent premature wear and failure.

In addition to regular inspections, addressing any operational anomalies immediately can prevent minor issues from escalating. This proactive approach is crucial, as the failure to maintain valve integrity can lead to significant downtime and costly repairs. Implementing a comprehensive maintenance schedule that adheres to manufacturer guidelines can significantly enhance performance longevity. Reports suggest that properly maintained forged steel valves can exceed operational periods of 20 years, which is essential for industries reliant on efficient and sustained operations. Adopting these practices not only maximizes the benefits of forged steel valves but also contributes to overall operational efficiency.