0102030405

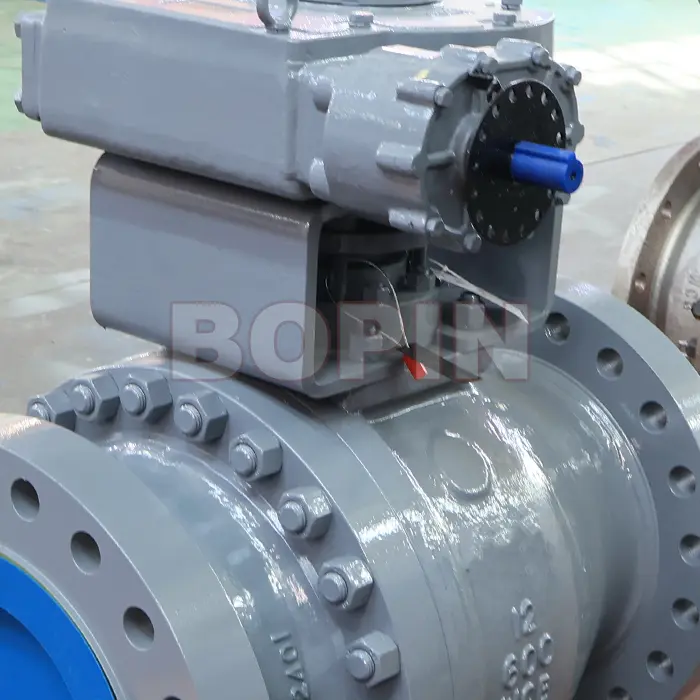

API 6D 2PC SPLIT BODY CAST STEEL TRUNNION MOUNTED BALL VALVES

About API 6D Standard

The API 6D standard was established by the American Petroleum Institute (API) to set the specifications for pipeline valves used in the oil and gas industry. It outlines the requirements for the design, materials, testing, and performance of valves to ensure reliability and safety in critical applications. The API 6D standard covers various types of valves, including ball valves, gate valves, and check valves. For an API 6D valve to meet industry standards, it must pass a series of rigorous tests, including pressure testing, mechanical testing, and functional testing. This ensures that the valve will perform as expected under different pressure and temperature conditions, and in challenging operating environments.

The Material of A216 WCB Cast Steel

The A216 WCB material is a carbon steel specification used in valve construction. A216 refers to the ASTM (American Society for Testing and Materials) standard that defines the requirements for carbon steel castings used in pressure-containing parts. The WCB grade is a common carbon steel used for valves and other pressure-containing components due to its excellent mechanical properties and ability to withstand moderate temperatures and pressures.

Material Properties of A216 WCB:

Composition: The composition of WCB steel typically includes carbon (0.30–0.60%), manganese (0.60–0.90%), silicon (0.30–0.60%), and traces of sulfur, phosphorus, and copper.

Strength: WCB has good strength characteristics, making it suitable for use in pipelines and pressure vessels.

Temperature Resistance: WCB can operate in a temperature range from -20°F to 800°F (-29°C to 427°C).

Corrosion Resistance: While WCB is resistant to many corrosive environments, it is not suitable for applications involving aggressive chemicals. For highly corrosive conditions, a different material like stainless steel or alloy may be used.

This material is typically chosen for its balance of strength, durability, and cost-effectiveness.

Design of Flanged Trunnion Mounted Ball Valve

Trunnion Mounted Ball Valve Design

A trunnion-mounted ball valve differs from a standard floating ball valve in that it features a ball that is supported by a trunnion, or a pair of shafts, which hold the ball in place. These shafts are typically connected to the valve body and help to bear the pressure load during operation. The trunnion mounting ensures that the ball is less susceptible to the effects of high-pressure changes, providing more stability and a longer lifespan compared to floating ball valves.

Key Features of Trunnion Mounted Ball Valves:

Reduced Seat Wear: The trunnion-mounted ball is supported by the trunnions, which reduces the contact between the ball and the seat. This helps prevent seat damage due to high-pressure differentials.

Torque Control: The trunnion design provides better control over the torque needed to operate the valve, especially in high-pressure conditions.

High Flow Capacity: Trunnion mounted ball valves can offer better flow characteristics due to their design, making them suitable for high-flow applications.

Flanged Connection

The flanged connection refers to the method by which the valve is connected to the pipeline. A flange is a flat surface with holes for bolts, which allows the valve to be securely bolted to the pipe. Flanged connections are widely used due to their simplicity, ability to handle high-pressure conditions, and ease of maintenance.

The flanged connection refers to the method by which the valve is connected to the pipeline. A flange is a flat surface with holes for bolts, which allows the valve to be securely bolted to the pipe. Flanged connections are widely used due to their simplicity, ability to handle high-pressure conditions, and ease of maintenance.

Operating Principle

The operation of a trunnion mounted ball valve is fairly straightforward. The valve consists of a spherical ball with a hole in the center, which is rotated to allow or block fluid flow. When the valve is open, the hole in the ball is aligned with the pipe, allowing the fluid to pass through. When the valve is closed, the ball is rotated 90 degrees so that the hole is perpendicular to the flow, blocking the passage of fluid.

The trunnion design ensures that the ball is securely supported at both the top and bottom, minimizing the force required to rotate the valve and providing added stability. The ball is typically driven by an actuator or manual handle, and the valve can be operated with minimal effort even under high-pressure conditions.

Applications

The API 6D A216 WCB Cast Steel Flanged Trunnion Mounted Ball Valve is commonly used in various industries for controlling the flow of liquids and gases. Its design makes it ideal for high-pressure and high-flow applications where reliability and performance are paramount.

Common Applications Include:

Oil and Gas Industry: For controlling the flow of crude oil, natural gas, and other hydrocarbons in pipelines. Trunnion mounted ball valves can withstand the high pressures found in subsea or upstream oil and gas applications.

Chemical Processing: Used to control the flow of chemical substances, these valves are reliable in handling a range of chemical reactions.

Water Treatment: Trunnion ball valves can be found in water filtration and distribution systems, where they control the flow of treated water.

Power Generation: In power plants, these valves regulate the flow of steam, water, or fuel to ensure efficient plant operations.

HVAC Systems: Used to control the flow of air or water within large-scale heating, ventilation, and air conditioning systems.

Advantages of Trunnion Mounted Ball Valves

Improved Stability: Due to the trunnion design, the ball remains securely fixed during operation, reducing wear and tear caused by high-pressure differentials.

Low Torque: The trunnion mounting reduces the friction between the ball and the seats, requiring less torque to operate the valve.

Reliable Performance: The robust design ensures that the valve performs well in extreme conditions, such as high-pressure or high-temperature environments.

Lifespan: Longer Because the ball is supported at two points, the valve experiences less wear and tear compared to floating ball valves, leading to a longer operational life.

Maintenance Considerations

Proper maintenance is essential to ensure the longevity and performance of any valve, including the API 6D A216 WCB Cast Steel Flanged Trunnion Mounted Ball Valve. Regular inspections, testing, and servicing are required to keep the valve in optimal working condition.

Maintenance Best Practices:

Inspect Seals and Seats: The valve's seals and seats should be regularly checked for wear or damage. Replacing worn-out seals can help prevent leakage and ensure proper sealing.

Lubrication: Moving parts, such as the trunnion shafts and ball, should be lubricated periodically to prevent corrosion and ensure smooth operation.

Pressure Testing: Regular pressure testing ensures that the valve can withstand operating conditions without failure.

Cleaning: Keep the valve free from debris and buildup, which can impede operation and cause wear.