0102030405

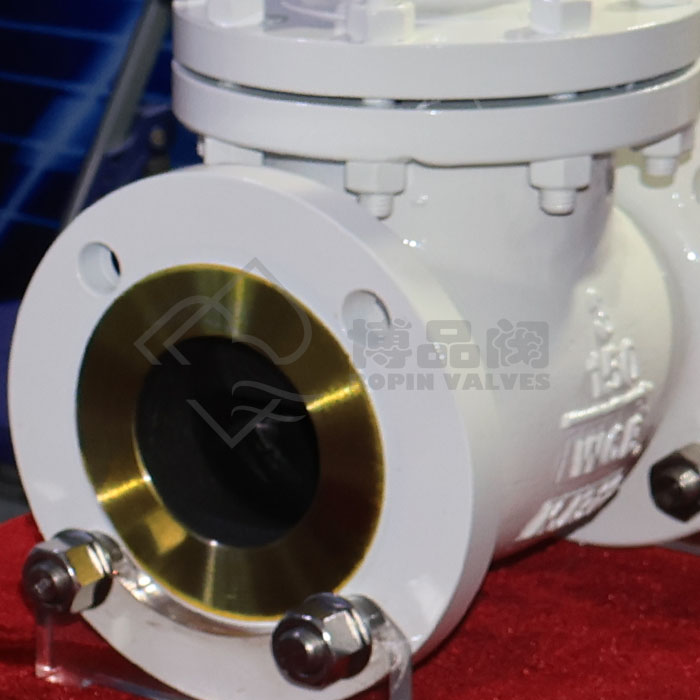

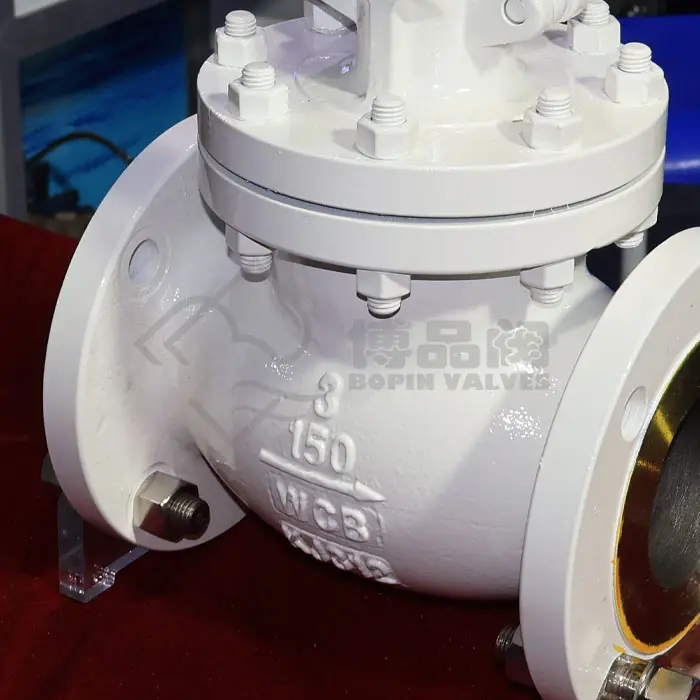

API 623 BS 1873 A216 WCB Cast Steel Globe Valve

What Is Lift Type?

The API 623 BS 1873 A216 WCB Cast Steel Globe Valve is designed to provide superior flow control in a variety of industrial processes. Below are its primary features and design considerations:

1.1 Cast Steel Body (A216 WCB)

The A216 WCB material is a carbon steel casting commonly used for valve bodies due to its excellent strength and resistance to corrosion. WCB refers to the specific grade of carbon steel, which is heat-treated to ensure durability. This material is well-suited for high-pressure and high-temperature environments typically encountered in industrial systems.

1.2 Globe Valve Design

The globe valve is one of the most commonly used valve types for controlling fluid flow in pipelines. It has a spherical body with an internal baffle that divides the flow into two paths. The flow is controlled by a plug or disc that moves along the valve's stem. By adjusting the position of the plug, the valve can modulate the flow of fluid, allowing for both throttling and full shutoff.

1.3 Throttling Capability

One of the primary advantages of the globe valve is its ability to provide precise throttling control. Unlike ball or gate valves, which are designed for full open or full shutoff, globe valves allow for incremental changes in the flow rate, making them ideal for applications requiring fine control of fluid flow.

1.4 Flanged Connections

The flanged design allows the valve to be securely bolted to the piping system, ensuring a tight, leak-free connection. Flanged connections are typically standardized to industry dimensions, making the valve easy to integrate into most systems.

1.5 Bonnet and Stem Assembly

The bonnet houses the stem and actuator, providing the structural support needed for smooth operation. The stem transmits the motion from the actuator to the valve plug, controlling its position. This assembly is designed for durability, ensuring the valve operates smoothly over an extended service life.

1.6 Adjustable Packing

The valve stem is equipped with adjustable packing to prevent leakage along the stem. Over time, the packing can be tightened to compensate for wear and maintain a tight seal.

1.7 Pressure and Temperature Rating

The API 623 standard specifies pressure and temperature ratings for valves based on their construction material. The A216 WCB cast steel construction allows the valve to operate in high-pressure systems, typically rated up to 2500 PSI or higher, and can handle temperatures ranging from -20°F to 800°F (-29°C to 427°C), depending on the specific design.

2. Advantages of API 623 BS 1873 A216 WCB Cast Steel Globe Valve

The API 623 BS 1873 A216 WCB Cast Steel Globe Valve offers several key advantages that make it an ideal choice for fluid control in industrial applications:

2.1 Precise Flow Control

The primary benefit of the globe valve is its ability to provide precise control of fluid flow. The valve plug’s movement along the stem allows for fine adjustments to the flow, making it ideal for applications that require throttling or regulation.

2.2 High Durability

Constructed from A216 WCB cast steel, the valve is capable of withstanding high mechanical stresses and harsh environmental conditions. It offers excellent resistance to wear and corrosion, making it suitable for long-term use in high-pressure and high-temperature systems.

2.3 Versatility

The API 623 BS 1873 A216 WCB Cast Steel Globe Valve is suitable for a wide range of industrial applications. It is commonly used in oil and gas pipelines, power plants, chemical processing units, water treatment plants, and other systems where fluid flow control is essential.

2.4 High Shutoff Capability

The valve is designed to provide an effective shutoff function, ensuring complete isolation of the fluid flow when the valve is fully closed. This feature is critical for maintaining safety and controlling system pressure during maintenance or emergencies.

2.5 Robust Design

With its cast steel body, the valve is engineered for high performance under demanding conditions. The A216 WCB material ensures that the valve remains functional under high pressure and temperature fluctuations, providing reliable performance over its lifespan.

2.6 Easy Maintenance

The API 623 standard provides guidelines for the valve’s maintenance, ensuring that it can be serviced efficiently. Key components such as the stem, packing, and disc are designed for easy replacement or adjustment, reducing downtime and maintenance costs.

3.Applications of API 623 BS 1873 A216 WCB Cast Steel Globe Valve

The API 623 BS 1873 A216 WCB Cast Steel Globe Valve is used in a broad spectrum of industries due to its ability to regulate and control the flow of fluids accurately. Here are some common applications:

3.1 Oil and Gas Industry

In oil and gas pipelines, this globe valve is used to control the flow of crude oil, natural gas, or refined products. It is commonly employed in upstream operations for exploration and production, as well as in midstream and downstream systems for transporting and processing these materials.

3.2 Power Generation

In power plants, the API 623 globe valve is used to regulate steam, water, and other fluids within the plant’s systems. Its throttling capability is crucial for managing pressure, temperature, and flow in boiler feedwater systems, turbine bypass systems, and cooling water circuits.

3.3 Chemical Processing

The valve is widely used in chemical processing industries to regulate the flow of chemicals, solvents, and other fluids used in production. It ensures that the correct amounts of each fluid are supplied to different parts of the process, preventing overpressure and maintaining optimal operating conditions.

3.4 Water Treatment

In water treatment plants, globe valves help regulate the flow of water through various treatment stages, such as filtration, disinfection, and chemical dosing. Precise flow control is essential to maintain water quality and ensure that the treatment processes are efficient.

3.5 HVAC Systems

In HVAC (heating, ventilation, and air conditioning) systems, the valve regulates the flow of air or water through ducts, pipes, and heat exchangers. It ensures proper temperature control and airflow throughout a building, ensuring efficient operation of the HVAC system.

4.Maintenance and Care

Proper maintenance is essential to ensure that the API 623 BS 1873 A216 WCB Cast Steel Globe Valve continues to operate efficiently throughout its service life. Below are key maintenance practices:

4.1 Regular Inspection

Regular visual inspection is necessary to check for signs of leakage around the packing, stem, and valve seat. Look for any visible cracks, corrosion, or wear in the valve body, bonnet, and other components.

4.2 Stem and Packing Maintenance

The stem should be lubricated periodically to ensure smooth operation. If there are any signs of excessive friction, the packing should be adjusted or replaced to maintain a tight seal and prevent leakage.

4.3 Valve Seat Inspection

The valve seat should be inspected for erosion or wear caused by continuous fluid flow. Any damage to the seat may affect the valve’s ability to seal properly, leading to leaks and loss of control. If the seat is damaged, it should be resurfaced or replaced.

4.4 Cleaning and Debris Removal

Clean the valve periodically to remove any debris or buildup that may obstruct the flow path. This is particularly important in systems where the fluid may contain solids, such as in wastewater treatment or chemical processing applications.

4.5 Testing for Performance

Test the valve periodically by actuating it through its full range of motion to ensure that it responds appropriately and that flow control remains precise. Ensure that the valve fully closes when required and that there is no unintended leakage.

5.Summary

The API 623 BS 1873 A216 WCB Cast Steel Globe Valve is a highly versatile and durable valve designed to regulate fluid flow in a wide range of industrial applications. Its precise throttling capabilities, combined with its strong cast steel construction, make it an essential component for managing fluid control in challenging environments. Whether used in the oil and gas, power generation, chemical processing, or water treatment industries, this valve ensures efficient and reliable performance, providing a long service life when properly maintained.