0102030405

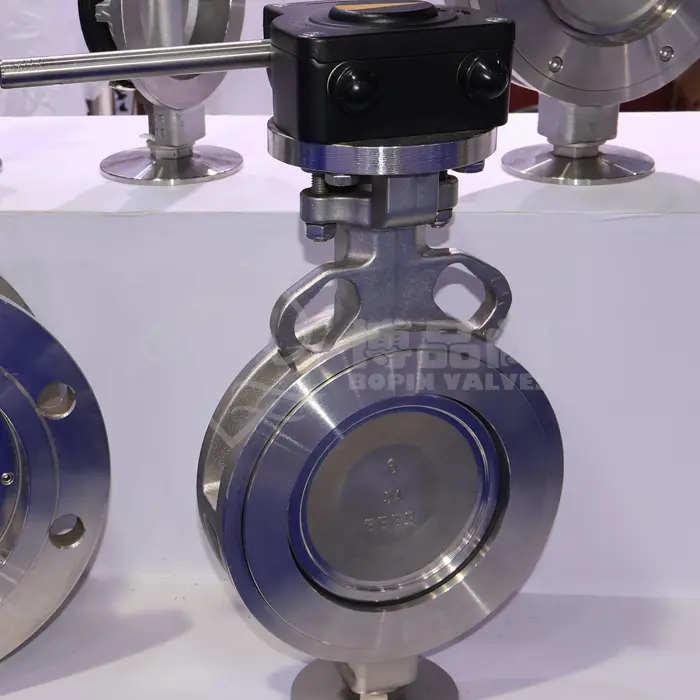

API 609 Wafer Type Double Offset Soft Sealed High Performance Butterfly Valves

1. Design Overview

1.1 Wafer Type

The wafer type butterfly valve is a compact design, which is typically sandwiched between two flanges without the need for a separate valve body or mounting brackets. This makes it an economical option, as it reduces the weight and cost of installation.

The wafer type is particularly advantageous when space is limited or when installation in confined areas is necessary. It is also easier to retrofit into existing pipelines, making it a popular choice in both new installations and system upgrades.

1.2 Double Offset Design

The double offset (or eccentric) design refers to the positioning of the valve stem and disc relative to the pipe’s centerline. In a double offset butterfly valve, the shaft is offset from the center of the valve body, and the valve disc is also offset from the axis of rotation.

The double offset provides several advantages:

Reduced Wear: The offset design allows the disc to rotate more easily and provides smoother operation, which reduces wear on both the disc and seat.

Improved Sealing: The movement of the valve disc off-center allows for better contact with the sealing surfaces, ensuring tighter sealing when the valve is closed.

Minimal Torque: The design requires less torque to operate the valve, which reduces the risk of valve failure and enhances the lifespan of the valve.

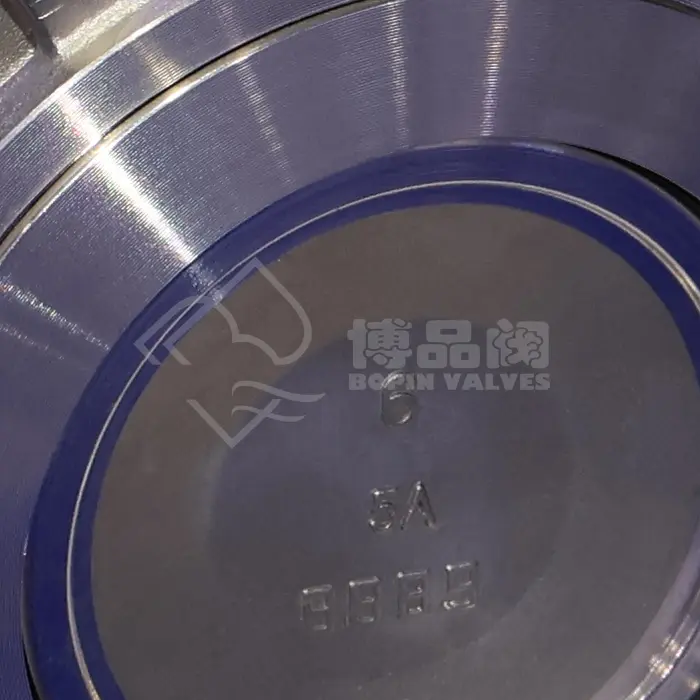

1.3 Soft Sealing

Soft-sealed butterfly valves incorporate a flexible seat material, often made from elastomers such as EPDM, Viton, or PTFE. The seat is designed to form a tight seal when the valve is closed, preventing any leakage of fluids.

The soft sealing feature offers several benefits:

Tight Shut-off: The soft seat can achieve a bubble-tight shut-off, ensuring there is no leakage even under high pressure.

Temperature and Chemical Resistance: The sealing materials used in soft-sealed valves are designed to handle a wide range of temperatures and chemical environments.

Noise Reduction: The soft material can absorb vibrations, reducing noise during valve operation, which is especially beneficial in noise-sensitive applications.

1.4 High Performance

The term “high performance” refers to the valve's ability to function efficiently under demanding conditions, such as high-pressure or high-temperature environments, and provide a reliable seal over long periods of use. High-performance butterfly valves can control the flow of fluids with precision, providing enhanced regulation and control compared to standard valves.

In addition to soft sealing, the high-performance features also include:

Higher Pressure Rating: These valves are designed to handle higher pressures than conventional butterfly valves.

Extended Service Life: The materials and design ensure longer-lasting performance, reducing the need for frequent maintenance.

Corrosion Resistance: High-performance valves are often made from materials that offer excellent corrosion resistance, making them ideal for harsh environments.

2. Key Features and Benefits

2.1 Flow Control Capabilities

The primary function of an API 609 wafer type butterfly valve is to control the flow of liquids or gases within a pipeline. The double offset design ensures a quick and efficient response when opening or closing the valve, making it suitable for applications where precise flow regulation is essential.

With its high-performance features, the valve is capable of handling higher flow rates without sacrificing the stability or integrity of the valve seat. This is especially important in systems where flow consistency and reliability are critical.

2.2 Tight Shut-off

One of the defining features of a high-performance butterfly valve is its ability to provide a tight shut-off even under high pressure. The soft sealing material ensures that there is no leakage when the valve is closed, which is essential for preventing the escape of dangerous or expensive fluids.

A tight shut-off is also important for minimizing the environmental impact by reducing the possibility of leaks, especially in industries dealing with hazardous chemicals or gases.

2.3 Versatility

These valves are highly versatile and can be used in a wide range of industries and applications:

Water Treatment: In water treatment plants, where controlling flow and pressure is crucial.

Oil and Gas: For controlling the flow of hydrocarbons, particularly in pipelines with varying pressure conditions.

Chemical Processing: In systems requiring resistance to highly corrosive chemicals.

HVAC Systems: For controlling heating, cooling, and ventilation systems in buildings.

The versatility of the API 609 butterfly valve makes it an ideal solution for many different industries.

2.4 Low Maintenance

Due to the design’s unique features, API 609 high-performance butterfly valves require less maintenance compared to traditional valves. The double-offset design reduces wear and tear on the valve's components, leading to fewer mechanical failures and less frequent replacements. The durable materials used for the seats and seals extend the valve’s service life, making it a cost-effective solution over time.

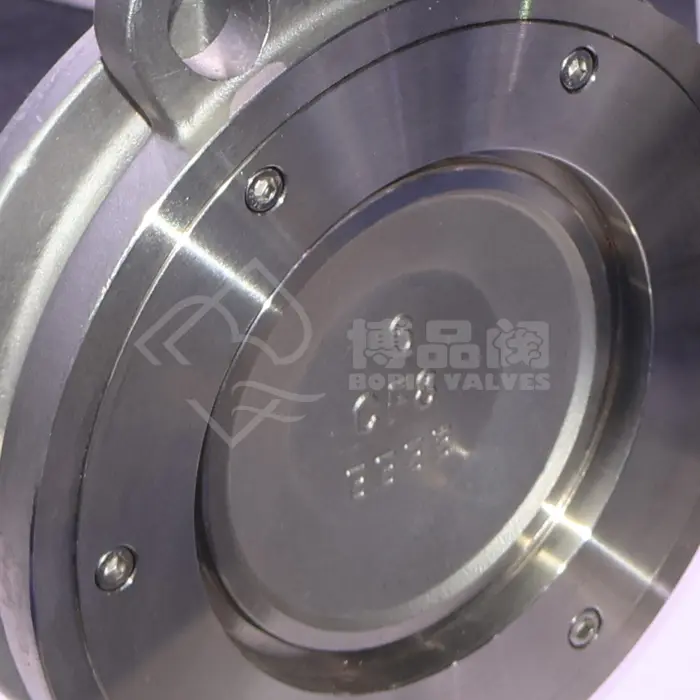

2.5 Space Efficiency

Wafer-type butterfly valves are known for their compact design, which is a major advantage in space-constrained installations. They take up less room than other valve types, making them ideal for areas where installation space is limited. Additionally, their lightweight construction reduces the overall weight of the valve assembly, making them easier to handle and install.

3. Applications

3.1 Industrial Applications

The API 609 wafer type double offset butterfly valve is widely used in industries such as:

Power Generation: For steam, gas, or liquid flow control in power plants.

Oil and Gas: For pipeline flow control, including offshore and onshore applications.

Chemical and Petrochemical: For handling corrosive and high-temperature fluids.

Water and Wastewater: In pumping stations, filtration systems, and treatment plants.

3.2 Energy Sector

In the energy sector, particularly in oil and gas applications, these valves are often used in high-pressure pipeline systems. The high performance of the valve ensures long-term operation without compromising safety or efficiency. The double-offset design and soft seal make them suitable for both upstream and downstream applications, where precision is essential.

3.3 HVAC

The HVAC industry also benefits from the flexibility of wafer-type butterfly valves. These valves are employed to regulate air, water, or refrigerant flow in heating and cooling systems. The tight shut-off and resistance to wear make these valves ideal for systems with frequent cycling.

4. Materials and Construction

4.1 Body Materials

API 609 valves are typically constructed from materials such as:

Cast Iron: Common in lower-pressure applications.

Carbon Steel: Offers a higher strength-to-weight ratio for more demanding applications.

Stainless Steel: Ideal for corrosive environments, providing excellent resistance to corrosion and high temperatures.

4.2 Seat Materials

The choice of seat material depends on the application’s specific requirements:

EPDM: Excellent for water and wastewater applications.

Viton: Used in applications with aggressive chemicals or high temperatures.

PTFE: Provides superior chemical resistance and low friction.

4.3 Disc Materials

The valve disc is typically made from high-strength materials, such as:

Stainless Steel: Ideal for high-corrosion environments.

Alloy Steel: Offers superior strength and performance under high temperatures.