0102030405

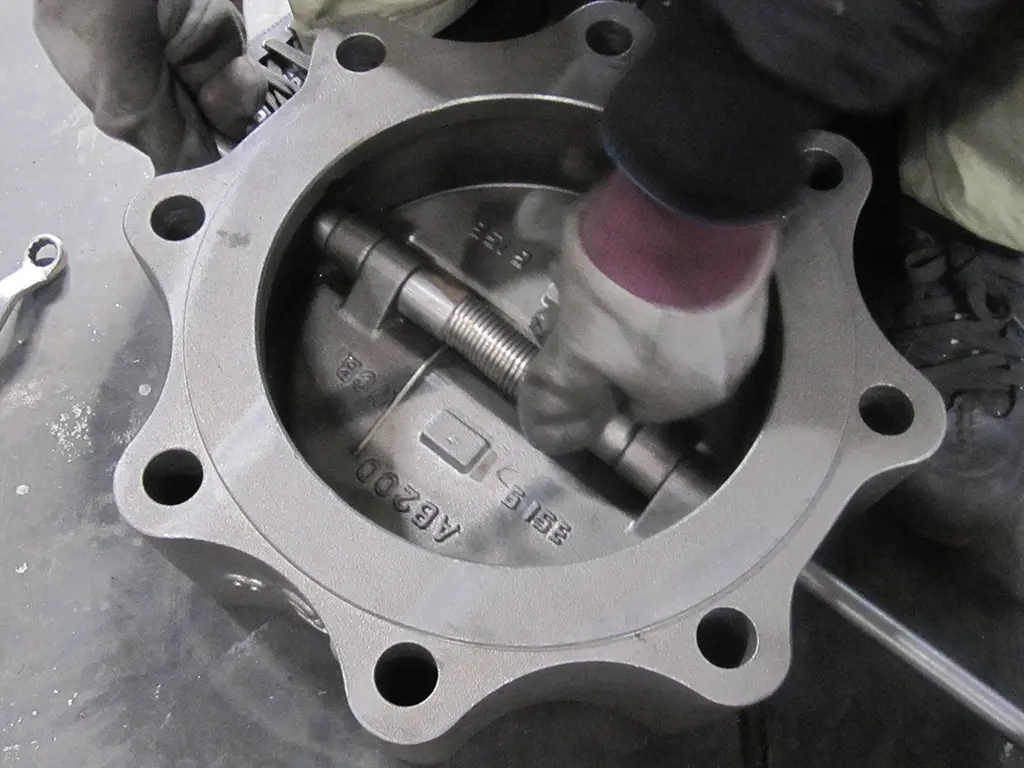

API 594 Wafer Type Dual Plate Check Valve

Design and Construction Features

The API 594 Wafer Type Dual Plate Check Valve is specifically designed for installation between flanges in a pipeline. It features the following key design characteristics:

Wafer Type Design:

The wafer design is characterized by a lightweight and compact structure that fits between flanged pipe connections. Unlike full-bodied valves, the wafer type reduces the overall weight and installation space required, making it ideal for confined or space-limited environments.

Dual Plate Mechanism:

The valve features two hinged plates (or discs) that pivot to open or close the valve. The dual plate configuration ensures that the valve can open and close more efficiently, with less resistance to the flow. The plates are designed to swing open with the flow of fluid and close automatically when the flow reverses, preventing backflow.

Stainless Steel Construction:

The valve is typically made from corrosion-resistant stainless steel, which enhances its durability and resistance to harsh conditions. This makes it suitable for use in aggressive fluid environments such as chemicals, high temperatures, or seawater.

Spring-Assisted Closure (Optional):

Some models may feature spring-loaded mechanisms that help close the plates quickly and reliably, ensuring that backflow is prevented even under low-pressure conditions or when the fluid velocity is low.

Bi-Directional Sealing:

The valve is designed to provide effective sealing in both directions, ensuring a tight closure even when the flow direction is reversed.

How to Work?

The operation of the API 594 wafer type dual plate check valve is straightforward:

Forward Flow: When fluid flows in the intended direction, the force of the fluid pushes the two plates open, allowing it to pass freely through the valve.

Reverse Flow: If the flow reverses, the pressure decreases, causing the two plates to swing shut. The tight seal between the plates prevents the backflow from entering the system.

No Flow Condition: In cases where there is no flow, the plates remain closed, ensuring that there is no leakage.

The design of the dual plates ensures that the valve operates smoothly with minimal pressure drop, making it energy-efficient and reliable.

Advantages of the API 594 Wafer Type Dual Plate Check Valve

Compact and Lightweight:

The wafer design reduces the size and weight of the valve, making it easier to install and ideal for space-constrained installations.

Efficient Backflow Prevention:

The dual plate design allows for faster and more reliable closing, effectively preventing backflow even under fluctuating flow conditions.

Durability:

Constructed from high-quality stainless steel, the valve is durable and resistant to corrosion, making it suitable for use in harsh environments and with aggressive fluids.

Minimal Maintenance:

The simple design with fewer moving parts ensures that the valve requires minimal maintenance and provides long-term reliable service.

Cost-Effective:

The wafer type design and efficient operation make the valve a cost-effective solution, providing reliable backflow prevention without the need for expensive or complex valve types.

Applications

The API 594 wafer type dual plate check valve is commonly used in a variety of industries, including:

Oil and Gas:Protects equipment such as pumps and compressors from reverse flow.

Water Treatment: Prevents backflow in water distribution systems, ensuring clean water integrity.

Chemical Processing: Protects systems from contamination by preventing the backflow of chemicals.

Power Generation: Prevents backflow in steam and water systems, safeguarding turbines and condensers.