0102030405

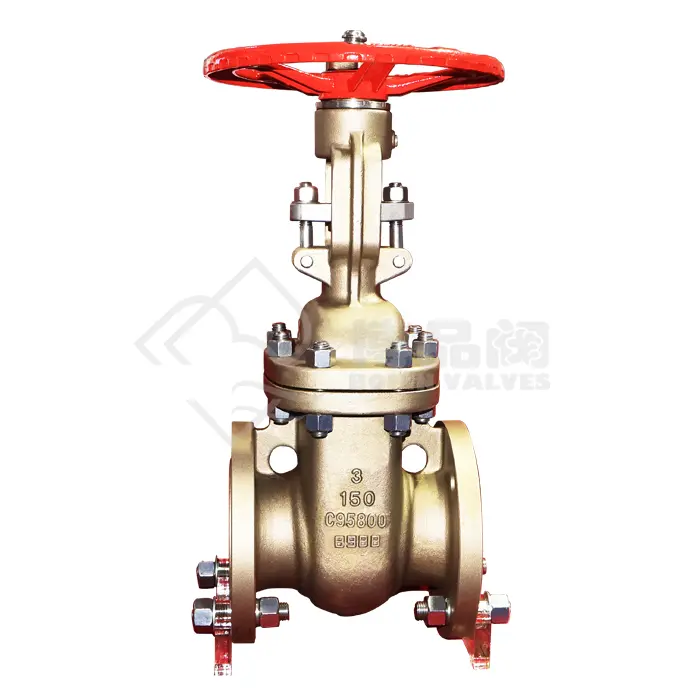

Aluminum Bronze C95800 Gate Valve

1. What is an API 600 Wedged Gate Valve?

The API 600 standard refers to a specification developed by the American Petroleum Institute (API) for the design and manufacturing of gate valves. These valves are commonly used in industries such as oil and gas, petrochemicals, power generation, and water treatment. The Wedged Gate Valve is a specific type of gate valve in which the gate element has a tapered shape, which helps in achieving a reliable sealing mechanism when the valve is closed.

The wedged design ensures a tight seal between the gate and the valve body, preventing leakage and offering long service life under demanding conditions. The "wedged" shape allows for better sealing and easier operation under high-pressure environments, making these valves ideal for critical applications.

2. The Significance of Aluminum Bronze C95800 Material

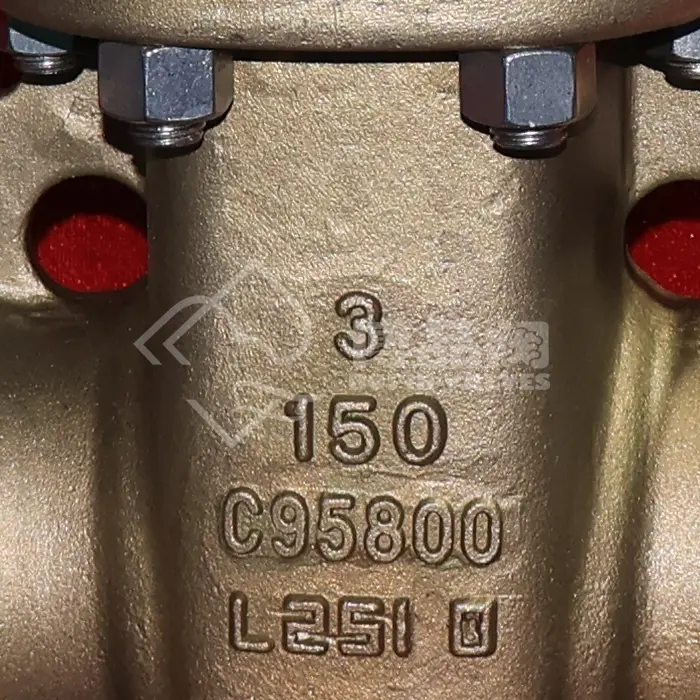

Aluminum bronze is a metal alloy composed primarily of copper with the addition of aluminum and other elements, such as iron, nickel, or manganese. The designation C95800 refers to a specific grade of aluminum bronze alloy, known for its remarkable strength, corrosion resistance, and wear resistance.

The properties of Aluminum Bronze C95800 make it suitable for a wide range of applications. In the context of the Wedged Gate Valve, the benefits of using this material include:

Corrosion Resistance: Aluminum bronze is known for its exceptional resistance to corrosion, especially in saline or marine environments, making it ideal for use in offshore oil rigs, ships, and coastal pipelines.

Strength and Durability: Aluminum bronze C95800 offers high tensile strength and hardness, ensuring that the valve can withstand high pressures and temperatures without losing performance or structural integrity.

Wear Resistance: The alloy's wear-resistant properties ensure that the valve operates smoothly for a long time, even under abrasive conditions.

Thermal Conductivity: Aluminum bronze also offers good thermal conductivity, ensuring the valve can handle temperature variations without compromising its mechanical properties.

3. Features of Aluminum Bronze C95800 API 600 Wedged Gate Valve

API 600 Compliance: The API 600 standard ensures that the valve meets rigorous design, material, and testing criteria for durability and performance. Compliance with this standard is crucial for industries that operate under stringent regulations.v

Wedged Design: The wedged shape of the gate element ensures the valve remains tightly sealed when closed, offering reduced chances of leakage. The wedged mechanism also reduces wear between the gate and seat, enhancing longevity.

Flanged End Connections: The valve is typically designed with flanged end connections, making it easy to install within existing pipeline systems. This type of connection also ensures a secure, leak-proof fit when the valve is closed.

Long Service Life: Due to the corrosion and wear resistance of Aluminum Bronze C95800, the valve can function optimally for many years, reducing maintenance costs and downtime.

High Pressure and Temperature Tolerance: Aluminum bronze C95800 API 600 Wedged Gate Valves are designed to perform in extreme conditions, such as high pressures (up to 2500 psi) and temperatures (up to 800°F or higher).

4. Applications of Aluminum Bronze C95800 API 600 Wedged Gate Valve

Due to its impressive properties, the Aluminum Bronze C95800 API 600 Wedged Gate Valve is suitable for a variety of applications, including but not limited to:

a. Offshore and Marine Applications

Aluminum bronze is widely used in marine environments due to its excellent resistance to corrosion, especially in seawater. This makes the API 600 Wedged Gate Valve a crucial component for pipelines in offshore oil rigs, ships, and other marine installations where corrosion from saltwater is a significant concern.

b. Oil and Gas Industry

The oil and gas industry often operates in high-pressure, high-temperature conditions, requiring valves that can withstand such challenging environments. The Aluminum Bronze C95800 API 600 Wedged Gate Valve is ideal for use in pipelines, refineries, and other critical infrastructure due to its durability and ability to prevent leaks under pressure.

c. Power Generation

In power plants, especially those using steam or other high-temperature fluids, valves must be able to operate under extreme conditions without degradation. The corrosion-resistant properties of Aluminum Bronze make these valves suitable for steam, gas, and cooling water systems in power plants.

d. Water and Wastewater Treatment

In water and wastewater treatment plants, Aluminum Bronze C95800 API 600 Wedged Gate Valves are used to control the flow of water, especially in systems exposed to harsh conditions or aggressive fluids. The material's resistance to corrosion and erosion ensures reliable operation even in environments where other materials might fail.

e. Chemical and Petrochemical Industries

Chemical processing plants often deal with aggressive chemicals and high temperatures. Aluminum Bronze's resistance to a wide range of chemicals makes these valves ideal for use in such applications, ensuring that the pipeline remains sealed and protected.

5. Advantages of Aluminum Bronze C95800 API 600 Wedged Gate Valves

a. Durability and Longevity

Due to the superior strength and resistance of Aluminum Bronze C95800, these valves have an extended service life compared to those made of other materials like carbon steel or stainless steel. This means reduced maintenance, fewer replacements, and increased efficiency in critical operations.

b. Cost-Effectiveness in the Long Run

Although aluminum bronze may be more expensive upfront, its durability, corrosion resistance, and low maintenance requirements make it a more cost-effective choice over the long term. This is particularly true for industries that operate in harsh environments, where valve failure can result in high repair and downtime costs.

c. Excellent Performance in Extreme Conditions

Aluminum Bronze C95800 API 600 Wedged Gate Valves are built to withstand high pressures, temperatures, and corrosive environments. This makes them a reliable choice for industries that need to control the flow of fluids or gases in extreme conditions without risking failure.

d. Low Friction and Wear

The alloy's excellent wear resistance ensures that the valve will continue to operate smoothly even in applications involving abrasive fluids, reducing friction and the risk of failure over time.

6. Considerations When Using Aluminum Bronze C95800 API 600 Wedged Gate Valves

a. Compatibility with Fluids

Although Aluminum Bronze C95800 is resistant to many types of corrosion, it is important to ensure the valve material is compatible with the specific fluid or gas being controlled. Certain aggressive chemicals or extreme conditions may require a more specialized alloy or coating.

b. Installation and Maintenance

While these valves are designed for long service life, proper installation and maintenance are essential for achieving the best performance. Regular inspection, cleaning, and lubrication of moving parts will ensure the valve continues to function optimally.

c. Cost Considerations

Aluminum Bronze C95800 may have a higher initial cost compared to valves made from other materials, such as cast iron or carbon steel. However, the added cost is often justified by its superior performance and extended service life, especially in demanding environments.